Advantages of Choosing Customized Industrial Heater Manufacturers for Your Business Needs

Table of Contents

- Benefits of Tailoring Industrial Heaters to Your Specific Processes

- How Customized Solutions Enhance Efficiency and Performance

- Comparative Costs: Off-the-Shelf vs. Customized Industrial Heaters

- The Role of Specialized Support from Custom Heater Manufacturers

- Ensuring Safety and Compliance with Bespoke Heating Solutions

- Case Studies: Successful Upgrades with Customized Heaters in Industry

- The Ultimate Guide to Customized Industrial Immersion Heaters: Tailoring Solutions for Optimal Efficiency

- FAQS

- Conclusion

- Related Posts

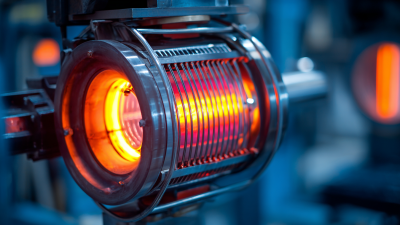

In today’s fast-moving industrial world, more and more businesses are realizing just how important it is to have solutions that are tailored specifically for their unique needs. Industry reports suggest that the global market for industrial heaters is expected to hit around $15 billion by 2026 — and a big chunk of that growth is fueled by the rising demand for heating options that are both efficient and customized. When choosing a manufacturer for industrial heaters, going for one that offers personalized solutions can really make a difference. It helps companies boost energy efficiency, keep operations running smoothly, and improve safety overall.

Take Jiangsu Weineng Electric Co., Ltd., for example. They’re a high-tech enterprise with a solid reputation, specializing in explosion-proof electric heaters. They've got extensive experience in designing, manufacturing, and commissioning their products. Partnering with a company like Weineng doesn’t just mean getting access to the latest tech — it also means enjoying a level of service that’s tailored to your specific heating needs. All in all, working with the right manufacturer helps businesses stay competitive and set themselves up for future success in their industry.

Benefits of Tailoring Industrial Heaters to Your Specific Processes

Honestly, in today’s industrial world, there’s never been a time when customizing solutions is more important. Tailoring industrial heaters to fit specific processes isn’t just a nice touch—it can really boost efficiency and cut down costs. I came across a recent review that highlighted just how much potential there is for making use of waste heat better. For example, pinch-based methods show some pretty promising opportunities, especially for district heating setups. When companies tweak their heating systems to match what their operations actually need, they can tap into this potential fully—leading to better productivity and a more sustainable way of doing things.

On top of that, advances in manufacturing tech and new materials—like lightweight composites—are opening up new ways to make these heaters perform even better. Studies suggest that using these super-efficient materials can cut energy use and improve thermal performance, which is right in line with the global push toward more circular, eco-friendly models. More and more, custom manufacturers are stepping up with solutions that are built just for specific needs, making sure each system does its best while being kind to the environment. This kind of tailor-made approach doesn’t just make operations more reliable; it also sparks innovation, which is so vital if businesses want to stay competitive these days.

Advantages of Choosing Customized Industrial Heater Manufacturers for Your Business Needs

| Advantage | Description | Impact on Business | Examples of Application |

|---|---|---|---|

| Enhanced Efficiency | Customized designs optimize energy use and heat distribution. | Lower operating costs and improved process output. | Food processing, chemical production. |

| Increased Reliability | Tailored heaters reduce breakdowns and maintenance needs. | Minimized downtime and consistent production levels. | Plastic molding, metalworking. |

| Flexibility in Design | Heaters can be designed to fit specific space and application requirements. | Improved integration into existing systems. | Textile drying, semiconductor manufacturing. |

| Customization to Process Needs | Heaters designed for specific temperature ranges and control features. | Enhanced quality control and product consistency. | Pharmaceuticals, food safety. |

| Improved Safety | Custom safety features can be integrated to match workplace standards. | Decreased risk of accidents and liability issues. | Chemicals, renewable energy installations. |

| Better Service and Support | Working with manufacturers ensures tailored support and training. | Quicker response to problems, leading to efficient operations. | Customized maintenance programs for unique systems. |

How Customized Solutions Enhance Efficiency and Performance

Customized industrial heaters really make a difference when it comes to boosting efficiency and performance across different sectors. You know, a recent report from the International Energy Agency mentioned that roughly 20% of the world's energy goes into industrial heating, and a big chunk of that just gets wasted because the heating systems aren’t optimized. That’s why more businesses are turning to tailored heating solutions — they can cut energy costs quite a bit. In fact, some studies suggest you could save up to 30% when switching from standard to custom-made systems.

And it’s not just about saving energy. These personalized heaters are designed to meet the specific needs of different processes, which really helps improve product quality and keeps things consistent. I came across a survey from ASHRAE, and it said that companies using customized heating setups saw about a 25% boost in productivity compared to those sticking with regular equipment. That’s probably because these systems give you better temperature control and respond faster, letting manufacturers hit precise temperatures that fit their unique processes. In the end, this means less downtime and more efficient output — pretty cool, right?

Comparative Costs: Off-the-Shelf vs. Customized Industrial Heaters

When you're looking into industrial heaters for your business, it’s really important to weigh the costs of ready-made solutions versus custom-built ones. I came across a report from the Industrial Heating Equipment Association (IHEA) that sheds some light on this. Basically, while off-the-shelf heaters might seem cheaper at first glance, they often end up costing more in the long run because they tend to be less efficient and might not fit the specific needs of your setup. For example, these generic heaters could use 20-30% more energy than a custom solution, which adds up and can really take a toll on your budget and sustainability efforts.

On the flip side, going for a customized industrial heater might mean shelling out 10-25% more initially compared to standard models. But here’s the kicker: according to a study by Research and Markets, companies that go the custom route usually see an impressive ROI of around 150%. That’s mainly because these tailored systems are more energy-efficient and cut down on maintenance costs. Plus, they can actually boost process productivity — no more downtime, better temperature control — making them a pretty compelling choice if you’re in a competitive industry and want real value in the long run.

The Role of Specialized Support from Custom Heater Manufacturers

When you're on the hunt for efficient heating solutions for your business, teaming up with custom industrial heater makers can really give you some solid perks. One big advantage? The personalized support they offer. These folks get that every industry has its own heating quirks, so they can design solutions that fit your specific needs like a glove. And because they know their stuff, you'll get heaters that not only work really well but also mesh smoothly with your current systems.

**Tip:** When you're picking a custom heater manufacturer, go for companies that are big on consultations. Chatting things out early on can help make sure that the final product checks all your technical boxes and fits your operational needs.

Plus, part of that specialized support means ongoing maintenance and troubleshooting — super important for avoiding those annoying downtimes. Many custom heater providers offer full-service agreements, so you can count on your systems staying up and running smoothly. They’re quick to jump in if something goes wrong and can tweak their solutions on the fly, which is a real lifesaver in fast-moving industrial settings.

**Tip:** It’s also worth considering manufacturers who offer training for your team on how to handle the new systems. Investing a little in training can pay off big-time, helping your people use and maintain everything better, and that can boost everyone’s productivity in the long run.

Ensuring Safety and Compliance with Bespoke Heating Solutions

When it comes to industrial heating solutions, safety and compliance? They're pretty much non-negotiable. That’s where custom industrial heater manufacturers come into play — crafting tailored solutions that fit your specific needs while still ticking all the boxes laid out by industry standards. I came across a report from the International Electrotechnical Commission (IEC) that said nearly 30% of industrial accidents are caused by unsafe heating practices. That’s a pretty staggering number! So, customizing heaters to meet safety regulations isn’t just a good idea — it’s kinda essential. It can really help cut down those risks and give you some peace of mind, knowing your team is safer.

And here’s the cool part — these custom heaters often come packed with the latest tech. That means they’re not just about safety; they also help companies stay on top of environmental standards. A study from the U.S. Environmental Protection Agency (EPA) showed that industries using customized heating solutions can be up to 25% more energy-efficient than the standard, off-the-shelf options. That’s a big deal because it helps save money on energy bills and supports eco-friendly goals at the same time. Basically, investing in a custom heating solution isn’t just about getting the job done — it’s about creating a safer, more compliant workspace where everyone can focus on what they do best. It’s a win-win, really, for sustainability and safety overall.

Case Studies: Successful Upgrades with Customized Heaters in Industry

When it comes to upgrading industrial heating setups, more and more businesses are realizing just how much they can benefit from working with manufacturers who make custom industrial heaters. If you take a closer look at some real-world cases, you'll see that these tailored heating systems do more than just boost energy efficiency—they also help optimize performance specifically in each company's unique working environment. For example, industries that have gone with personalized environmental control systems (PECS) often report pretty noticeable drops in energy use. This really shows how customizing the setup can directly address their specific heating, cooling, and ventilation needs.

**Tip:** Before you pick a manufacturer, take some time to really understand what your facility needs. Making sure the heaters are custom-fit to your operations can make a huge difference. Also, working closely with the manufacturer during the design process can lead to some pretty innovative solutions—saving energy and money in the long run.

In a study focusing on energy performance, they used a structured framework for PECS that helps companies see how well their heating systems are actually working. This kind of framework makes it easier to decide when and how to upgrade or tweak systems, which can cut down operating costs and lessen environmental impact.

**Tip:** Keep regularly checking how your heating systems perform against this framework. It can give you good insights on when to consider upgrades and help plan your future investments for better efficiency. Remember, custom solutions aren’t just about fitting a product to a need—they’re about committing to long-term sustainability and top-notch performance.

The Ultimate Guide to Customized Industrial Immersion Heaters: Tailoring Solutions for Optimal Efficiency

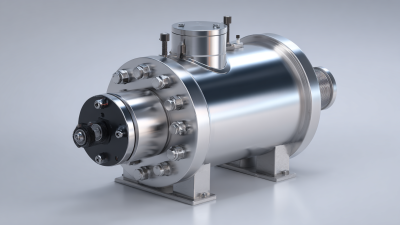

When it comes to industrial processes, selecting the right immersion heater can greatly influence the efficiency and performance of your operations. The customization of these heaters is crucial, as different applications require specific designs to meet their unique demands. According to a report by the International Energy Agency, optimizing heating processes can lead to energy savings of up to 30%, demonstrating the importance of tailored heating solutions.

WNH specializes in custom-manufactured immersion heaters that are built around the specific needs of your industrial processes. Understanding that one size does not fit all, our team collaborates closely with clients to establish the most effective heater configurations. We evaluate factors such as required wattage, optimal materials, and suitable heater types to tailor solutions that enhance efficiency, improve lifespan, and maximize overall effectiveness. This approach not only ensures that heating requirements are met but also aligns with budgetary considerations, making it a prudent investment for manufacturers.

Moreover, with an increasing focus on sustainability and energy efficiency, selecting the right immersion heater is becoming paramount. Research indicates that the industrial sector accounts for significant energy consumption, and adopting customized heating solutions can play a vital role in reducing carbon footprints. By leveraging our expertise, organizations can implement immersion heaters that not only meet operational requirements but also contribute positively to environmental goals.

FAQS

: Customizing industrial heaters can lead to significant efficiency gains, cost reductions, improved thermal efficiency, and enhanced performance tailored to specific processes.

Studies have indicated that businesses can achieve energy savings of up to 30% when replacing conventional systems with customized heating solutions.

Customized industrial heaters can improve product quality and consistency due to better temperature control and faster response times that adapt to unique processes.

While customized heaters may require a higher initial investment (10-25% more), they provide significant long-term savings and greater energy efficiency compared to off-the-shelf heaters.

Companies using customized heating solutions reported a 25% increase in productivity, attributed to enhanced temperature control and reduced downtime.

Using advanced materials can improve thermal efficiency and reduce energy consumption, aligning with trends toward circular economic models.

Research indicates that companies utilizing customized heaters report an average ROI of 150% due to improved efficiency and reduced maintenance costs.

Off-the-shelf heaters can consume 20-30% more energy than tailored options, leading to higher operational costs and undermining overall budget sustainability.

Customized solutions strengthen operational reliability by minimizing downtime and optimizing heating processes to meet specific operational needs.

They foster innovation and adaptability by ensuring that heating systems perform to their fullest potential while minimizing environmental impact.

Conclusion

When you’re looking to optimize your heating setup, choosing custom industrial heater manufacturers can really make a difference. Instead of settling for generic, one-size-fits-all heaters, getting equipment tailored to your specific processes ensures everything runs smoothly—better efficiency, improved performance, and all that good stuff. Plus, in the long run, custom solutions can actually save you money by cutting down on energy waste and giving you higher quality output.

And here’s the thing—partnering with specialized manufacturers like Jiangsu Weineng Electric Co., Ltd. really helps when it comes to installing and getting your heating systems up and running. They make sure everything’s safe, follows industry standards, and bring a ton of expertise to the table. There are plenty of success stories across different industries showing how these upgrades can really pay off. Looking into customized heating options isn’t just about fixing the present—it’s also a smart move for future growth and staying ahead of the game.

So, all in all, investing in tailored heating solutions isn’t just about immediate benefits—it's about setting your business up for long-term success and innovation.

Related Posts

-

Emerging Technologies for Industrial Flange Heater Solutions by 2025

-

Essential Checklist for Obtaining the Best Industrial Heater Bundle Quotes

-

Evaluating the Best Customized Industrial Heater Suppliers: A Comprehensive Comparison Guide

-

The Ultimate Guide to Choosing the Best Industrial Flange Heater Suppliers for Your Needs

-

Challenges Faced by Industrial Heating Bundle Factories in Modern Manufacturing

-

Ultimate Checklist for Sourcing Best China Industrial Heater Bundles in 2023

Blog Tags: