Innovative Solutions for China Industrial Heater Bundle Efficiency and Reliability

Table of Contents

- Innovative Trends in Industrial Heater Bundles for Enhanced Efficiency

- Key Technologies Driving Reliability in China’s Heating Industry

- Comparative Analysis of Energy Consumption in Various Heater Designs

- Impact of Advanced Insulation Materials on Heater Bundle Performance

- Cost-Benefit Analysis: Traditional vs. High-Efficiency Heater Bundles

- Industry Standards and Regulations Influencing Heater Efficiency in China

- FAQS

- Conclusion

- Related Posts

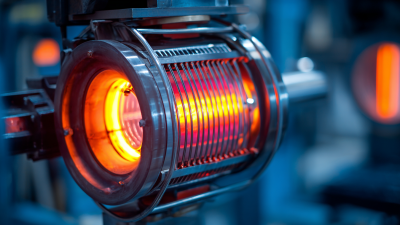

As the demand for reliable and energy-efficient heating solutions keeps climbing across different industrial sectors, it's pretty clear that optimizing China's industrial heater bundles is more important than ever. A report from ResearchAndMarkets suggests that this market is set to see some serious growth, mainly because industries are increasingly on the lookout for smarter, more energy-saving heating options for their manufacturing processes. Jiangsu Weineng Electric Co., Ltd. is really leading the charge in this area. They’re using their expertise in making explosion-proof electric heaters to improve the efficiency of these bundles, all while making sure safety and reliability are top priorities. With years of experience in designing, producing, and commissioning these systems, Weineng really is dedicated to offering innovative solutions that fit their customers’ specific needs. And as more stakeholders start requesting quotes for China industrial heater bundles, it’s super important to focus on advancements that deliver both performance and sustainability in this space.

Innovative Trends in Industrial Heater Bundles for Enhanced Efficiency

When it comes to industrial heating solutions, two things really matter—efficiency and reliability. Lately, there've been some pretty exciting advancements in heater bundles, thanks to new materials and tech that boost performance while also cutting down on energy use. One of the coolest trends I've seen is the use of nanotechnology. Basically, it lets engineers work with materials at an incredibly tiny level, which means hot stuff like thermal conductance and durability are getting a serious upgrade. So, these heaters last longer and can handle way tougher conditions than before.

On top of that, people are reinventing the classic heat exchangers with some innovative twists. Think twisted tubes and surfaces coated with graphene—that’s some next-level stuff. These tweaks make heat transfer more efficient, which means the heaters use less energy overall. Plus, it’s a win for sustainability because industries can keep up their productivity without harming the environment too much. All in all, these ongoing improvements in heater bundles are set to shake things up across many sectors, bringing a new era of really reliable, efficient industrial heating.

Key Technologies Driving Reliability in China’s Heating Industry

The heating industry in China is really going through some big changes these days. Thanks to new and innovative tech, things are becoming more efficient and reliable than ever before. One of the biggest game-changers is smart control systems that use IoT (Internet of Things) tech — basically, they can monitor and fine-tune heater performance in real-time, which is pretty cool. I read in a report by ResearchAndMarkets that the smart heating market in China is expected to grow around 15% annually from 2021 to 2026. That’s a pretty clear sign that more and more companies are jumping on board with these tech solutions, especially in industrial settings.

The heating industry in China is really going through some big changes these days. Thanks to new and innovative tech, things are becoming more efficient and reliable than ever before. One of the biggest game-changers is smart control systems that use IoT (Internet of Things) tech — basically, they can monitor and fine-tune heater performance in real-time, which is pretty cool. I read in a report by ResearchAndMarkets that the smart heating market in China is expected to grow around 15% annually from 2021 to 2026. That’s a pretty clear sign that more and more companies are jumping on board with these tech solutions, especially in industrial settings.

And it’s not just about smart controls. There’s also some really exciting stuff happening with materials. Engineers are now using high-performance ceramics and composite materials to make heaters that are way tougher and can handle extreme conditions. According to the Global Heating Equipment Market report, the demand for these durable industrial heaters is expected to skyrocket, with the market hitting over USD 50 billion by 2025. These innovations don’t just make equipment last longer—they also cut down maintenance costs, which is a huge win for industries trying to keep things running smoothly.

Plus, improvements in energy management systems are playing a key role, too. These systems help with predicting maintenance needs and forecasting usage, reducing downtime, and making operations more reliable overall. The Chinese National Development and Reform Commission even estimates that boosting energy efficiency by 20% in the heating sector could save about USD 12 billion every year. So, it’s clear: reliable, cutting-edge heating tech isn’t just good for business—it’s a financial win, too.

Comparative Analysis of Energy Consumption in Various Heater Designs

Lately, you know, the industrial scene in China has really been buzzing with new advanced heating options. Companies are keen on improving efficiency and reliability, and when you compare different heater designs, the differences in performance are pretty clear. Old-school heating systems often just don’t cut it when it comes to energy efficiency—they end up costing more to run and cause more environmental harm. On the flip side, newer tech like induction heaters and infrared radiant heaters are kind of game-changers. They save a ton of energy, which is why more and more manufacturers are jumping on board with these newer solutions.

When we look at how these different heaters use energy, it also tells us a lot about how dependable they are in real industrial settings. For example, electric heaters tend to use less energy overall compared to resistance heating units, which seem to waste a lot of heat. Plus, modern heaters now come with smart control tech—stuff that helps better manage energy use, cut down on waste, and make the whole system more reliable. As Chinese industries keep embracing these cutting-edge heating options, they’re not just saving money—they’re also playing a part in making manufacturing more sustainable overall.

Innovative Solutions for China Industrial Heater Bundle Efficiency and Reliability - Comparative Analysis of Energy Consumption in Various Heater Designs

| Heater Design | Power Rating (kW) | Energy Consumption (kWh) | Efficiency (%) | Reliability (MTBF hours) |

|---|---|---|---|---|

| Electric Heater A | 10 | 80 | 90 | 20000 |

| Gas Heater B | 15 | 120 | 85 | 25000 |

| Induction Heater C | 12 | 95 | 92 | 15000 |

| Infrared Heater D | 8 | 60 | 88 | 18000 |

| Convection Heater E | 9 | 70 | 80 | 22000 |

Impact of Advanced Insulation Materials on Heater Bundle Performance

You know, advanced insulation materials really make a huge difference when it comes to boosting how well industrial heater bundles perform. They don’t just help with efficiency—they also play a big role in making the equipment more reliable over time. I came across a recent report from the International Energy Agency, and it mentioned that proper insulation can cut energy losses in heating systems by as much as 80%. That’s a pretty big deal! Not only does this save on energy costs, but it also helps the heaters last longer. When you minimize thermal bridging and make sure heat is evenly distributed, using materials like aerogels or vacuum insulation panels becomes pretty much essential in modern industrial setups.

If you’re thinking about it, investing in high-quality insulation that can handle high temperatures is definitely worth considering. Over the long run, it can save you a lot of money and improve your system’s reliability.

Plus, switching to advanced insulation tech isn’t just good for your wallet—it also helps in meeting the increasingly strict energy efficiency standards popping up around the world. For example, using high-performance insulation can help facilities stay compliant with ISO 50001 energy management standards. So, by focusing on better insulation, industries not only get better heater performance but also contribute to sustainability and reduce their carbon footprint.

A tip on that—regularly check how your existing insulation is holding up. Doing periodic assessments can really boost your heater’s performance and save you headaches down the line.

Cost-Benefit Analysis: Traditional vs. High-Efficiency Heater Bundles

In the world of industrial heating, companies often find themselves at a crossroads: stick with the traditional heater bundles or switch over to those newer, high-efficiency options? According to a recent report from the International Energy Agency (IEA), classic industrial heaters usually run at about 70% to 85% efficiency. That means a good chunk of energy gets wasted, which ends up costing quite a bit in the long run. On the flip side, high-efficiency heater bundles can push efficiency all the way up to 95%. That’s a big difference — think savings of around 30% on energy bills each year for a lot of facilities. It’s pretty clear that investing in more advanced heating tech can really pay off financially.

But it’s not just about saving money. These high-efficiency heaters are also a win for the environment. A study from the U.S. Department of Energy points out that upgrading to these systems can cut greenhouse gas emissions by up to 20%. That’s definitely a step in the right direction, especially for industries trying to lower their carbon footprint. Sure, the initial cost of these high-efficiency setups might be higher, but when you look at the long-term savings and the positive environmental impact, it really makes sense. For industries wanting to improve reliability while also doing the right thing for the planet, these advanced heating options are worth considering.

Energy Efficiency Comparison: Traditional vs. High-Efficiency Heater Bundles

Industry Standards and Regulations Influencing Heater Efficiency in China

Lately, there’s been a real push in China to make industrial heaters more efficient and reliable—thanks to stricter industry standards and regulations. The China Industry Association emphasizes that these heaters should hit at least Level 1 efficiency, which means a minimum of 95%. It’s not just about meeting rules; focusing on high efficiency helps companies save money in the long run and supports global sustainability efforts. Brands like Jiangsu Weineng Electric Co., Ltd. are leading the way, designing explosion-proof electric heaters that tick all these important boxes.

If you want to get the most out of your industrial heater, it’s a good idea to regularly check how it’s performing against current standards. Doing some preventive maintenance can boost efficiency by around 15-20%, based on data from the National Energy Administration. Also, investing in quality insulation can really cut down heat loss, helping you stay compliant while slashing energy costs.

Pro tip: Think about installing real-time monitoring systems. They let you keep an eye on your heater’s performance and make quick adjustments—saving energy before it’s wasted. And don’t forget about regular training for your team, so everyone stays up-to-date on the latest industry rules. Keeping compliance in check and fostering sustainable practices can really make a difference for your business.

FAQS

: High-efficiency heaters can achieve efficiencies of up to 95%, resulting in significant energy savings, with facilities potentially saving an average of 30% on energy costs annually. They also contribute to reduced greenhouse gas emissions by up to 20%, making them environmentally friendly.

Traditional industrial heaters typically operate at an efficiency level of around 70%-85%, which leads to significant energy losses and higher operational costs.

The deployment of control technologies in modern heaters allows for better energy management, reducing waste, enhancing system reliability, and improving overall energy efficiency.

Industrial heaters in China must meet at least Level 1 standards, which require a minimum efficiency of 95%, as mandated by the China Industry Association.

Companies can improve heater efficiency by conducting regular performance assessments, implementing preventive maintenance, investing in quality insulation, and utilizing real-time monitoring systems.

Preventive maintenance can lead to a 15-20% increase in energy efficiency by ensuring heaters operate at optimal performance levels and comply with regulatory standards.

The energy consumption patterns, incorporation of advanced control technologies, and adherence to industry standards contribute to the reliability of various heater designs in industrial applications.

Long-term benefits include substantial cost savings on energy bills, reduced greenhouse gas emissions, and improved compliance with environmental regulations, contributing to a more sustainable operational model.

Adopting innovative heating solutions enhances energy efficiency, reduces operational costs, minimizes environmental impact, and aligns businesses with global sustainability goals.

Regular training for staff on the latest industry regulations and operational best practices can enhance compliance, operational awareness, and ensure sustainable practices are prioritized within the organization.

Conclusion

The heating scene in China is changing fast, and new trends in industrial heater bundles are really making a difference when it comes to efficiency and reliability. You know, things like advanced insulation materials and innovative designs are super important — they help save energy and make the whole system work better. When you compare different heater designs, it becomes pretty clear there’s a big difference in how much energy they use, which is a big deal when you're weighing costs and benefits between traditional options and the newer, high-efficiency ones.

Jiangsu Weineng Electric Co., Ltd. is really leading the way in making explosion-proof electric heaters. Of course, understanding the industry standards and regulations is more than just helpful — it’s actually key to making sure your heater runs at peak performance. They provide these really handy "China Industrial Heater Bundle Quotes" that showcase the latest advances and best practices in the field. Ultimately, it’s all about helping clients get reliable, cost-effective heating solutions that really deliver the goods.

Related Posts

-

The Ultimate Guide to Flange Industrial Heaters: Maximizing Efficiency and Safety in Your Operations

-

The Ultimate Guide to Scr Control for Electric Heaters: Boosting Efficiency with Industry Insights

-

Ultimate Checklist for Sourcing Best China Industrial Heater Bundles in 2023

-

7 Tips to Choose the Right China Explosion Proof Industrial Heater for Your Business

-

Evaluating the Best Customized Industrial Heater Suppliers: A Comprehensive Comparison Guide

-

Challenges Faced by Industrial Heating Bundle Factories in Modern Manufacturing

Blog Tags: