Unlocking Efficiency: The Benefits of Customized Industrial Heaters for Your Business

Table of Contents

- Understanding Customized Industrial Heaters and Their Importance

- Key Benefits of Tailored Heating Solutions for Business Efficiency

- Factors to Consider When Choosing Customized Industrial Heaters

- How Customized Industrial Heaters Enhance Energy Efficiency

- Common Applications of Customized Industrial Heating Solutions

- Tips for Selecting the Right Supplier for Industrial Heaters

- Exploring the Impact of Customized Industrial Immersion Heaters on Energy Efficiency: Insights from Recent Market Analysis Reports

- FAQS

- Conclusion

- Related Posts

In today's super competitive marketplace, businesses are always on the lookout for ways to boost efficiency and cut costs. One of the key solutions that’s been gaining traction is customized industrial heaters. These allow companies to fine-tune their heating systems to match their specific needs—which is pretty handy, right?

A recent report from ResearchAndMarkets shows that the industrial heating market is expected to grow around 5.6% annually between 2021 and 2026. That just shows how much demand there’s for energy-efficient heating options across different industries.

Take Jiangsu Weineng Electric Co., Ltd., for example. They’re a high-tech company specializing in explosion-proof electric heaters. With years of experience in designing, producing, and installing these heaters, Weineng is really pushing the envelope when it comes to tailored solutions. Their systems don’t just perform well—they’re also safe, meet strict industry standards, and give companies a real boost in productivity.

Investing in customized industrial heaters can make a huge difference—cutting downtime, improving efficiency, and ultimately helping businesses get more done with less hassle.

Take Jiangsu Weineng Electric Co., Ltd., for example. They’re a high-tech company specializing in explosion-proof electric heaters. With years of experience in designing, producing, and installing these heaters, Weineng is really pushing the envelope when it comes to tailored solutions. Their systems don’t just perform well—they’re also safe, meet strict industry standards, and give companies a real boost in productivity.

Investing in customized industrial heaters can make a huge difference—cutting downtime, improving efficiency, and ultimately helping businesses get more done with less hassle.

Understanding Customized Industrial Heaters and Their Importance

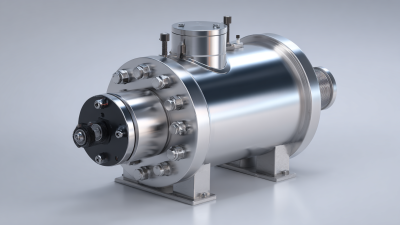

Customized industrial heaters are a real game-changer when it comes to making operations run smoother across different industries. Instead of relying on generic heating solutions, these tailored systems are built specifically for a company's unique needs, making sure that temperature control and heat distribution perfectly align with their production processes. The cool part? This kind of customization can really help cut down energy use, reduce heat loss, and boost overall productivity by giving precise heat exactly where it’s needed most.

And it’s not just about short-term gains. Customized heaters also help tackle industry-specific challenges—whether you're in food production, pharmaceuticals, or chemical processing. They help companies stay compliant with safety and quality standards, which is a huge plus. Plus, they give you the flexibility to adapt to shifting operational demands without having to rip out and replace a bunch of equipment. That kind of flexibility leads to better efficiency overall and saves money in the long run. All in all, investing in customized industrial heaters makes a lot of sense for any business looking to stay ahead of the game.

Key Benefits of Tailored Heating Solutions for Business Efficiency

Customized industrial heaters really pack a punch when it comes to boosting business efficiency. One of the coolest things about them is how they’re built to match exactly what your operation needs. Unlike those standard heaters you find off the shelf, these tailored solutions are designed specifically for your setup, ensuring everything runs smoothly and efficiently. It’s pretty neat how this kind of precision heating doesn’t just save energy but also cuts down on waste, which over time adds up to some serious cost savings.

And let’s not forget about productivity. When you’ve got reliable, consistent heat, your operations can stay on point—whether you’re drying, curing, or doing any temperature-sensitive work. Plus, these custom systems tend to fit right into your current setup without a fuss, so you can make quick adjustments without much hassle and avoid unnecessary downtime. All in all, having a customized industrial heater not only makes your process more efficient but can also give you a real leg up in the competitive market.

Factors to Consider When Choosing Customized Industrial Heaters

When you're picking out customized industrial heaters for your business, there are a few key things to think about to make sure they work well and run efficiently. First off, take a close look at what your specific heating needs are — kind of depends on what you're processing and the materials involved. Interestingly, a recent report from the International Energy Agency (IEA) mentioned that industrial heating makes up about 35% of global energy use in industries, so choosing the right heater really matters if you want to save energy and keep things running smoothly.

Another thing to keep in mind is the type of energy source your heater will use. For instance, electric heaters often tend to be more efficient and cost less to operate in lots of situations. The U.S. Department of Energy says that with a well-designed heating system, businesses can cut their energy costs by up to 20%. So, it's worth thinking about whether electric, gas, or hybrid options make the most sense for your budget and environmental goals.

**Pro tip:** It's always a good idea to chat with a heating engineer or specialist who can help analyze your facility’s unique needs. A pro can give you insights and recommend the best type of heater, making sure you get a setup that’s both efficient and reliable, and that won’t cause you a lot of headaches down the line.

**Another tip:** Don’t overlook how important customization can be. A tailored heater setup can improve heat distribution across your operation, cut down on energy waste, and make sure every part of your process gets the thermal energy it needs — basically, it makes everything run a lot smoother.

Unlocking Efficiency: Customized Industrial Heaters Performance Comparison

How Customized Industrial Heaters Enhance Energy Efficiency

Customized industrial heaters really play a crucial role when it comes to boosting energy efficiency across different manufacturing and production setups. Unlike those one-size-fits-all models, these tailored solutions are built to meet the unique heating needs of each specific process. When you fine-tune the heater specs to match what your operation requires, you can cut down on energy use quite a bit — which means lower running costs. Plus, because these heaters are engineered with precision, they deliver optimal thermal performance, minimizing heat loss and making sure you're making the most of the energy you're putting in.

On top of that, these custom heaters are designed to fit right into existing systems without a hitch, giving you better control over heat distribution. This kind of flexibility doesn’t just boost the overall efficiency of your process; it also helps extend the life of your equipment. Features like adjustable temperature controls and advanced insulation tech mean these heaters can perform well under all sorts of conditions.

Bottom line: investing in customized industrial heaters not only helps you hit your immediate energy-saving goals, but it also supports more sustainable practices. It’s a smart move that shows your company's really committed to innovation and caring for the environment.

Common Applications of Customized Industrial Heating Solutions

Custom industrial heating solutions are really gaining recognition these days — people are seeing just how versatile they can be across all kinds of industries. Whether it’s electric vehicles or medical tech, the advantages of having tailored heating systems are pretty clear: they boost operational efficiency and help meet specific energy needs. Take flexible printed heaters, for example. These little wonders are super thin and bendable, and they’re actually transforming how we approach heating in modern applications — offering efficient, customized solutions that match what different industries require.

Another big deal right now is industrial heat pumps. Not only do they play a big role in helping industries cut down their carbon footprint, but they’re also key players in waste heat recovery. The global market for waste heat recovery is projected to hit around USD 142.9 billion by 2034 — that’s a testament to how much energy-efficient tech is gaining importance. Investing in custom heaters gives businesses a chance to adopt innovative tech that really boosts performance and cuts down on energy use.

Pro tip: When you’re looking into custom industrial heating options, it’s a good idea to really evaluate what your specific needs are. Tweaking things like size, power, and energy source can make a huge difference in how efficient and reliable your setup is. And don’t forget — teaming up with experienced manufacturers can make the whole process smoother and ensure the design and implementation match your operational goals more closely.

Tips for Selecting the Right Supplier for Industrial Heaters

When you're choosing the right supplier for industrial heaters, it's really important to think about what your business actually needs. The outdoor heating market is booming—going from around $14 billion in 2025 to a whopping $21.5 billion by 2032, so having a trustworthy partner can make a big difference in how smoothly things run on your end. Ideally, your supplier should not only give you customized solutions that fit your specific situation but also truly understand the ins and outs of industrial heating. That way, you can be confident their heaters will meet the necessary industry standards.

Take Jiangsu Weineng Electric Co., Ltd. as an example—they're a supplier that really hits the mark, especially when it comes to explosion-proof electric heaters. They've got tons of experience in designing, manufacturing, and getting these units up and running. When you're checking out different suppliers, it’s super important to look into their technical know-how, how they treat customers, and the kind of support they offer even after the sale. A supplier who can be there for you throughout the entire product lifecycle doesn’t just make operations smoother — they can also help your business stay successful in the long run.

Unlocking Efficiency: The Benefits of Customized Industrial Heaters for Your Business

| Feature | Description | Benefits | Considerations |

|---|---|---|---|

| Energy Efficiency | Custom industrial heaters designed to minimize energy consumption. | Reduced operational costs and environmental impact. | Initial investment may be higher; analyze long-term savings. |

| Performance | Tailored heating solutions for specific applications. | Optimal heating results and product quality enhancement. | Ensure compatibility with existing systems. |

| Durability | Constructed from high-quality materials for long lifespan. | Lower maintenance costs and less frequent replacements. | Higher upfront cost; warranty options should be considered. |

| Customization | Designed to meet specific operational requirements. | Improved operational efficiency and tailored solutions. | Involves time and collaboration with manufacturers. |

| Supplier Reliability | Choosing established suppliers with a proven track record. | Ensures service quality and support. | Research and reviews to validate supplier credibility. |

Exploring the Impact of Customized Industrial Immersion Heaters on Energy Efficiency: Insights from Recent Market Analysis Reports

In recent market analysis reports, the role of customized industrial immersion heaters in enhancing energy efficiency has garnered significant attention. Immersion heaters, by design, are an efficient method for heating liquids, oils, or other viscous fluids because they operate directly within the medium being heated. This direct contact results in rapid heating, leading to notable energy savings. Recent studies indicate that businesses utilizing tailored immersion heaters can reduce energy consumption by up to 30% compared to traditional heating methods.

Furthermore, the customization aspect allows these heaters to cater to the specific requirements of different industries, ensuring optimal performance. For instance, heaters can be designed with varying watt densities to suit the viscosity and thermal requirements of the liquid being heated. According to a report by MarketsandMarkets, the global immersion heater market is expected to reach a value of $1.5 billion by 2025, driven by the increasing demand for energy-efficient heating solutions in sectors such as food processing, chemicals, and pharmaceuticals.

Moreover, recent data suggests that immersion heaters are not just versatile but also adaptable, capable of being installed through multiple configurations in heating tanks. This flexibility, combined with their energy efficiency benefits, underscores why customized industrial immersion heaters are becoming the preferred choice among manufacturers aiming to reduce operational costs while striving for sustainability.

FAQS

: Customized industrial heaters are tailored heating solutions designed to meet the specific requirements of a business, ensuring proper temperature control and heat distribution aligned with production processes.

They provide optimized performance by reducing energy consumption, minimizing waste, improving productivity, and allowing for seamless integration with existing operations.

They maintain ideal operational conditions crucial for processes like drying and curing, which leads to less downtime and greater productivity.

They help address unique industry challenges in sectors like food production and pharmaceuticals, ensuring compliance with safety and quality standards.

Businesses should evaluate suppliers based on their ability to offer customized solutions, knowledge of the industrial heating landscape, technical capabilities, and after-sales support.

By providing precise heating and reducing energy consumption and heat loss, tailored heaters help businesses save money over time.

Customized heaters allow businesses to adapt to changing operational demands without extensive equipment overhauls, boosting overall effectiveness.

Yes, their adaptability and efficiency can position a business for greater success and competitiveness in the market.

A supplier with extensive experience, like Jiangsu Weineng Electric Co., Ltd., can ensure that heaters meet industry standards and enhance operational processes through reliable support.

Conclusion

Customized industrial heaters are actually pretty essential for businesses looking to run smoothly and stay competitive. They offer tailored heating solutions that fit your specific needs, helping you improve efficiency without wasting energy. When you get it right, these heaters can give you better control over your processes, cut down on costs, and even boost safety standards—all pretty important if you want to stay ahead in today’s busy market.

Now, when you’re shopping around for customized industrial heaters, it’s good to keep a few things in mind—like what exactly you need them for, how energy-efficient they are, and whether the supplier is trustworthy. Jiangsu Weineng Electric Co., Ltd. is a solid choice here—they’ve got tons of experience designing and installing explosion-proof electric heaters. Picking the right supplier means you’ll get heating solutions that really work for your particular setup, making your operations more efficient and hassle-free.

Related Posts

-

How to Optimize Your Industrial Heater Bundle Pricing for Maximum Efficiency and Cost Savings

-

Understanding the Efficiency and Applications of Industrial Electric Heaters in Modern Manufacturing

-

How to Maximize Efficiency with China Industrial Heating Bundle Solutions

-

The Ultimate Guide to Choosing the Best Industrial Flange Heater Suppliers for Your Needs

-

Understanding Industrial Duct Heaters: Essential Insights for Optimal Performance and Efficiency

-

The Future of Heating: Innovations by Leading Industrial Electric Heater Manufacturers

Blog Tags: