How to Choose the Best Customized Industrial Heater for Your Needs

Table of Contents

- Understanding the Types of Customized Industrial Heaters Available

- Evaluating the Heating Requirements for Your Specific Application

- Key Features to Consider When Selecting an Industrial Heater

- Materials and Construction: Choosing the Right Specifications

- Energy Efficiency and Cost Considerations in Industrial Heaters

- Safety Standards and Compliance for Customized Heating Solutions

- Consulting Experts: When and How to Seek Professional Advice

- FAQS

- Conclusion

- Related Posts

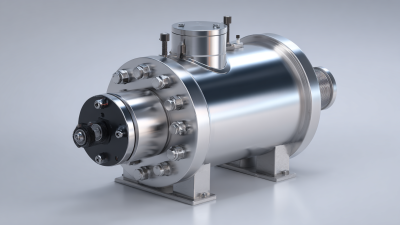

Picking the right customized industrial heater really matters if you want to get the most out of your processes and boost productivity. Honestly, with so many options out there, it can feel overwhelming. That's why it’s so important to really understand what you need — like, what kind of heat it should produce and the environment it’s going to be working in. These heaters aren’t one-size-fits-all; they’re built to handle specific demands, which means they give you efficient heat transfer, precise control over temperatures, and yes, they can even help save energy.

In this guide, I’ll walk you through the key things to think about when choosing a customized industrial heater that’s right for your setup. We’ll talk about how to figure out the right heat output, check whether the materials are compatible, and keep safety and installation in mind. Honestly, paying attention to these little details can make a big difference. Taking the time to get a grip on everything means you’ll invest in a heater that not only fits your current needs but can also handle whatever the industry throws at you down the line.

Understanding the Types of Customized Industrial Heaters Available

When selecting a customized industrial heater, it's essential to understand the various types available to meet your specific needs. Industrial heaters can broadly be categorized into electric heaters, gas-fired heaters, and fluid-based systems. Electric heaters, often valued for their efficiency and flexibility, are suitable for environments where precise temperature control is required. Gas-fired heaters, on the other hand, are ideal for large spaces that need rapid heating, making them an excellent choice for warehouses or factories. Fluid-based systems utilize hot water or steam, providing uniform heating and are commonly used in processes that demand consistent thermal conditions.

**Tips:** When considering your options, think about the specific application of the heater. Evaluate the heating capacity needed; for instance, larger industrial spaces will require heaters with higher output. Moreover, consider the operating environment, as heaters designed to withstand harsh conditions may be necessary for specific applications.

Additionally, customization allows for integrating features like temperature controls and safety mechanisms. Ensure you assess the installation and maintenance requirements, as these can significantly influence your long-term operational costs. Always consult with industry experts to gain insights into the best configurations for your workspace, helping you to make an informed decision that aligns with your operational goals.

Evaluating the Heating Requirements for Your Specific Application

When evaluating the heating requirements for a specific application, it's essential to consider the unique circumstances of your operation. Factors such as the size of the space, the type of materials being heated, and the desired temperature profile are crucial in determining the right industrial heater. Begin by assessing the square footage and insulation of the area, as this will aid in selecting a heater that offers adequate coverage and efficiency.

Tips: Measure the square footage of the area to get an accurate understanding of the heating load required. Also, consider the thermal characteristics of the materials you plan to heat. Some substances may require more precise temperature control, which could influence your choice of heater type.

Additionally, think about the ambient conditions where the heater will be used. If your application involves outdoor or harsh environments, ensure that the heater is designed to withstand such conditions. Understanding the specific heating needs not only optimizes performance but also enhances energy efficiency and operational safety.

Tips: Evaluate the installation requirements, including power supply and ventilation, as these can impact the overall effectiveness of the heating solution. Keep an eye on the operational costs associated with different heating methods; sometimes a higher initial investment can lead to long-term savings through improved efficiency.

Key Features to Consider When Selecting an Industrial Heater

When selecting an industrial heater, one must prioritize key features that align with specific operational needs. One critical factor is the heater's temperature range. Depending on the application—be it heating fluids, air, or solid materials—understanding the required temperature parameters is essential. According to a report from the International Energy Agency (IEA), industrial sectors account for approximately 34% of global energy consumption, emphasizing the importance of energy efficiency in heater selection. Opting for heaters with robust temperature control can significantly reduce energy costs, making them a worthwhile investment.

Another vital feature to consider is the heater's material composition and durability. Industrial environments can be harsh, with exposure to contaminants and varying conditions. Post-2020 data from the U.S. Department of Energy indicates that equipment failures often result from inadequate material resilience, leading to costly downtimes. Choosing heaters crafted from high-quality, corrosion-resistant materials can enhance longevity and performance. Additionally, assessing the heater’s installation and maintenance requirements can provide insights into operational efficiency—heaters that offer easy installation and low maintenance demands can yield significant labor cost savings.

Finally, evaluating safety features is paramount. Industrial heaters should be equipped with fail-safes and automatic shut-off controls to prevent accidents. The National Fire Protection Association (NFPA) reports that improper heating equipment is a major contributor to industrial accidents. Therefore, integrated safety measures are not just optional but essential for ensuring workplace safety while maximizing operational productivity. By focusing on these key features—temperature range, material durability, and safety—industries can choose the most suitable customized industrial heater for their unique needs.

Key Features to Consider When Selecting an Industrial Heater

Materials and Construction: Choosing the Right Specifications

When selecting the optimal customized industrial heater, material selection and construction specifications play a critical role in meeting operational demands. Various heating applications may require different materials, with stainless steel and high-grade aluminum often preferred for their resistance to corrosion and temperature stability. According to the latest industry reports, approximately 66% of industrial heating applications favor materials that can withstand extreme conditions, highlighting the need for durable construction. Ensuring that the heater’s casing and internal components are made from materials best suited for the specific heat transfer efficiency and environmental conditions can significantly enhance performance and longevity.

In addition to material selection, construction specifications such as insulation type and thickness directly impact heat retention and energy efficiency. High-performance insulating materials can reduce energy loss by up to 30%, making them crucial for maintaining optimal temperatures and lowering operational costs. A recent analysis indicates that poorly insulated equipment can lead to increased energy consumption, resulting in annual losses of around 20-25% in energy bills for industrial operators. Carefully evaluating insulation options alongside core material choices can provide substantial benefits, thus ensuring that the customized industrial heater not only meets immediate thermal requirements but also supports long-term energy savings and sustainability goals.

Energy Efficiency and Cost Considerations in Industrial Heaters

When selecting a customized industrial heater, energy efficiency and cost considerations are paramount. An energy-efficient heater not only reduces operational costs but also minimizes the environmental impact of your operations. To effectively assess energy efficiency, look for heaters that offer advanced features such as precise temperature control, programmable settings, and insulation that reduces heat loss. These features ensure that the heater operates at its optimal level, providing the necessary heat without excessive energy consumption.

In addition to energy efficiency, cost considerations should encompass initial investment, maintenance expenses, and long-term energy expenses. While some heaters may have a higher upfront cost, their energy-efficient designs can result in significant savings over time. It's essential to conduct a cost-benefit analysis that factors in the lifespan of the heater, potential downtimes, and energy usage rates. Choosing an industrial heater that balances both efficiency and cost-effectiveness can lead to better performance and lower operational costs, ultimately enhancing productivity and profitability in your industrial processes.

Safety Standards and Compliance for Customized Heating Solutions

When selecting a customized industrial heater, safety standards and compliance should be a primary consideration. Industrial heating solutions must adhere to industry regulations to ensure the protection of both personnel and equipment. Compliance with standards such as those set by the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL) guarantees that the heater is designed, manufactured, and tested to meet specific safety criteria. Proper documentation and certification are crucial, as they not only validate the heater’s safety but also mitigate risks associated with overheating, electrical failures, or hazardous emissions.

Additionally, it’s important to evaluate the customized heater's design for safety features. Look for elements such as thermal cut-offs, safety shut-off valves, and adequate insulation to prevent burns and heat loss. Ensure that the heater is equipped with current monitoring technologies that can provide alerts for abnormal functionality. By choosing a heating solution that prioritizes safety and compliance, businesses can protect their workforce and enhance operational reliability, minimizing potential downtime caused by safety-related incidents.

Consulting Experts: When and How to Seek Professional Advice

When it comes to selecting a customized industrial heater, seeking professional advice can significantly streamline the decision-making process. Experts can provide valuable insights into the specific heating requirements of your facility, including considerations such as the type of materials being heated, the size of the space, and energy efficiency. Knowing when to consult an expert is crucial; ideally, this should occur early in the project planning phase. This early engagement allows for a thorough assessment of your needs and helps to avoid costly mistakes down the line.

During the consultation, it's essential to come prepared with detailed information about your heating requirements. Discussing your specific applications, including temperature ranges and heating durations, can help professionals recommend tailored solutions. Additionally, experts can assist in identifying the latest technologies and materials that meet industry standards, ensuring that your customized heater is not only effective but also safe and compliant with regulations. By utilizing their knowledge and experience, you can choose an industrial heater that aligns perfectly with your operational goals and budget.

FAQS

: The main types of customized industrial heaters include electric heaters, gas-fired heaters, and fluid-based systems. Electric heaters are known for efficiency and precise temperature control, gas-fired heaters are suitable for rapid heating in large spaces, and fluid-based systems provide uniform heating using hot water or steam.

To determine the right heating capacity, assess the size of your industrial space and the specific heating needs. Larger areas typically require heaters with higher output to ensure effective heating.

Recommended materials for customized industrial heaters include stainless steel and high-grade aluminum, as they offer resistance to corrosion and maintain temperature stability, which is crucial for performance.

Insulation impacts heat retention and energy efficiency significantly. High-performance insulating materials can reduce energy loss by up to 30%, making them essential for maintaining optimal temperatures and minimizing operational costs.

When customizing an industrial heater, consider the specific application, required heating capacity, operating environment, and potential integration of features like temperature controls and safety mechanisms.

Poor insulation can lead to increased energy consumption, resulting in annual losses of approximately 20-25% in energy bills for industrial operators, highlighting the importance of selecting adequate insulation options.

Consulting with industry experts is important to gain insights into the best configurations that align with your operational goals, ensuring the chosen heater meets specific functional and environmental needs.

Customized industrial heaters can integrate features such as advanced temperature controls and safety mechanisms, enhancing their functionality and operational reliability.

Construction specifications, including insulation type and thickness, directly affect heat retention and energy efficiency, impacting the overall performance and longevity of the heater.

Selecting materials suited to withstand extreme conditions and maximize heat transfer efficiency can significantly enhance the heater's performance and longevity, ensuring it meets operational demands effectively.

Conclusion

Choosing the best customized industrial heater involves several critical considerations to ensure it meets specific operational needs. First, it's essential to understand the various types of customized industrial heaters and evaluate the heating requirements specific to your application. Key features such as control mechanisms, size, and portability should be taken into account, alongside the materials and construction specifications that align with environmental conditions and safety standards.

Additionally, organizations must assess energy efficiency and overall cost implications, as these factors impact long-term sustainability and budget. Compliance with safety standards is paramount when implementing customized heating solutions, ensuring that equipment meets regulatory requirements. Finally, consulting industry experts can provide valuable insights and guidance in selecting the right customized industrial heater, helping to navigate the complexities involved in the decision-making process. By addressing these aspects thoroughly, businesses can make informed choices that enhance operational efficiency and safety.

Related Posts

-

Understanding the Efficiency and Applications of Industrial Electric Heaters in Modern Manufacturing

-

The Ultimate Guide to Choosing the Best Industrial Flange Heater Suppliers for Your Needs

-

Top 5 Benefits of Choosing Customized Industrial Heaters for Your Business

-

Top 10 Industrial Circulation Heaters: Best Picks for Optimal Heating Solutions

-

How to Optimize Your Industrial Heater Bundle Pricing for Maximum Efficiency and Cost Savings

-

Unlocking Efficiency: The Benefits of Customized Industrial Heaters for Your Business

Blog Tags: