Challenges Faced by Industrial Heating Bundle Factories in Modern Manufacturing

Table of Contents

- Understanding the Unique Needs of Industrial Heating Bundle Factories

- Key Challenges in Material Sourcing and Supply Chain Management

- Technological Advancements and Their Impact on Production Efficiency

- Workforce Skills Gap: Training and Retention in Modern Manufacturing

- Adapting to Sustainability Regulations in Industrial Heating Production

- Navigating Cost Pressures and Competitive Pricing in the Industry

- FAQS

- Conclusion

- Related Posts

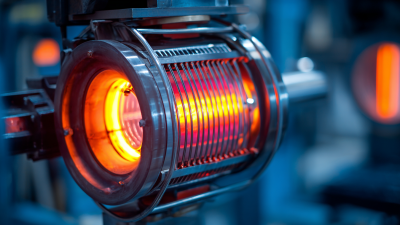

In today's fast-changing world of manufacturing, Industrial Heating Bundle Factories face a lot of challenges that can really hold back their growth and efficiency. These factories are super important because they provide reliable heating solutions, but they also have to deal with stuff like strict regulations, new tech coming out all the time, and markets that are constantly shifting. Jiangsu Weineng Electric Co., Ltd. is right there at the cutting edge of this industry. They're a high-tech company specializing in explosion-proof electric heaters, and they've got tons of experience in design, production, and getting everything up and running. Weineng truly gets the hurdles that these factories face and is always working on innovative solutions — not just to meet industry standards, but to help improve overall operations. As we look closer at these issues, it’s clear that tackling them is key if these factories want to stay competitive and succeed in this ever-changing manufacturing scene.

Understanding the Unique Needs of Industrial Heating Bundle Factories

Industrial heating bundle factories are pretty important in today’s manufacturing world, but they face some pretty unique challenges because of the specific needs of their operations. These factories are responsible for creating heating bundles that are not just efficient but also durable—tailored to industries like energy, automotive, and HVAC. That kind of specialization means they need a solid grasp of materials, thermal physics, and manufacturing processes. Unfortunately, this can get tricky if they’re stuck using outdated machines or sticking to business models that don’t adapt well to change.

On top of that, there’s a growing push for energy-efficient solutions, so these factories need to be quick on their feet when it comes to innovation. They don’t just have to meet all the rules and standards—they also need to actively find ways to be more sustainable in their production. That usually means big investments in R&D and training workers so they’re up-to-date on new tech and materials. Keeping everything aligned—technology, efficiency, innovation—can be a real juggling act. The constant pressure to stay productive while also pushing for progress makes it a tough but necessary balancing act.

Challenges Faced by Industrial Heating Bundle Factories

This chart illustrates the various challenges faced by industrial heating bundle factories in modern manufacturing, including supply chain issues, technological advancements, workforce shortages, and compliance with regulations.

Key Challenges in Material Sourcing and Supply Chain Management

You know, the modern world of manufacturing is pretty challenging these days, especially for factories that make heating bundles. One of the biggest headaches right now is getting the materials you need and dealing with supply chain hiccups. According to a report from the National Association of Manufacturers, disruptions in supply chains have gone up by about 50% since the pandemic hit. That’s caused real delays in sourcing the critical materials essential for production, which ends up hurting the efficiency and overall output of these heating bundle factories.

On top of that, finding reliable sources for materials isn’t a walk in the park. Many factories are finding it tough to get the components they need at stable prices. Take the global steel shortage, for instance—prices have skyrocketed by as much as 200% in some markets, according to the World Steel Association. Because a lot of these manufacturers depend on specific types of steel, they’re now having to consider alternative materials or seek out different suppliers—something that’s often time-consuming and can cost more. Plus, constant changes in international trade policies and tariffs just spice things up, making it even trickier to plan ahead. In this competitive industry, being flexible and staying ahead of the game really becomes a must.

Technological Advancements and Their Impact on Production Efficiency

You know, in today’s manufacturing world, factories like Jiangsu Weineng Electric Co., Ltd. that focus on industrial heating face some pretty big hurdles when it comes to weaving new tech into their everyday processes. We’re talking about the value of applying AI, advanced computing, and automation — it’s really a game-changer. These tools can seriously boost how efficiently and high-quality the production lines are running. For example, AI algorithms can fine-tune heating procedures so that energy use drops, but the end product still meets all safety and quality standards. Pretty cool, right?

Here's a little tip — investing in AI-powered analytics can really help spot bottlenecks in your production line before they become major issues. Taking that proactive approach can make a big difference in smoothing out operations and giving your overall efficiency a boost.

And I think it’s also super important to mention the whole push toward a greener economy. Companies are now looking for ways to adopt more sustainable manufacturing practices. Using advanced tech isn’t just about being more efficient — it’s about doing good for the environment too. Tasks like material handling and quality checks, when automated, help cut down on waste and reduce carbon footprints. Win-win, right?

Here’s another tip — consider teaming up with R&D partners to develop eco-friendly production methods. Working together on innovative solutions can help you hit your targets for both productivity and sustainability at the same time.

Workforce Skills Gap: Training and Retention in Modern Manufacturing

In today's fast-paced world of manufacturing, factory workers dealing with industrial heating bundles are facing a pretty big challenge: the skills gap. As technology speeds along faster than ever, there's a big jump in the need for skilled folks who can run all the fancy new machinery and understand complex processes. Unfortunately, a lot of workers just don’t have the training for it, which creates this gap between what the industry needs and what workers can actually do. That’s not just holding back productivity, it can also put manufacturers at a disadvantage in the global marketplace.

Fixing this skills gap isn’t something you can just do overnight — it needs a mix of approaches. For starters, training programs need to be tailored to really give workers the technical know-how they need to keep up with changes. Investing in ongoing education and apprenticeship programs can go a long way toward closing that divide and helping folks develop new skills. And let’s not forget about keeping employees happy and engaged — offering career growth opportunities, making sure they feel valued, and creating a supportive work environment can really help build loyalty. When factories focus on these things, they end up with a dedicated, skilled team that’s ready to tackle what modern manufacturing throws at them.

In the end, it’s all about adapting and investing in people — because that’s how you stay competitive in this fast-moving industry.

Adapting to Sustainability Regulations in Industrial Heating Production

The industrial heating industry is really facing some pretty big hurdles right now, especially as manufacturers try to keep up with all these new sustainability rules. Honestly, the push for greener practices is changing how things are done — factories are feeling the pressure to switch over to eco-friendly tech and methods. With new policies aimed at cutting emissions and boosting energy efficiency, heating plants need to act fast if they want to stay compliant. This isn't just about swapping out old gear; it’s about really getting to know new technologies like industrial heat pumps, which everyone seems to think will explode in popularity over the next decade.

The industrial heating industry is really facing some pretty big hurdles right now, especially as manufacturers try to keep up with all these new sustainability rules. Honestly, the push for greener practices is changing how things are done — factories are feeling the pressure to switch over to eco-friendly tech and methods. With new policies aimed at cutting emissions and boosting energy efficiency, heating plants need to act fast if they want to stay compliant. This isn't just about swapping out old gear; it’s about really getting to know new technologies like industrial heat pumps, which everyone seems to think will explode in popularity over the next decade.

A good tip? Investing in training your team on sustainability stuff can really make a difference — it boosts both compliance and sparks innovation. Also, working with suppliers who care about sustainability can make the whole transition a lot smoother.

As companies scramble to meet these changing rules, they should also think about the financial side of things. Markets for HVAC equipment and electric heating are expected to grow a ton, mainly because people are more interested in cleaner energy options. So, factories really need to align their strategies to tap into these trends. That way, they can stay competitive and tick all the boxes on regulations.

Another thing? It’s a smart move to regularly review and tweak your operations to include sustainable practices — it can save you money in the long run. And keeping an eye on industry trends can help your business stay ahead of the game, especially with things changing so fast.

Navigating Cost Pressures and Competitive Pricing in the Industry

In today’s really competitive manufacturing world, factories that produce industrial heating bundles are feeling the squeeze of rising costs, which is making it tough to keep things running smoothly. Costs for raw materials are climbing, and energy prices keep bouncing around, pushing these factories into tricky territory. Because of that, they have to get creative—looking for new materials or smarter ways to manufacture stuff so they can keep making a profit without sacrificing quality.

On top of that, trying to stay competitive with price tags makes everything even more complicated. With so many companies out there fighting for the same customers, factories often have to cut prices just to stay afloat, which can really cut into their margins. To handle this, many are putting money into new tech and automation—stuff that helps speed things up and cut labor costs. Not only does this make operations more efficient, but it also helps keep the quality high. That way, they can stay sharp in pricing and still deliver good products.

At the end of the day, it’s all about finding that sweet spot—balancing innovation, tight cost control, and smart pricing strategies. If they get it right, they can survive and even succeed in this really demanding market.

FAQS

: Heating bundle manufacturers face challenges such as significant price hikes for critical materials, specifically due to global steel shortages, and reliance on specific grades of steel which are increasingly scarce.

Supply chain disruptions have increased by 50% since the onset of the pandemic, leading to delays in sourcing critical materials needed for production.

Fluctuations in international trade policies and tariffs complicate procurement strategies, making it essential for manufacturers to maintain agility and foresight.

The workforce skills gap refers to the lack of specialized training among current workers, who are unable to effectively operate advanced machinery and adapt to new processes required in modern manufacturing.

Strategies include tailored training programs, continuous education, apprenticeships, and promoting career growth and job satisfaction to enhance employee retention.

Retention is crucial as a loyal and skilled workforce is essential for maintaining productivity and competitive advantage in the fast-evolving manufacturing landscape.

Training programs can provide workers with the necessary technical skills and knowledge required to adapt to rapidly changing manufacturing environments, bridging the gap between industry needs and employee capabilities.

Employee satisfaction is important for retention; creating a supportive workplace environment and promoting career growth can lead to a more capable and dedicated workforce.

The demand for skilled labor has surged due to rapid technological advancements, leading to a greater need for workers who can operate advanced machinery and understand new manufacturing processes.

Investment in training programs, alternative materials, and suppliers, as well as employee retention strategies, is crucial for overcoming challenges in material sourcing and closing the skills gap.

Conclusion

Industrial Heating Bundle Factories are really facing quite a few hurdles these days in the fast-moving world of manufacturing. For one, juggling the whole material sourcing and supply chain can get pretty complicated — and if those aren’t managed well, it can throw a wrench in production. Plus, with tech constantly evolving, factories have to stay on their toes; sometimes these advancements boost efficiency, but other times they can complicate workflows, making it a constant game of catch-up. Then there’s the talent gap — finding qualified workers and keeping them around isn’t easy, especially with the skills needed changing all the time. It’s a real challenge to train people and make sure there’s always skilled staff ready to handle the bigger demands.

Beyond all that, these factories also need to juggle new sustainability rules that can affect how they operate. Add to that the pressure to keep costs low because of fierce market competition — it’s a lot to handle all at once. Companies like Jiangsu Weineng Electric Co., Ltd., who are experts in making explosion-proof electric heaters, really show what it takes to overcome all these hurdles while still staying compliant and running efficiently. It’s definitely no walk in the park, but they’re doing their best to keep up and succeed.

Related Posts

-

Emerging Technologies for Industrial Flange Heater Solutions by 2025

-

Exploring Innovative Alternatives: The Future of the Best Electric Process Heater for Global Buyers

-

Evaluating the Best Customized Industrial Heater Suppliers: A Comprehensive Comparison Guide

-

Exploring Unique Features of Industrial Heating Bundles and How to Select the Best Supplier

-

Premium Electric Heater Solutions from China Your Trusted Global Manufacturing Partner

-

Essential Checklist for Obtaining the Best Industrial Heater Bundle Quotes

Blog Tags: