2026 Top Industrial Circulation Heaters What to Expect?

Table of Contents

- Overview of Industrial Circulation Heaters in 2026

- Key Features to Look for in 2026 Models of Circulation Heaters

- Emerging Technologies Influencing Circulation Heaters in 2026

- Market Trends Impacting the Industrial Circulation Heater Sector

- Energy Efficiency Standards for Circulation Heaters in 2026

- Safety Features to Expect in New Circulation Heater Designs

- Predicted Major Manufacturers and Their Innovations in 2026

- Optimal Solutions for Heating Air Ducts: Exploring the Benefits of Tubular Heaters

- FAQS

- Conclusion

- Related Posts

As the industrial sector really pushes to become more efficient, we're actually seeing a huge jump in the demand for advanced Industrial Circulation Heaters, and that trend is expected to keep growing until 2026. Industry expert James Anderson from HeatTech Innovations puts it simply: "The future of industrial heating is all about smart tech and energy efficiency." That statement kinda sums up how things are shifting towards smarter, more efficient solutions in the heating game.

The evolution of these heaters is definitely heading towards cooler features, like integrating IoT tech so companies can monitor and tweak things in real-time. That’s a big deal for industries trying to cut down on operational costs. But yeah, it’s not all smooth sailing. A lot of companies are still stuck on old models that just aren’t energy-efficient at all.

Looking ahead, most predictions say that by 2026, those innovative, modern designs will be the standard. That said, some organizations might still hesitate to switch from their traditional setups—mainly because of tight budgets, even if they know that the new tech could save them money in the long run. The path forward isn't totally straightforward, but the upgrades coming to Industrial Circulation Heaters definitely promise some pretty impressive improvements down the line.

Overview of Industrial Circulation Heaters in 2026

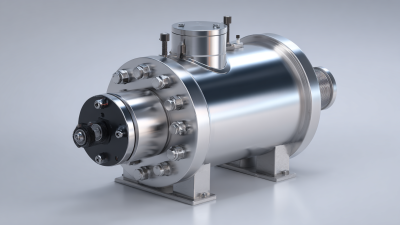

In 2026, industrial circulation heaters are poised for significant advancements. These heaters play a vital role in various manufacturing processes. They ensure precise temperature control for materials needing heating. We can expect improved efficiency and energy consumption in these devices. New technologies could lead to faster heating times and enhanced durability.

The design of industrial circulation heaters in 2026 may shift toward user-centric features. Advanced digital interfaces will likely offer better monitoring. This could help reduce errors during operation. However, the transition to these new technologies may not be seamless. Training staff to use new controls could present challenges. Additionally, adapting existing systems might require troubleshooting and adjustments.

Expect a wider range of materials and applications for circulation heaters. Industries like food processing and chemical manufacturing may see increased options. Yet, the shift toward innovative designs necessitates careful scrutiny. Understanding operational limits is crucial to avoid overloading systems. Each advancement comes with its setbacks, prompting a need for ongoing evaluation.

2026 Top Industrial Circulation Heaters What to Expect?

| Feature | Expected Development in 2026 | Efficiency Rating | Common Applications |

|---|---|---|---|

| Energy Source | Increased use of renewable energy sources | Up to 95% efficiency | Chemical processing, food production |

| Control Systems | Enhanced IoT integration for remote monitoring | N/A | HVAC, Manufacturing |

| Material Advancements | Utilization of advanced composites for better heat retention | N/A | Pharmaceuticals, Plastics |

| Safety Features | Advanced safety mechanisms to prevent overheating | N/A | Oil and Gas, Water Treatment |

| Size and Portability | More compact designs for ease of installation | N/A | Construction, Agriculture |

Key Features to Look for in 2026 Models of Circulation Heaters

As we look forward to 2026, the evolution of circulation heaters will be fascinating. Focus on energy efficiency. Many models will utilize advanced materials that retain heat better. This will lead to lower energy consumption and reduced costs. Manufacturers are experimenting with innovative designs. They aim to improve overall performance while minimizing space requirements.

Temperature control is another vital feature. Expect heaters with precise digital controls. This will allow for better adjustment of heat settings. Enhanced safety features are crucial too. Overheating protection and automatic shut-off are becoming standard. These features will help prevent accidents and ensure longer unit life.

Aesthetics may not seem critical, but looks matter. Sleek designs will make heaters more appealing. Size and portability will also be important. Many users prefer compact units that are easy to move. But can smaller models deliver the same heat output? It's an ongoing challenge. Balancing design with functionality requires reflection and improvement.

Emerging Technologies Influencing Circulation Heaters in 2026

The landscape of industrial circulation heaters is evolving rapidly. Emerging technologies are reshaping efficiency and performance. According to a recent market research report, the global circulation heater market is projected to grow at a compound annual growth rate of 5.7% by 2026. This significant growth indicates a shift toward innovative solutions.

One notable trend is the integration of IoT technology. Smart circulation heaters are becoming intuitive systems. These devices allow for remote monitoring and control, enhancing operational efficiency. Data analytics will be crucial in identifying energy-saving opportunities. However, there are challenges too. The initial investment in these technologies can be substantial, and businesses must weigh the long-term benefits against upfront costs.

Another area of focus is energy efficiency. As regulations tighten, manufacturers are under pressure to produce heaters that meet stricter energy standards. The latest designs often focus on sustainable materials and improved thermal performance. Yet, achieving these standards can require complex engineering and may lead to increased production times. Balancing innovation with practicality remains a critical issue for the industry.

Market Trends Impacting the Industrial Circulation Heater Sector

The industrial circulation heater sector is witnessing significant changes. Market trends are shaping how these systems develop and operate. Energy efficiency remains a pressing concern. Many industries now prioritize sustainable practices. They are looking for heaters that consume less energy and have a smaller carbon footprint.

Smart technology is also making waves. Many plants are embracing IoT for better monitoring. This allows operators to optimize heating processes in real-time. Predictive maintenance can reduce downtime. Yet, challenges remain. Not all facilities can afford such high-tech upgrades. Smaller companies may struggle to implement these advancements.

Regulatory changes could impact future designs. Safety standards are becoming stricter. Heaters must meet new compliance requirements. It forces manufacturers to rethink their approaches. The push for environmental sustainability is both a boon and a burden. It's essential to balance innovation with cost-effectiveness. The future remains uncertain, but the direction is clear—adaptation is key.

Energy Efficiency Standards for Circulation Heaters in 2026

As we approach 2026, energy efficiency standards for circulation heaters are becoming more stringent. The focus is on reducing energy consumption while maintaining performance. According to a recent report by the International Energy Agency, improving heater efficiency by just 10% can lead to significant energy savings. Many industries are being encouraged to adopt heaters with higher efficiency ratings.

New regulations are expected to require a minimum efficiency of 85% for circulation heaters. This shift can significantly impact operational costs. Industries that fail to adapt may face higher energy bills and emissions penalties. Data from the U.S. Department of Energy suggests that non-compliance could cost businesses thousands annually.

In addition, improving insulation and optimizing heater location are also vital. Simple changes can greatly enhance overall system efficiency. However, many companies overlook these critical factors. They focus solely on equipment upgrades. This narrow view may hinder their potential savings and environmental impact.

Safety Features to Expect in New Circulation Heater Designs

As the demand for industrial circulation heaters grows, safety features will take center stage in emerging designs. Robust overheat protection systems will become fundamental. They will prevent potential hazards, ensuring equipment reliability. Consider improved temperature sensors that offer real-time monitoring. These sensors can alert operators to fluctuations, allowing for immediate corrective actions.

Another key focus will be ergonomic designs that enhance usability. Easy-to-read displays and accessible controls may seem minor. However, they can make a significant difference in emergency situations. Situational awareness is critical. A well-placed emergency shutoff switch can save lives.

The shift towards sustainable materials will also be notable. Using eco-friendly components is a commendable goal. Yet, challenges remain in balancing durability and environmental impact. Manufacturers will need to reflect on their choices. These considerations will shape the future of circulation heaters in ways we must anticipate.

Predicted Major Manufacturers and Their Innovations in 2026

As we look ahead to 2026, the industrial circulation heater market is poised for significant advancements. Analysts predict that several major manufacturers will focus on enhancing energy efficiency. A recent report highlighted that industry leaders are expected to increase the thermal efficiency of their units by as much as 25%. This would not only reduce operational costs but also promote sustainability.

Innovations are likely to center around smart technology integration. Systems that utilize IoT will allow for real-time monitoring and improved control of heating processes. According to a study, about 35% of manufacturers are investing in remote diagnostics features. This is seen as a pivotal move toward predictive maintenance, potentially reducing downtime significantly.

However, there are challenges ahead. The reliance on advanced materials for better thermal conduction may lead to supply chain issues. Industry experts express concerns that not all manufacturers can adapt quickly. The need for training technicians to handle smart technologies adds another layer of complexity. As the industry evolves, the balance between innovation and practicality will be critical.

2026 Top Industrial Circulation Heaters: Predictions and Insights

This chart illustrates the predicted market share distribution of industrial circulation heaters in 2026, focusing on various innovative features that are expected to gain traction in the industry. The data showcased reflects anticipated advancements in efficiency, smart technology integration, and eco-friendliness.

Optimal Solutions for Heating Air Ducts: Exploring the Benefits of Tubular Heaters

When it comes to optimizing air duct heating systems, finned tubular heaters stand out as a superior choice. These innovative heating elements are designed with continuous spiral fins brazed to the sheath, significantly enhancing their efficiency. With approximately 4-5 fins per inch, the increased surface area allows for greater heat transfer to the surrounding air. This not only results in faster heating but also helps maintain lower surface element temperatures, reducing the risk of overheating and ensuring a safe operational environment.

The construction of finned tubular heaters plays a crucial role in their effectiveness. By enhancing the interaction between the heating element and the air flowing through the ducts, they provide a more uniform distribution of heat. This efficiency translates into improved energy usage, helping facilities reduce heating costs while still achieving desired thermal comfort levels.

Moreover, the durability of these components, thanks to their robust design and materials, ensures long-lasting performance and minimal maintenance requirements. This reliability is essential for any heating system, as it contributes to ongoing operational stability and efficiency. Ultimately, investing in finned tubular air heating elements presents a practical solution for maximizing heating performance in air duct systems.

FAQS

: Self-reflection helps you understand your thoughts and feelings better. It can improve personal growth and decision-making.

Regular self-reflection is beneficial. Aim for a few times a week. Daily can be too much for some people.

Journaling and meditation are popular methods. You can also talk with trusted friends or mentors.

Yes, it can bring up uncomfortable emotions. It’s important to confront these feelings and learn from them.

Create a quiet space and limit distractions. Set a time limit to keep your mind from wandering.

It’s normal to struggle. Start small and gradually increase your reflection time. Be patient with yourself.

It helps you understand your behavior. This understanding can lead to better communication and stronger connections.

Sharing can be helpful or harmful. Consider the context and your comfort level before sharing deeply personal insights.

Conclusion

The article titled "2026 Top Industrial Circulation Heaters What to Expect?" provides a comprehensive overview of the anticipated developments in the industrial circulation heater sector by 2026. It highlights key features that users should look for in new models, including enhanced energy efficiency and advanced safety measures. Emerging technologies are transforming these heaters, integrating smart controls and improved materials to optimize performance.

Additionally, the article discusses significant market trends that will shape the industry, as well as the evolving energy efficiency standards that manufacturers will need to meet. The insights also cover predicted innovations from leading manufacturers, suggesting a future where industrial circulation heaters become even more reliable and effective for industrial applications. Overall, 2026 is poised to be a pivotal year for advancements in industrial circulation heaters.

Related Posts

-

Top 10 Industrial Circulation Heaters: Best Picks for Optimal Heating Solutions

-

Unlocking Efficiency: The Benefits of Customized Industrial Heaters for Your Business

-

The Ultimate Guide to Choosing the Best Industrial Flange Heater Suppliers for Your Needs

-

Top 10 Tips for Choosing the Best Industrial Heater Bundle in China

-

How to Choose the Best Customized Industrial Heater for Your Needs

-

How to Optimize Your Industrial Heater Bundle Pricing for Maximum Efficiency and Cost Savings

Blog Tags: