How to Choose the Best Industrial Immersive Heater for Your Needs

Table of Contents

- Understanding Industrial Immersive Heaters and Their Applications

- Factors to Consider When Choosing an Immersive Heater

- Types of Industrial Immersive Heaters Available in the Market

- Evaluating Heat Capacity and Energy Efficiency Requirements

- Assessing Safety Features and Compliance Standards

- Importance of Maintenance and Support in Heater Selection

- Cost Analysis and Budgeting for Industrial Immersive Heaters

- Essential Insights on Flange Type Immersion Heaters: Applications, Benefits, and Selection Guide

- FAQS

- Conclusion

- Related Posts

Picking the right industrial immersive heater for your facility isn’t just a small decision — it can really make a difference in how smoothly your operations run and how much energy you end up using. With so many options out there, it’s easy to feel a bit overwhelmed. That’s why it’s important to understand what factors actually influence a heater’s performance and how to pick the best one for your specific needs. Think of this as a helpful guide to walk you through the process, pointing out the key things you should keep in mind so you feel confident you’re making a smart investment.

Industrial immersive heaters are absolute essentials in many fields — from manufacturing and food processing to chemical treatments — especially when precise temperature control is needed. As industries keep evolving, the push for more advanced heating solutions grows stronger, which means getting a good handle on different technologies and how they can be applied is super important. We’ll cover stuff like heater design, energy efficiency, safety features, and maintenance — basically giving you a full overview so you can make a smarter choice.

All in all, finding the best industrial immersive heater comes down to matching your specific needs with the right tech. Do that, and you’ll improve your operations while also staying on top of energy savings. With the right info and a little careful thought, you’ll be all set to pick a heater that hits your performance goals and keeps energy costs under control.

Understanding Industrial Immersive Heaters and Their Applications

Industrial immersive heaters are specialized devices designed to efficiently transfer heat to various materials and processes. They utilize advanced technologies to create a controlled environment where heat is delivered directly to the substance being processed, rather than heating the surrounding air. This method enhances energy efficiency and reduces waste, making immersive heaters highly effective for applications in industries such as plastics, chemical processing, food manufacturing, and metalworking.

The applications of industrial immersive heaters are diverse and extend to several critical processes. For instance, in the plastics industry, these heaters are employed to melt and process thermoplastic materials, ensuring consistent temperatures for optimal flow and shaping. In chemical processing, they facilitate reactions by maintaining precise temperatures that are essential for various chemical interactions. Additionally, in food manufacturing, immersive heaters ensure that products receive uniform heating, which is crucial for food safety and quality. By understanding these applications, businesses can make informed decisions about which immersive heater best meets their operational needs.

Factors to Consider When Choosing an Immersive Heater

When choosing an industrial immersive heater, there are several key factors to consider to ensure you select the right model for your specific needs.

First and foremost, assess the heating capacity required for your operation. This involves determining the size of the area you need to heat, as well as the materials being processed.

Different applications may demand varying temperature ranges, so understanding the thermal requirements of your operation is crucial for optimal performance.

Another important factor is the energy efficiency of the heater. Look for models that offer advanced energy-saving features, as these can significantly reduce operational costs over time.

Consider the type of energy source as well, whether it's electric, gas, or another alternative. Each type has its own advantages and challenges regarding setup and operational costs.

Additionally, examine the safety features available, especially in industrial environments where high temperatures and heavy machinery are involved.

Ensuring your chosen heater has robust safety mechanisms can protect against overheating and potential hazards, contributing to a safer workplace.

Types of Industrial Immersive Heaters Available in the Market

When exploring the types of industrial immersive heaters available in the market, it's essential to understand the various options tailored to specific operational needs. Immersive heaters primarily fall into three categories: electric, gas, and liquid immersion heaters. Electric heaters are popular due to their efficiency and precise temperature control, making them ideal for applications that require consistent heat without significant fluctuations. Gas heaters, on the other hand, are favored for larger operations where rapid heating is necessary, as they can provide high outputs efficiently.

Liquid immersion heaters are another vital category, commonly used in processes where heat needs to be transferred directly to a fluid medium. They are crucial in industries such as chemical processing, food production, and renewable energy systems. Each type offers unique advantages depending on the operational demands, energy availability, and environmental considerations.

Tips: When choosing the right industrial immersive heater, consider the specific heat output required for your application. Assess your facility's energy infrastructure to determine whether electric or gas options are more feasible. Additionally, evaluate safety features available with each type to ensure that the heater can operate within the safety standards required for your industry.

Evaluating Heat Capacity and Energy Efficiency Requirements

When selecting the best industrial immersive heater, evaluating heat capacity and energy efficiency requirements is crucial. Heat capacity determines the amount of heat energy the heater can deliver over time, which directly impacts operational efficiency and productivity. According to a report from the U.S. Department of Energy, heating accounts for approximately 30% of industrial energy consumption. This statistic underscores the importance of choosing a heater that can provide sufficient heat for a given application while minimizing energy waste.

In terms of energy efficiency, the industry standard is often rated by the thermal efficiency percentage of the heating element. A higher efficiency rating translates to lower operational costs and reduced environmental impact. For example, heaters with a thermal efficiency of 90% or above can significantly reduce energy bills compared to those with lower efficiencies. Additionally, advanced technologies such as variable frequency drives and smart controls can further enhance energy savings, yielding up to a 20% reduction in energy consumption when integrated into the heating system. Making informed choices in heat capacity and energy efficiency will contribute to achieving a balance between performance and cost savings in industrial heating applications.

Assessing Safety Features and Compliance Standards

When selecting an industrial immersive heater, safety features and compliance with industry standards are paramount. The design should incorporate multiple safety mechanisms, such as thermal cut-offs, over-temperature protection, and robust construction materials. These features help mitigate the risk of overheating and potential hazards associated with industrial heating processes. Furthermore, heaters should be equipped with safety indicators that clearly show operational statuses, minimizing the chances of accidents due to human oversight.

Compliance with local and international safety standards is another crucial aspect to consider. Ensure that the chosen heater meets relevant certifications, such as UL, CE, or ISO standards, which indicate that the equipment has undergone rigorous testing for safety and efficacy. Additionally, assess whether the manufacturer provides detailed documentation proving compliance and includes safety instructions for installation and operation. By prioritizing these safety features and compliance standards, you can ensure a safer working environment and reduce the risks associated with industrial heating applications.

Safety Features of Industrial Immersive Heaters

Importance of Maintenance and Support in Heater Selection

When selecting an industrial immersive heater, maintenance and support should play a crucial role in your decision-making process. A study conducted by the Industrial Heating Equipment Association indicates that preventive maintenance can extend the life of heating elements by up to 50%, thus significantly reducing downtime and operational costs. Regular maintenance helps identify potential issues before they escalate, providing a continuous and reliable heat source essential for many industrial applications.

Moreover, the level of support provided by the heater manufacturer is critical. Effective after-sales support, including timely access to replacement parts and expert guidance, can dramatically influence the productivity of your operations. For example, research from a leading industrial efficiency report suggests that companies that ensure robust support systems experience a 30% decrease in equipment failures compared to those that do not. Choosing a heater from a supplier that emphasizes strong technical support can not only enhance performance but also foster a more resilient operational environment.

Cost Analysis and Budgeting for Industrial Immersive Heaters

When considering the acquisition of an industrial immersive heater, understanding the cost implications is crucial. The initial purchase price is a primary factor, but organizations must also account for the long-term operational costs. This includes energy consumption, maintenance requirements, and the expected lifespan of the heater. Conducting a thorough cost analysis helps businesses determine the total cost of ownership and identify potential savings over time.

Budgeting for industrial immersive heaters involves setting aside funds not only for the purchase but also for installation and ongoing operational expenses. Companies should evaluate their heating needs and the scale of their operations, as this can significantly influence the type and specifications of the heater required. It’s essential to engage with multiple suppliers to compare pricing and warranty offerings, which can aid in building a budget that accommodates all aspects of the investment. By meticulously planning for these costs, businesses can ensure they make informed purchasing decisions that align with their financial capabilities and operational goals.

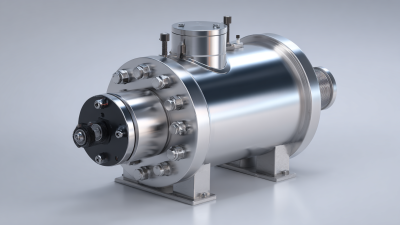

Essential Insights on Flange Type Immersion Heaters: Applications, Benefits, and Selection Guide

Flange type immersion heaters are crucial in numerous industrial applications due to their efficient heating capabilities. These devices function by using an electric resistance heater submerged in a fluid, typically water, to provide direct heating. The design permits reliable operation even at elevated temperatures and pressures, making them ideal for processes that require precise temperature control. According to industry reports, the global immersion heater market size is projected to reach $1.3 billion by 2027, reflecting a significant demand across various sectors, including oil and gas, chemical processing, and food production.

The benefits of flange type immersion heaters are multifold. Their construction allows for easy installation and maintenance, and they can be fitted with various size flanges to match the specifications of different systems. Additionally, these heaters provide rapid heating solutions, which can enhance energy efficiency in operations. Studies suggest that leveraging immersion heaters can reduce heating times by up to 50%, translating into substantial cost savings for large-scale operations. Moreover, their compatibility with different fluids expands their application range, from heating water to industrial oils, making them a versatile choice in many environments.

When selecting a flange type immersion heater, factors such as wattage, material compatibility, and design specifications must be considered. Proper sizing is paramount to ensure optimal heating performance without overheating the system or causing thermal stress. For instance, the Thermal Efficiency Report indicates that choosing the correct watt density can improve heater lifespan and reduce energy consumption. With a thorough understanding of application requirements and environmental factors, businesses can make informed decisions that maximize efficiency and safety in their heating solutions.

FAQS

: Industrial immersive heaters are devices designed to transfer heat efficiently to materials by directly warming the substance being processed rather than heating the surrounding air. This method enhances energy efficiency and reduces waste.

These heaters are utilized in various industries, including plastics, chemical processing, food manufacturing, and metalworking, where controlled heat delivery is critical.

Key factors include heat capacity, energy efficiency, safety features, and compliance with industry standards. Evaluating these characteristics will help ensure the heater meets operational needs effectively.

Heat capacity determines the amount of heat energy a heater can deliver over time, impacting operational efficiency and productivity, which is essential for effective process management.

Higher thermal efficiency ratings lead to lower operational costs. Heaters with efficiency ratings of 90% or above can significantly reduce energy bills, thereby minimizing environmental impact.

Technologies such as variable frequency drives and smart controls can improve energy savings by up to 20% when integrated into the heating system, enhancing overall efficiency.

Essential safety features include thermal cut-offs, over-temperature protection, and robust construction materials. These help mitigate risks related to overheating during industrial heating processes.

Compliance with safety standards, such as UL, CE, or ISO, ensures that the equipment has undergone testing for safety and efficacy, reducing risks and promoting a safer working environment.

Manufacturers should provide detailed documentation proving compliance with safety standards, along with safety instructions for installation and operation to ensure safe usage.

By prioritizing safety features and compliance standards, businesses can create a safer working environment, reducing the risks associated with industrial heating applications.

Conclusion

Choosing the right Industrial Immersive Heater is crucial for optimizing operational efficiency and ensuring safety in various industrial applications. Understanding the functions and applications of these heaters is the first step, followed by assessing key factors such as heat capacity, energy efficiency, and safety compliance standards. It’s essential to evaluate the different types available in the market, as well as maintenance requirements and support options, to ensure long-term reliability.

Additionally, a thorough cost analysis and budgeting are vital to make an informed purchase decision. By considering these elements, businesses can select an Industrial Immersive Heater that meets their specific needs while maintaining energy efficiency and safety standards.

Related Posts

-

Revolutionizing Heat Solutions with Industrial Immersive Heater Technology

-

Discovering the Future: How Electric Process Heater Manufacturers are Revolutionizing Energy Efficiency

-

Top 10 Industrial Process Heaters for Efficient Temperature Control

-

The Ultimate Guide to Choosing the Best Industrial Flange Heater Suppliers for Your Needs

-

Top 5 Industrial Electric Heater Manufacturers to Watch in 2025

-

How to Choose the Right Air Duct Heater Factory for Your Needs

Blog Tags: