The Future of Finned Tube Heaters: Innovations Shaping Thermal Technology

Table of Contents

- Understanding Finned Tube Heaters: A Comprehensive Overview of Their Design

- Innovative Materials Enhancing Efficiency in Finned Tube Heater Performance

- The Role of Smart Technology in Modern Finned Tube Heater Solutions

- Energy Saving Potential of Finned Tube Heaters in Industrial Applications

- Future Trends: Integration of Finned Tube Heaters in Sustainable Energy Systems

- Optimizing Space and Comfort: The Benefits of Ribbed Tubular Heaters for Efficient Heating Solutions

- FAQS

- Conclusion

- Related Posts

You know, as more and more industries look for better ways to manage heat efficiently,

the Finned Tube Heater has really become a game-changer

in a bunch of applications. Over here at Jiangsu Weineng Electric,

we’re pretty proud of staying ahead when it comes to innovation—specializing in designing and making

explosion-proof electric heaters. With years of experience under our belt, we get the ups and downs

that come with thermal tech—it's a constant learning process. In this blog, I want to share what’s coming next

for Finned Tube Heaters, highlighting some cool innovations and the problems they’re actually trying to solve.

By diving into these new advances, I hope to show how they can really boost efficiency and safety in industrial settings.

Ultimately, we see ourselves as part of this exciting evolution in thermal technology and are eager to lead the charge.

You know, as more and more industries look for better ways to manage heat efficiently,

the Finned Tube Heater has really become a game-changer

in a bunch of applications. Over here at Jiangsu Weineng Electric,

we’re pretty proud of staying ahead when it comes to innovation—specializing in designing and making

explosion-proof electric heaters. With years of experience under our belt, we get the ups and downs

that come with thermal tech—it's a constant learning process. In this blog, I want to share what’s coming next

for Finned Tube Heaters, highlighting some cool innovations and the problems they’re actually trying to solve.

By diving into these new advances, I hope to show how they can really boost efficiency and safety in industrial settings.

Ultimately, we see ourselves as part of this exciting evolution in thermal technology and are eager to lead the charge.

Understanding Finned Tube Heaters: A Comprehensive Overview of Their Design

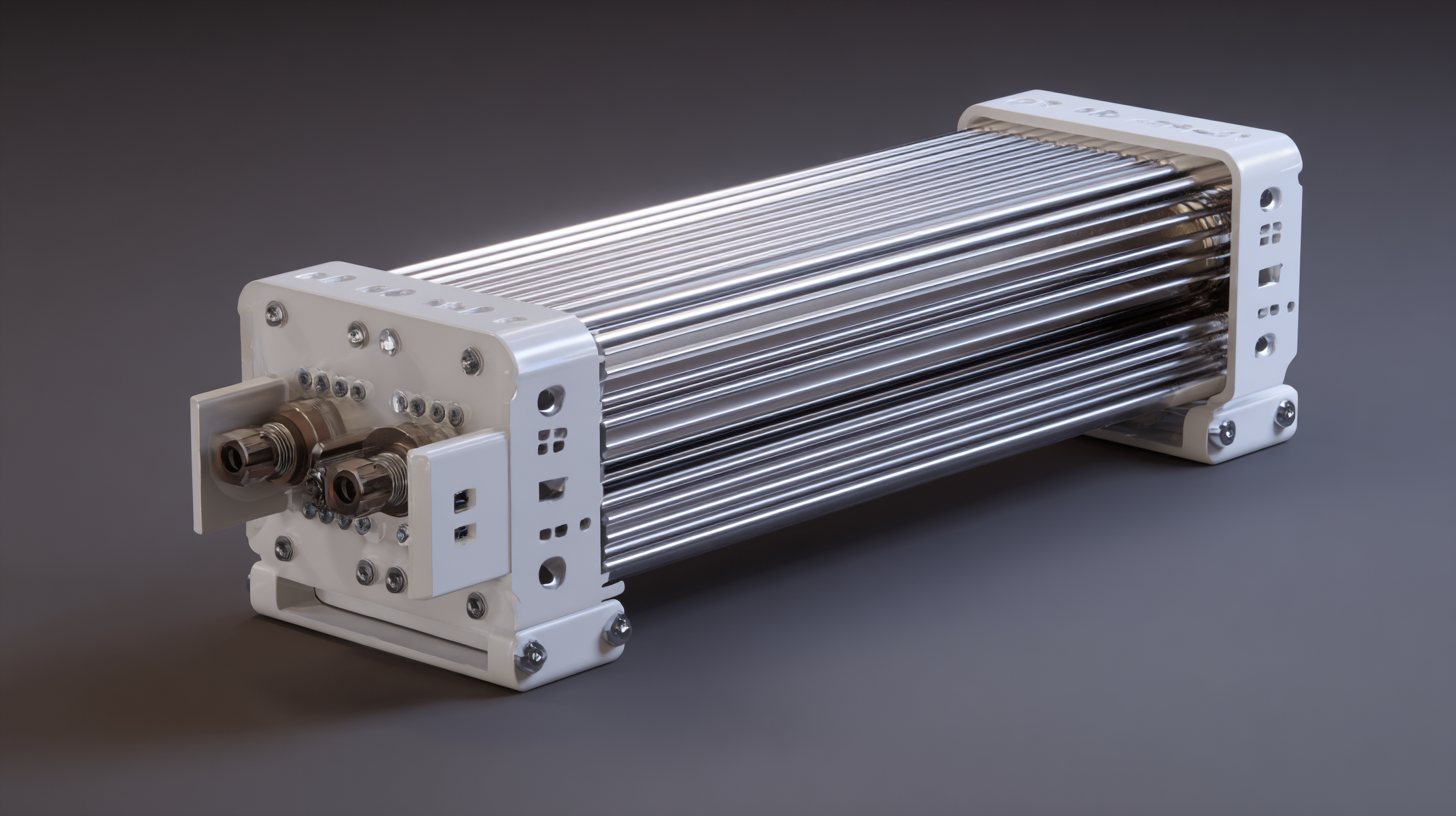

Finned tube heaters have really become a go-to in a lot of industrial setups these days, mainly because they do a great job at boosting heat transfer. The way these heaters are designed is pretty clever — they combine principles from thermodynamics and fluid mechanics to create a compact, space-saving setup that still offers maximum surface area for heat exchange.

According to a report from Global Market Insights, the market for finned tube heaters is expected to keep growing at an annual rate of over 5% through 2026. That just shows how important they’re becoming in energy-efficient systems and all that good stuff.

Finned tube heaters have really become a go-to in a lot of industrial setups these days, mainly because they do a great job at boosting heat transfer. The way these heaters are designed is pretty clever — they combine principles from thermodynamics and fluid mechanics to create a compact, space-saving setup that still offers maximum surface area for heat exchange.

According to a report from Global Market Insights, the market for finned tube heaters is expected to keep growing at an annual rate of over 5% through 2026. That just shows how important they’re becoming in energy-efficient systems and all that good stuff.

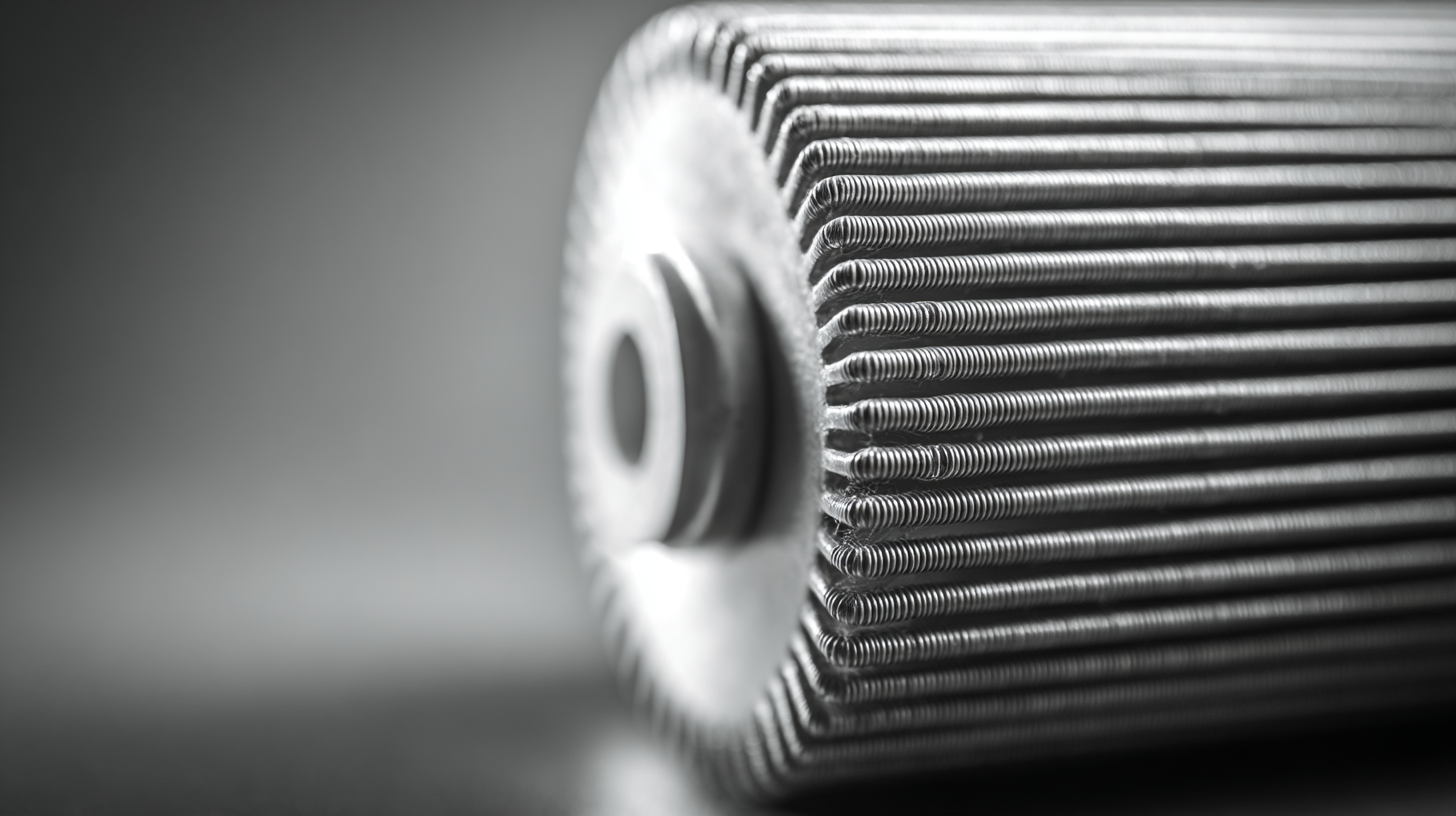

And it’s not just about the basic design anymore — recent innovations in fin shapes, new materials, and manufacturing methods have made these heaters even better. For example, using materials like stainless steel and other corrosion-resistant alloys means they last longer and stay reliable even under really high temperatures. Plus, with the help of computational fluid dynamics (CFD) simulations, engineers can tweak fin configurations to get even better heat transfer. A report from Transparency Market Research mentions that some of the latest smart finned tube designs could save over 20% in energy — pretty impressive, right? It just goes to show how tech keeps pushing thermal management to the next level.

Innovative Materials Enhancing Efficiency in Finned Tube Heater Performance

You know, the progress in finned tube heaters really hinges on new materials that boost how well they work and last. Old-school designs usually used standard metals and alloys, but lately, there have been some pretty cool breakthroughs with advanced composites and coated materials. These new materials help heat transfer better and resist corrosion, which means the heaters last longer and need less maintenance — definitely a win for anyone looking for a more sustainable solution across different industries.

And get this — nanotechnology is starting to make a huge splash in this field too. By adding tiny nanoparticles into the heating elements and fins, these heaters can transfer heat way more efficiently than ever before. The result? Faster heating and lower energy use — pretty critical given how much we’re all trying to be more eco-friendly these days. As industries keep pushing for better, more efficient setups, these innovative materials are definitely leading the charge and shaping what’s next for thermal technology.

The Future of Finned Tube Heaters: Performance Metrics of Innovative Materials

The Role of Smart Technology in Modern Finned Tube Heater Solutions

Hey, have you noticed how smart technology is really changing the game for modern finned tube heaters? I mean, thanks to the Internet of Things, these heaters now do way more than just heat up a space—they can actually monitor things in real-time and even let you control them from your phone. It’s pretty awesome because you can tweak your heating based on how you're actually using it, saving energy and keeping everything comfy. The smart sensors can pick up on temperature changes and automatically adjust the heating, so you're not wasting energy on unnecessary heat — all while staying cozy.

And get this—most of these heaters come with connectivity features that let you manage everything remotely through apps. So, whether you want to schedule a temperature boost before you get home, get notified if something needs attention, or even integrate it into your whole smart home setup, it’s all possible. By bringing in this tech, manufacturers aren’t just making these heaters better—they’re offering personalized solutions that really suit different spaces, whether it's your house or a big industrial site. Honestly, the future looks bright for finned tube heaters—it's all about combining tech and efficiency to make them more adaptable and user-friendly than ever before.

Energy Saving Potential of Finned Tube Heaters in Industrial Applications

You know, these days, there’s a real push for energy efficiency in industrial settings, and finned tube heaters are playing a big part in that. They’re great at transferring heat more effectively, which not only saves energy but also helps cut down costs — a big deal given how much everyone cares about both their wallets and the environment. Recently, there’s been some pretty cool innovations, like rotary steam coil air pre-heaters, which are basically ways to squeeze more performance out of thermal tech — especially in fossil-fuel power plants. By pre-heating the air used for combustion, these heaters make everything more efficient, helping to use less fuel and cut down emissions at the same time.

And it doesn’t stop there. New stuff like phase change materials (or PCM, for short) and thermal energy storage systems are changing the game when it comes to heat management. Integrating PCM into heating setups can really boost how well finned tube systems work — keeping heat better and making sure energy isn’t wasted. As industries keep pushing toward more sustainable options, mixing finned tube heaters with some of these innovative techs, like desiccant-coated energy exchangers and smarter heat exchanger designs, is going to open up a lot more possibilities for saving energy and creating a greener future in thermal technology.

Future Trends: Integration of Finned Tube Heaters in Sustainable Energy Systems

So, you know how finned tube heaters are becoming a big deal in the world of sustainable energy? Well, it looks like their popularity is only going to grow — we're talking about a projected growth rate of around 6.5% each year from 2023 to 2030. The reason? People are really on the hunt for more energy-efficient heating options. These heaters are pretty awesome because they transfer heat so effectively, which makes them super useful for all kinds of stuff — from industrial processes to heating up buildings. Basically, they’re pretty much essential if we want to hit our sustainability targets.

As industries start shifting toward greener tech, it’s clear that finned tube heating systems are becoming a pretty strategic focus. According to a study by the International Energy Agency, heating processes eat up about 30% of industrial energy consumption. But the good news? Thanks to advances in materials and design, modern finned tube heaters are now much better at cutting down energy use and emissions. Plus, they’re totally compatible with renewable energy sources like solar and geothermal, which only boosts their role in building an eco-friendlier energy system. All in all, they’re definitely a key piece of the puzzle when it comes to boosting energy efficiency and doing our bit for the environment.

The Future of Finned Tube Heaters: Innovations Shaping Thermal Technology - Future Trends: Integration of Finned Tube Heaters in Sustainable Energy Systems

| Innovation | Description | Impact on Sustainability | Projected Adoption Rate (%) |

|---|---|---|---|

| Nanotechnology Coatings | Development of advanced coatings that enhance thermal efficiency. | Reduces energy consumption and increases heat transfer. | 35% |

| Smart Control Systems | Integration of IoT technology for real-time monitoring and optimization. | Enhances operational efficiency, leading to lower emissions. | 50% |

| Heat Recovery Systems | Systems designed to recover waste heat for reuse in heating applications. | Significantly reduces overall energy requirements. | 45% |

| Improved Materials | Use of higher conductivity materials to enhance thermal performance. | Contributes to energy efficiency and longevity of equipment. | 40% |

| Modular Designs | Flexible designs that can be easily integrated into existing systems. | Facilitates the transition to sustainable technologies. | 30% |

Optimizing Space and Comfort: The Benefits of Ribbed Tubular Heaters for Efficient Heating Solutions

Ribbed tubular heaters are playing a pivotal role in revolutionizing heating solutions, particularly when it comes to optimizing space and comfort. The enhanced design, featuring electro-galvanized steel fins, significantly increases the surface area for heat transfer. This innovation allows for faster heat dispersion into the surrounding air, making ribbed tubular heaters a superior option compared to standard tubular heaters. According to industry reports, increased surface area can improve heat transfer efficiency by up to 30%, making these heaters ideal for applications in confined spaces such as forced air ducts, dryers, and ovens.

The mechanical bonding of continuous fins on ribbed tubular heaters not only ensures exceptional heat transfer, but also mitigates fin vibration at high air velocities. This feature is crucial for maintaining operational stability and prolonging the lifespan of the heating elements. Lower sheath temperatures result from the effective distribution of heat, and studies indicate that this reduction can extend the operational life of these heaters by 25% or more. The combination of efficient heating and durability makes ribbed tubular heaters a smart investment in both residential and industrial settings.

In settings where heating efficiency directly impacts energy costs, ribbed tubular heaters present a compelling solution. Their ability to accommodate higher power levels in compact spaces, paired with reduced surface temperatures, leads to a more comfortable environment while optimizing energy consumption. This alignment with both performance and efficiency not only meets but exceeds the demands of modern heating applications, solidifying ribbed tubular heaters as a preferred choice for efficient heating solutions.

FAQS

: Smart technology enhances thermal efficiency and user experience by enabling real-time monitoring and control, optimizing heating based on usage patterns, and providing automatic adjustments for energy savings.

Users can manage their finned tube heaters through mobile applications, allowing them to schedule heating cycles, receive maintenance alerts, and integrate the heaters into home automation systems.

Finned tube heaters enhance heat transfer and promote energy savings, which are crucial in cost-conscious and environmentally aware environments, especially through innovations like rotary steam coil air pre-heaters.

The integration of PCM into heating systems allows for better thermal management and energy retention, contributing to improved performance and energy efficiency in finned tube technologies.

The market for finned tube heaters is projected to grow due to increasing demand for energy-efficient heating solutions, with a focus on integrating them into sustainable energy systems and reducing emissions.

Finned tube heaters significantly reduce energy consumption and emissions, as nearly 30% of industrial energy is used for heating processes, making them essential for achieving sustainability goals.

Yes, modern finned tube heaters are compatible with renewable energy sources like solar and geothermal, enhancing their viability in sustainable energy systems.

Innovations in materials and design, as well as the integration of smart technology and energy-efficient features, are driving the growth and adaptation of finned tube heating systems.

The global market for finned tube heaters is projected to grow at a CAGR of 6.5% from 2023 to 2030 due to the demand for energy-efficient heating solutions.

Manufacturers improve performance and offer personalized solutions that cater to the specific needs of various environments, enhancing the adaptability and user-friendliness of finned tube heaters.

Conclusion

You know, the world of thermal tech is changing pretty fast, mainly because of cool innovations in Finned Tube Heaters. These days, they're getting way more efficient and even smarter — it’s like they’re upgrading themselves! It’s really important to get what goes into designing these heaters, especially since they use advanced materials that boost performance and help save energy in industrial setups. And with smart tech now getting involved, these heaters aren’t just more effective — they’re also more adaptable to today's energy needs, which is pretty awesome.

By the way, Jiangsu Weineng Electric Co., Ltd. has been specializing in making explosion-proof electric heaters, including top-of-the-line Finned Tube Heaters. So, they’re in a really good spot to lead the charge in this innovative space. Things are heading toward a future where these heaters fit neatly into sustainable energy systems — really highlighting how important they are for better thermal management and energy savings across different industries. Honestly, it’s exciting to see how all this is shaping up!

Related Posts

-

Innovative Solutions for Industrial Heating Challenges in Manufacturing Environments

-

Ultimate Guide to Choosing the Best China Flange Immersion Heater for Your Needs

-

Exploring Unique Features of Industrial Heating Bundles and How to Select the Best Supplier

-

The Essential Ultimate Guide to Choosing the Best Explosion Proof Industrial Heater Suppliers

-

What is the Significance of Best Custom Immersion Heater in Industrial Applications

-

7 Essential Tips to Choose the Right China Industrial Heating Bundle Suppliers

Blog Tags: