Understanding the Efficiency and Applications of Industrial Electric Heaters in Modern Manufacturing

Table of Contents

- Efficiency Metrics: Analyzing Heat Transfer and Energy Utilization in Industrial Electric Heaters

- Comparative Performance: Electric vs. Traditional Heating Methods in Manufacturing Environments

- Cost Savings: Evaluating the Return on Investment for Electric Heating Solutions

- Applications Across Industries: The Versatility of Electric Heaters in Metalworking, Food Processing, and More

- Future Trends: Innovations in Electric Heating Technologies and Their Impact on Manufacturing Efficiency

- Enhancing Indoor Comfort: The Benefits of Customized Air Duct Heaters for Efficient Climate Control

- FAQS

- Conclusion

- Related Posts

In today’s world of modern manufacturing, industrial electric heaters are absolutely essential—they really help boost productivity and save energy at the same time. Honestly, if you look at the latest reports on the global electric heaters market, it's pretty impressive—they're estimating it’ll hit around $34 billion by 2025. That growth is largely thanks to new tech and a rising need for efficient heating options. Here at Jiangsu Weineng Electric Co., Ltd., we’re really proud to be a high-tech company dedicated to making explosion-proof electric heaters for all kinds of industrial uses. With years of experience under our belt—designing, producing, and getting these heaters up and running—we make sure our products meet industry standards, so they work well and keep everyone safe. As manufacturing keeps evolving, integrating industrial electric heaters isn’t just a trend—it’s gonna be key to tackling energy-saving goals and boosting operational efficiency. Basically, it’s a big step toward a more sustainable future for industrial heating solutions.

Efficiency Metrics: Analyzing Heat Transfer and Energy Utilization in Industrial Electric Heaters

Industrial electric heaters have really become a key part of modern manufacturing these days. They’re pretty much the go-to when it comes to efficiently transferring heat and using energy wisely. Honestly, understanding what affects these efficiencies is super important if you wanna get the most out of your production process. Things like the type of materials, the design details, and operating conditions all play a big role in how well these heaters perform. When you dig into these factors, manufacturers can improve heat distribution and cut down on wasted energy—making operations more sustainable and cost-effective.

Industrial electric heaters have really become a key part of modern manufacturing these days. They’re pretty much the go-to when it comes to efficiently transferring heat and using energy wisely. Honestly, understanding what affects these efficiencies is super important if you wanna get the most out of your production process. Things like the type of materials, the design details, and operating conditions all play a big role in how well these heaters perform. When you dig into these factors, manufacturers can improve heat distribution and cut down on wasted energy—making operations more sustainable and cost-effective.

At Jiangsu Weineng Electric Co., Ltd., we’ve got quite a bit of experience in designing and building explosion-proof electric heaters. We know every industrial application comes with its own challenges, and that’s why we focus on creating high-tech solutions that not only work like a charm but also keep safety and reliability front and center. By helping our customers optimize efficiency, we’re able to support their efforts to boost production, cut costs, and stay on top of strict safety rules. Overall, our dedication to quality and innovation really makes us stand out in the electric heater industry.

Comparative Performance: Electric vs. Traditional Heating Methods in Manufacturing Environments

You know, in today's world of manufacturing, how efficiently we heat things up really matters. Especially when you compare those industrial electric heaters to the more traditional methods. Lately, electric heaters are getting pretty popular because they let us control temperatures more precisely and save energy. I came across a study that showed these electric heaters can actually cut energy costs by as much as 30% compared to gas or oil-based systems. That’s a pretty big deal! Not only does this make operations smoother and more cost-effective, but it also lines up nicely with global efforts to cut down greenhouse gases — a real plus as industries are under more and more pressure to be greener.

And get this, advances in energy storage tech are really helping push electric heating even further. There was this comprehensive survey on energy storage solutions that pointed out how these systems make electric heating more dependable, since manufacturers can store energy during off-peak times. That not only helps cut costs but also reduces environmental impact. Plus, with new innovations in thermal energy storage — like capturing excess energy from renewable sources — electric heating gets even more appealing for companies trying to go the green route. So yeah, switching from old-school methods to electric options isn’t just a passing trend; it’s really a big step toward a more sustainable future for industrial manufacturing.

Cost Savings: Evaluating the Return on Investment for Electric Heating Solutions

These days, when it comes to manufacturing, electric heaters are really becoming a game-changer. They’re not just about keeping things running; they actually help save a ton on energy costs. Recent studies? They’re pretty clear—switching to electric heating can offer a solid return on your investment.

For instance, adding electric heaters can really cut down energy use compared to the old-school gas boilers. When you look at the big picture—total cost of ownership—it turns out that even if the upfront costs are a bit unpredictable, the long-term savings from lower operational expenses usually beat traditional heating methods.

Plus, stepping into electric heating goes hand-in-hand with efforts to be more energy-efficient and cut down greenhouse gases. The UK’s Seventh Carbon Budget even suggests that, by 2040, folks could save around £1,400 on household bills just by switching to electric heat. Not too shabby, right? And it’s not just about cost savings—these flexible electric heating solutions are also expected to give a nice boost to the power grid.

They handle the increased electricity demand while helping us move away from fossil fuels.

So, for manufacturers, investing in these techs means not only running more efficiently but also playing a part in sustainability goals. And let’s be honest, that kind of balance benefits everyone—businesses, the environment, and the economy alike.

Applications Across Industries: The Versatility of Electric Heaters in Metalworking, Food Processing, and More

Industrial electric heaters have really become essential tools in a bunch of different industries, especially in metalworking and food processing. In metalworking, you'll often find electric heaters being used for things like annealing, forging, and melting. According to a report from Grand View Research, the global market for industrial heating equipment is expected to hit about 15 billion dollars by 2025. And interestingly, electric heating solutions are taking up a larger slice of that pie because they’re more efficient and cheaper to run. These heaters do a great job of boosting productivity and giving precise temperature control—something that’s super important when working with metals that need even heating all around.

On the food side of things, electric heaters are just as crucial. They’re key players in cooking, pasteurization, and drying processes. As the industry pushes toward more energy-efficient options, the demand for electric heating systems has jumped quite a bit. MarketsandMarkets reports that the food processing equipment market is expected to grow from around 80 billion dollars in 2020 to over 103 billion in 2025. And a big reason for this growth? Electric heaters. They’re versatile and dependable, helping maintain consistent temperatures that are vital both for keeping food safe and for good quality. Overall, electric heaters are really showing off how adaptable they are across such a wide range of applications—no wonder they’re such a hot topic these days.

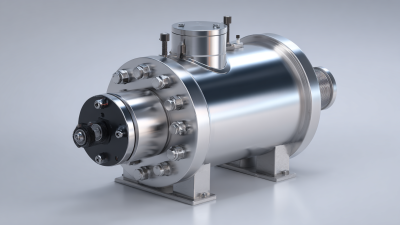

Efficiency and Applications of Industrial Electric Heaters

Future Trends: Innovations in Electric Heating Technologies and Their Impact on Manufacturing Efficiency

The world of industrial electric heating tech is changing pretty fast, and it's mostly thanks to some really cool innovations that are helping factories get more efficient and cut down on energy use. Believe it or not, recent research suggests that these advanced electric heating systems could boost energy efficiency by around 30% compared to the old-school fossil fuel heating methods. That’s a big deal, not just for saving money on operations but also because it lines up with global efforts toward sustainability.

Technologies like induction heating and super-advanced resistive heating are really making waves now, allowing manufacturers to fine-tune their processes and cut down on waste significantly.

But it’s not just about efficiency — the industry is also moving toward ‘smart’ heating systems that come with IoT features. Basically, these smart heaters can be monitored and analyzed in real time, which helps factories predict when they’ll need maintenance, avoid unexpected downtime, and bump up overall productivity. According to a report from Fortune Business Insights, the market for industrial electric heaters is expected to jump from about $2.85 billion in 2022 to a whopping $4.25 billion by 2030. That just shows how important these tech advancements are becoming. As these innovations keep evolving, they'll definitely shape what the future of manufacturing looks like, making electric heating technology an absolute must-have in today’s factories.

Enhancing Indoor Comfort: The Benefits of Customized Air Duct Heaters for Efficient Climate Control

Customized air duct heaters are revolutionizing indoor climate control by enhancing comfort and efficiency. Designed specifically for air-heating systems, these heaters play a crucial role in homes, leveraging surplus heat for effective heat recovery. This design enables homeowners to make the most out of their heating systems, leading to significant energy savings and improved indoor air quality.

One of the key benefits of integrating customized duct heaters is their ability to provide consistent warmth throughout living spaces. By strategically placing these heaters within air duct systems, they ensure that heated air is evenly distributed, reducing cold spots and promoting a more comfortable environment. Furthermore, with the increasing awareness of energy efficiency, these heaters allow for better regulation of indoor temperatures, adapting to the specific needs of each room and decreasing reliance on traditional heating methods.

Moreover, the adaptation of surplus heat for recovery purposes represents a significant advancement in sustainable heating practices. By utilizing excess heat generated from other systems, homeowners can reduce energy consumption and lower utility bills. This not only supports a greener lifestyle but also enhances the overall performance of the HVAC system, making customized air duct heaters an intelligent choice for modern residences focused on comfort and efficiency.

FAQS

: Industrial electric heaters offer improved heat transfer, energy utilization, precise temperature control, and the potential for energy savings of up to 30% compared to gas and oil-based systems.

Efficiency metrics are critical as they help identify factors such as material properties, design specifics, and operating conditions that enhance heat distribution and minimize energy losses, leading to optimized manufacturing processes.

Jiangsu Weineng Electric Co., Ltd. focuses on designing and producing explosion-proof electric heaters, providing high-tech solutions that enhance performance, safety, and reliability in various industrial applications.

They enhance operational efficiency and align with efforts to reduce greenhouse gas emissions, supporting manufacturers in decreasing their environmental footprints.

Advancements in energy storage technologies increase the reliability of electric heating by allowing for optimized energy consumption during off-peak hours.

This shift represents a movement towards more sustainable practices in industrial manufacturing, driven by energy efficiency and reduced environmental impacts.

Yes, electric heaters can achieve enhanced reliability when integrated with energy storage solutions, thus ensuring consistent performance and lower operational costs.

Innovations in thermal energy storage can store excess energy from renewable sources, further boosting the sustainability and cost-effectiveness of electric heating systems in manufacturing.

They reduce operational energy use, which contributes to lower greenhouse gas emissions and compliance with environmental regulations.

Electric heaters tackle challenges related to efficiency, safety, and performance while complying with stringent safety regulations in manufacturing processes.

Conclusion

The article titled 'Understanding the Efficiency and Applications of Industrial Electric Heaters in Modern Manufacturing' dives into the many aspects of industrial electric heaters. It really focuses on how efficient they are—especially when it comes to heat transfer and how effectively they use energy. The piece also compares electric heaters to traditional methods, highlighting how much money manufacturers can save and the solid return on investment. Plus, it points out how versatile these heaters are across different industries, like metalworking and food processing, really showing how they help boost operational efficiency.

Now, Jiangsu Weineng Electric Co., Ltd. is a big name in high-tech manufacturing. They're experts in making explosion-proof electric heaters and have loads of experience in designing, producing, and setting up these systems. The article even takes a look at what's coming next—talking about new innovations in electric heating tech that could make manufacturing even more efficient in the future. All in all, it makes a pretty strong case for electric heaters being a key part of modern factories and production lines.

Related Posts

-

How to Optimize Your Industrial Heater Bundle Pricing for Maximum Efficiency and Cost Savings

-

The Ultimate Guide to Choosing the Best Industrial Flange Heater Suppliers for Your Needs

-

Emerging Technologies for Industrial Flange Heater Solutions by 2025

-

Essential Checklist for Obtaining the Best Industrial Heater Bundle Quotes

-

Advantages of Choosing Customized Industrial Heater Manufacturers for Your Business Needs

-

5 Essential Tips for Choosing the Right Over The Side Circulation Heater

Blog Tags: