How to Choose the Right Ansi Flange Immersion Heater for Optimal Energy Efficiency

Table of Contents

- Understanding ANSI Flange Immersion Heater Specifications for Energy Efficiency

- Key Factors Influencing Energy Consumption in ANSI Flange Immersion Heaters

- Comparative Analysis of Material Types for Optimal Thermal Conductivity

- Measurement of Heater Performance: BTU Output and Energy Rating in Immersion Heaters

- Installation Practices that Enhance Efficiency in ANSI Flange Immersion Heating Systems

- Lifecycle Cost Analysis: Choosing the Right ANSI Flange for Long-Term Energy Savings

- Optimizing Industrial Heating Solutions: The Essential Role of Flange Immersion Heaters

- FAQS

- Conclusion

- Related Posts

In today’s world where everyone’s really keen on saving energy, picking the right heating solution is super important—not just for keeping energy costs down, but also for safety. You’ve probably heard of Ansi Flange Immersion Heaters; they’re a go-to choice for tons of industrial setups because they heat liquids directly and effectively. But with so many options out there, it’s definitely worth understanding what really makes one of these heaters perform well.

At Jiangsu Weineng Electric Co., Ltd., we’ve got tons of experience in making explosion-proof electric heaters, from designing to manufacturing and getting them up and running. This guide’s gonna walk you through the key things to think about when choosing the right Ansi Flange Immersion Heater, so you can get the most out of your energy and stay safe—all at the same time.

Understanding ANSI Flange Immersion Heater Specifications for Energy Efficiency

When you're choosing the right ANSI flange immersion heater, it’s really important to get a good handle on the specs that influence energy efficiency. These heaters are built for precise heating tasks and can actually be customized to fit specific operational needs. The way you set up and select these heaters can make a big difference in how much energy you end up consuming — I’ve personally seen reports saying that tweaking heater configurations can save up to 30% of energy in industrial settings. Things like watt density, the materials used, and how well the fluid conducts heat all play a part in boosting energy efficiency.

At Jiangsu Weineng Electric Co., Ltd., we’ve got solid experience in designing and making explosion-proof electric heaters. We use that expertise to create solutions that not only perform well but also help cut down on energy use. Industry reports have shown that choosing the right insulation material, along with a good heater design, can actually cut heat loss and bump up efficiency even more. Thanks to our extensive background in crafting custom heating solutions, we’re able to guide clients in picking out the perfect ANSI flange heater specs for their unique processes. This way, they get both safety and energy savings. We’re all about blending innovation with proven engineering practices to deliver high-quality heating products that support sustainability and help save money on energy bills.

Key Factors Influencing Energy Consumption in ANSI Flange Immersion Heaters

When you're choosing an ANSI flange immersion heater, it’s really important to get a good handle on what influences energy use. One of the main things to look at is the heater’s watt density—that’s essentially how much power it puts out per square foot of the heating surface. The U.S. Department of Energy notes that heaters with higher watt density can heat fluids faster, but they might also guzzle more energy if they’re not the right size for what you’re doing. For example, a 2,000-watt heater in a well-insulated tank can actually save you quite a bit on energy compared to a lower wattage one that’s running longer just to get the job done.

Another thing to keep in mind is the material and design of the heater. Typically, high-quality materials like stainless steel or Inconel are better because they transfer heat more efficiently and last longer. The Thermal Equipment Manufacturers Association points out that heaters designed specifically for certain applications—like those with optimized surface areas—can cut energy use by up to 30%. Plus, using advanced controls to manage temperature effectively can prevent wasting energy and help extend the life of the heater. When you really think about these factors, you’re more likely to pick a heating setup that’s both efficient and reliable for industrial processes.

Comparative Analysis of Material Types for Optimal Thermal Conductivity

So, when you're picking out an ANSI flange immersion heater, the materials you choose really matter — they can make a big difference in how well it conducts heat and how energy-efficient it is. I recently read a report from the Energy Efficiency Partnership, and it turns out that heating elements made from high-quality stainless steel tend to transfer heat way better than older materials like cast iron. That’s a win because it can help cut down energy use by around 15%, which adds up to lower costs over time. Pretty cool, right?

Now, a couple of tips if you're trying to decide on materials: think about what your specific process needs. For example, if you're working with really harsh chemicals, something like Hastelloy or Inconel might be the way to go since they resist corrosion and last longer. But if your situation isn’t so tough — maybe just regular stuff — then carbon steel could do the job without breaking the bank.

Oh, and don’t forget about insulation! The right insulation can really boost energy savings by preventing heat from escaping. The Department of Energy says that good insulation can cut heat loss by up to 30%. So, when you’re buying an ANSI flange immersion heater, make sure you look at both the material choice and the insulation options — they’re both key to getting the best performance and saving energy.

Measurement of Heater Performance: BTU Output and Energy Rating in Immersion Heaters

When you're picking out an ANSI flange immersion heater, it's really important to get a handle on its performance stats—things like BTU output and energy rating. These numbers are key because they tell you how well the heater will perform and how much energy it might use. So, BTU, which stands for British Thermal Units, basically measures how much heat the heater can transfer. The higher the BTU, the more powerful the heater is. According to the folks at the U.S. Department of Energy, systems boasting a 90% or higher energy rating can really help cut down on costs—by making heat transfer more efficient and reducing unnecessary energy waste.

To make sure you pick the right heater, think about what you actually need it for. For example, if you're heating up a big volume of liquid, you’ll probably want a heater with a higher BTU to keep things running smoothly without having to keep it on forever. Also, it’s smart to take a look at how long you'll be running the heater and what local energy prices are—those details can help you figure out how much money you'll save with a more efficient model.

**A couple of quick tips:**

1. Always compare the energy ratings across different models. Units with Energy Star labels or similar certifications are usually your best bet—they mean the heater is pretty efficient.

2. Do some math! Figure out exactly what your heating needs are—what type of fluid you’re heating, how much, and how much you want to raise the temperature—and choose a BTU that matches. This way, you’ll avoid oversizing, which can lead to higher energy use and bigger bills.

How to Choose the Right Ansi Flange Immersion Heater for Optimal Energy Efficiency - Measurement of Heater Performance: BTU Output and Energy Rating in Immersion Heaters

| Heater Model | Power Rating (kW) | BTU Output | Energy Efficiency Rating | Max Operating Temp (°F) |

|---|---|---|---|---|

| Model A | 3 | 10,227 | 93% | 200 |

| Model B | 6 | 20,454 | 90% | 450 |

| Model C | 9 | 30,681 | 88% | 600 |

| Model D | 12 | 40,908 | 85% | 700 |

Installation Practices that Enhance Efficiency in ANSI Flange Immersion Heating Systems

When you're setting up ANSI flange immersion heaters, doing it the right way can really make a difference in saving energy. One of the most important tips is to make sure you install the heater at the right spot inside the tank or vessel. You wanna position it deep enough so it stays submerged—you definitely don’t want it to run dry! At the same time, placing it correctly helps maximize the heat transfer area, so things heat up efficiently. Getting this part right not only boosts performance but can also help the heater last longer.

Another thing to keep in mind is insulation. Properly insulating the tank can cut down on heat loss big time, which means less energy wasted. Using good quality insulation materials around the tank keeps the temperature steady without demanding too much energy. And don’t forget, checking the insulation regularly is a good idea—over time, it can break down or settle, and that could impact how well your system works.

Finally, investing in top-notch flanges and seals that match your setup is key. These help keep everything sealed tight, preventing leaks and ensuring heat gets transferred efficiently. Choosing the right materials for these parts can really boost the overall dependability of your heating system, which, in the long run, saves you both time and money.

Energy Efficiency of ANSI Flange Immersion Heaters

This chart illustrates the energy efficiency ratings of different ANSI flange immersion heaters based on their operating temperatures and installation practices. Higher efficiency ratings indicate better energy performance and cost savings.

Lifecycle Cost Analysis: Choosing the Right ANSI Flange for Long-Term Energy Savings

When you're choosing an ANSI flange immersion heater, taking the time to do a full lifecycle cost analysis can really pay off in the long run—you know, when it comes to saving energy and cutting costs. The U.S. Department of Energy reports that nearly a quarter of all energy used in manufacturing is for heating, which is pretty eye-opening. Picking the right heater can make a big difference; some studies suggest you could save up to 30% on energy costs over its lifetime just by going for a more efficient model. It’s kind of like making an investment that keeps giving back.

Going for a high-quality ANSI flanged heater might seem pricier at first, but it usually means lower maintenance headaches and better reliability down the line. According to some info from the Thermoelectric Power Systems journal, the higher initial cost for more efficient systems often gets balanced out pretty quickly because you spend less on operating expenses. Basically, better efficiency means the heater heats up quicker and wastes less energy—so you get more done and spend less on energy bills. When industries weigh both the upfront costs and the ongoing energy savings, they can make smarter choices that really pay off over the life of the equipment.

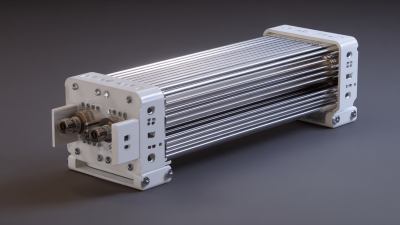

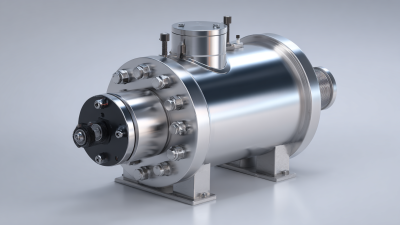

Optimizing Industrial Heating Solutions: The Essential Role of Flange Immersion Heaters

In the realm of industrial heating solutions, flange immersion heaters play a vital role in enhancing efficiency and optimizing processes. These heaters, designed for direct contact with liquids, oils, and other viscous fluids, ensure that heat is applied where it is needed most—right within the tank. According to recent industry reports, immersion heaters can achieve energy efficiencies of up to 90%, translating to significant savings in operational costs for manufacturers.

Flange immersion heaters are engineered for a variety of applications, ranging from chemical processing to food production. The ability to install them through various options in heating tanks allows for flexibility in design and implementation. Reports estimate that the market for industrial immersion heaters is projected to grow at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2026, underscoring the increasing reliance on these heating solutions across various sectors. As industries seek to optimize their heating processes, the adoption of immersion heaters stands out as a key strategy for improving overall system performance and efficiency.

Moreover, the durability and effectiveness of flange immersion heaters reduce the need for frequent maintenance, again contributing to lower operational costs. By ensuring consistent temperature control and minimizing waste, these heaters not only streamline production processes but also promote energy conservation initiatives that are becoming crucial in today’s environmentally conscious climate. With the ongoing advancements in technology, the performance and versatility of immersion heaters will only continue to enhance.

FAQS

: Watt density refers to the power output per square foot of heating surface in an immersion heater. Higher watt density can heat fluids faster but may lead to increased energy consumption if the heater is not appropriately sized for the application.

Heaters made from high-quality materials like stainless steel or Inconel offer better heat transfer efficiency and durability, which can reduce energy use by as much as 30% in certain applications compared to lower-quality materials.

High-performance insulation materials can minimize heat loss and further enhance energy efficiency, with improved insulation reportedly reducing energy losses by up to 30%.

Key performance metrics include BTU output, which measures the heater's ability to transfer heat, and the energy rating. A higher BTU output indicates a more powerful heating element, while energy ratings of 90% or higher help maximize heat transfer efficiency.

Selecting materials with superior thermal conductivity, such as high-grade stainless steel, can lead to an approximate reduction of 15% in energy consumption, significantly lowering operational costs over time.

Understanding specific heating requirements, such as fluid type, volume, and desired temperature rise, is crucial to selecting a heater with the appropriate BTU output, which helps avoid oversizing and reduces energy consumption and costs.

Look for immersion heaters with high energy ratings (like Energy Star certifications), optimized material choices, advanced control systems to regulate temperature, and effective insulation strategies.

A high BTU output heater enables efficient heating of large volumes of liquid without excessive run times, ensuring that heating demands are met without incurring high energy costs.

Yes, materials such as Hastelloy or Inconel are preferable for applications involving aggressive chemicals due to their corrosion resistance and durability.

Employing advanced control systems to regulate temperature and choosing high-quality materials can help minimize energy waste and extend the lifespan of the heating element.

Conclusion

Picking the right ANSI Flange Immersion Heater is really important if you want to get the most out of your industrial setup. Understanding the specific specs of these heaters can make a big difference in how much energy you end up using overall. Things like the materials used and how well they conduct heat are super important when you're trying to choose a heater that performs at its best. It’s also a good idea to take a close look at their BTU output and energy ratings — that way, you can really get a sense of how efficient they are. Plus, how you install them can make a big difference in how well they work, so don’t overlook that part either.

Over at Jiangsu Weineng Electric Co., Ltd., we put a lot of expertise into designing and making explosion-proof electric heaters, ensuring our ANSI Flange Immersion Heaters are top-notch when it comes to energy efficiency. We also help our customers understand the bigger picture by doing lifecycle cost analyses — so they’re not just thinking about what it costs right now, but also about the long-term energy savings. Our focus on quality design and manufacturing means businesses can count on reliable, efficient heating solutions that really get the job done.

Related Posts

-

Ultimate Guide to Choosing the Best China Flange Immersion Heater for Your Needs

-

The Ultimate Guide to Flange Industrial Heaters: Maximizing Efficiency and Safety in Your Operations

-

The Future of Finned Tube Heaters: Innovations Shaping Thermal Technology

-

The Ultimate Guide to Choosing the Best Industrial Flange Heater Suppliers for Your Needs

-

Ultimate Checklist for Sourcing Best China Industrial Heater Bundles in 2023

-

The Essential Ultimate Guide to Choosing the Best Explosion Proof Industrial Heater Suppliers

Blog Tags: