Exploring Innovative Alternatives: The Future of the Best Electric Process Heater for Global Buyers

Table of Contents

- Emerging Technologies in Electric Process Heating Solutions

- Key Factors to Consider When Choosing Electric Process Heaters

- Comparative Analysis of Traditional vs. Innovative Electric Process Heaters

- Global Market Trends Shaping the Future of Electric Process Heating

- Sustainability in Electric Process Heating: Innovations and Practices

- Maximizing Efficiency in Thermal Processes with Industrial Flow Heaters: A Comprehensive Guide

- FAQS

- Related Posts

As industries around the world continue chasing energy efficiency and sustainability, demand for Electric Process Heaters is on the rise. A MarketsandMarkets report projects the global electric heater market to reach about USD 8.6 billion by 2025, fueled by stronger energy-saving efforts and rapid tech advancements. Jiangsu Weineng Electric Co., Ltd.—a newer high-tech player specializing in explosion-proof electric heaters—finds itself right at the forefront of this shift. With solid experience in design, production, and commissioning, Weineng is well positioned to offer innovative options that meet the diverse needs of buyers worldwide. In this post, we’ll take a closer look at different types of Electric Process Heaters, highlighting their features, applications, and the future trends that are likely to shape this dynamic market.

Emerging Technologies in Electric Process Heating Solutions

As the global market for heating equipment is poised to grow significantly—projected to reach about $171.75 billion by 2032—the demand for smart, electric process heating solutions is hotter than ever. Emerging technologies are driving this shift, opening the door to advanced solutions that not only meet efficiency targets but also align with broad sustainability goals. In short, these innovations could redefine how industries use electric heating, turning it into a crucial part of the energy transition. Against this backdrop, companies like Jiangsu Weineng Electric Co., Ltd. are helping shape the future of electric process heating. Weineng brings deep expertise in manufacturing explosion-proof electric heaters and is at the forefront of designing and commissioning systems that meet the evolving needs of a wide range of industries. As green electrification picks up steam, leveraging state-of-the-art technology will be essential for businesses looking to boost productivity while shrinking their environmental footprint. The future of electric process heating looks bright, propelled by a steady commitment to innovation and sustainability.

Exploring Innovative Alternatives: The Future of the Best Electric Process Heater for Global Buyers - Emerging Technologies in Electric Process Heating Solutions

| Technology Type | Efficiency (%) | Operating Temperature Range (°C) | Application Areas | Market Availability |

|---|---|---|---|---|

| Induction Heating | 90-95 | 500 - 3000 | Metal Processing, Cooking | Global |

| Infrared Heating | 80-90 | 100 - 600 | Automotive, Plastics | Europe, North America |

| Resistance Heating | 70-85 | 20 - 1000 | Chemical Processing, Oil & Gas | Global |

| Micro Wave Heating | 75-80 | 50 - 200 | Food Processing, Semiconductors | Asia, North America |

| Heat Pump Technology | 300-400 | -10 - 50 | HVAC, Water Heating | Global |

Key Factors to Consider When Choosing Electric Process Heaters

When you're choosing electric process heaters, buyers around the world should keep a few key factors in mind - things that can really swing efficiency and overall cost. A recent industry report from Market Research Future puts the electric heater market at about $5.12 billion by 2025, driven by growing demand for energy-efficient heating across different sectors. One crucial factor to check is the heater's energy efficiency rating; higher efficiency means lower operating costs and lines up with global sustainability goals.

Tip: take a close look at the manufacturer's specifications to make sure the heater meets or even beats industry energy-efficiency standards. A higher efficiency rating can save as much as 30% in energy costs over the heater's lifetime.

Beyond that, you need to understand the specific requirements of your industry to pick the right heater. Think about factors like the temperature range, control systems, and how well it integrates with your existing equipment. In sectors such as oil and gas, where getting heat transfer right is critical, there are specialized heaters built for high-performance processes that can boost productivity.

Tip: it's worth talking to industry experts or running a quick needs assessment to pin down the exact specifications your electric process heater should meet. Taking this proactive approach can lead to meaningful gains in overall process efficiency.

Comparative Analysis of Traditional vs. Innovative Electric Process Heaters

These days, in industrial heating, people keep talking about traditional electric process heaters versus the newer, smarter options. Traditional electric heaters have long been the go-to because they’re reliable and simple, but they often fall short on energy efficiency and flexibility—two factors that matter a lot in today’s environmentally minded market. Many standard designs limit customization, which can mean suboptimal performance when conditions swing.

On the flip side, innovative electric process heaters are pushing the envelope with tech that boosts efficiency and performance. They tend to feature smart controls, efficient heat transfer mechanisms, and sustainable materials. They also play nicely with renewable energy sources, helping to cut the carbon footprint of industrial processes. As companies chase sustainability and cost-effectiveness, shifting toward these modern solutions seems almost inevitable. While comparative analyses show traditional heaters fit certain applications, the long-term gains of innovative systems are paving the way for the future of heating, meeting the changing demands of buyers worldwide.

On the flip side, innovative electric process heaters are pushing the envelope with tech that boosts efficiency and performance. They tend to feature smart controls, efficient heat transfer mechanisms, and sustainable materials. They also play nicely with renewable energy sources, helping to cut the carbon footprint of industrial processes. As companies chase sustainability and cost-effectiveness, shifting toward these modern solutions seems almost inevitable. While comparative analyses show traditional heaters fit certain applications, the long-term gains of innovative systems are paving the way for the future of heating, meeting the changing demands of buyers worldwide.

Global Market Trends Shaping the Future of Electric Process Heating

The global market for electric process heating is changing fast, driven by new ideas and the urgent push for sustainable energy. With energy costs rising and tighter environmental rules, electric process heaters are turning into the go-to solution for efficient heating. Advances in technology are doing two big things: they boost performance and shrink carbon footprints. Key trends are clear: smart tech and IoT are now part of the mix, helping optimize energy use and deliver real-time data so manufacturers can make smarter decisions and run more efficiently. What's more, demand is growing across sectors like food and beverage, chemicals, and pharmaceuticals. Global buyers who want to cut their eco impact are drawn to electric heating solutions that offer precise control and real energy savings. Government initiatives and incentives are backing this shift too. Looking ahead, the future of electric process heating will hinge on how well manufacturers adapt to these trends—delivering innovative solutions that meet industry needs while supporting broader sustainability goals.

Global Trends in Electric Process Heating Technologies

This chart illustrates the various factors influencing the future of electric process heating technology. As global trends evolve, advancements in heating elements and efficiency play a significant role in shaping market dynamics.

Sustainability in Electric Process Heating: Innovations and Practices

Sustainability is becoming a bigger deal in the electric process heating world, and that momentum is fueling real, practical innovation. Companies are cooking up electric process heaters that not only get the job done but also put environmental responsibility front and center. With tech moving forward, manufacturers are now offering heaters that run on renewable energy and squeeze more efficiency out of every watt—so carbon footprints can drop noticeably. If your business is looking to invest in sustainable heating, these breakthroughs present a chance to line up with global sustainability goals while also trimming operating costs.

Tip: When you're choosing an electric process heater, look for models with smart controls and automation features. They can tune energy use to real-time demand, which means you get both efficiency and sustainability in your day-to-day operations.

Beyond leaner designs, many companies are also exploring eco-friendly materials in manufacturing. This shift helps reduce waste and supports a circular economy. Choosing electric process heaters made from recycled or responsibly sourced materials lets buyers contribute even more to sustainability efforts.

Tip: Check the environmental certifications of potential products. Certifications give you a quick read on a product's sustainability credentials and can help you make smarter buying decisions.

Maximizing Efficiency in Thermal Processes with Industrial Flow Heaters: A Comprehensive Guide

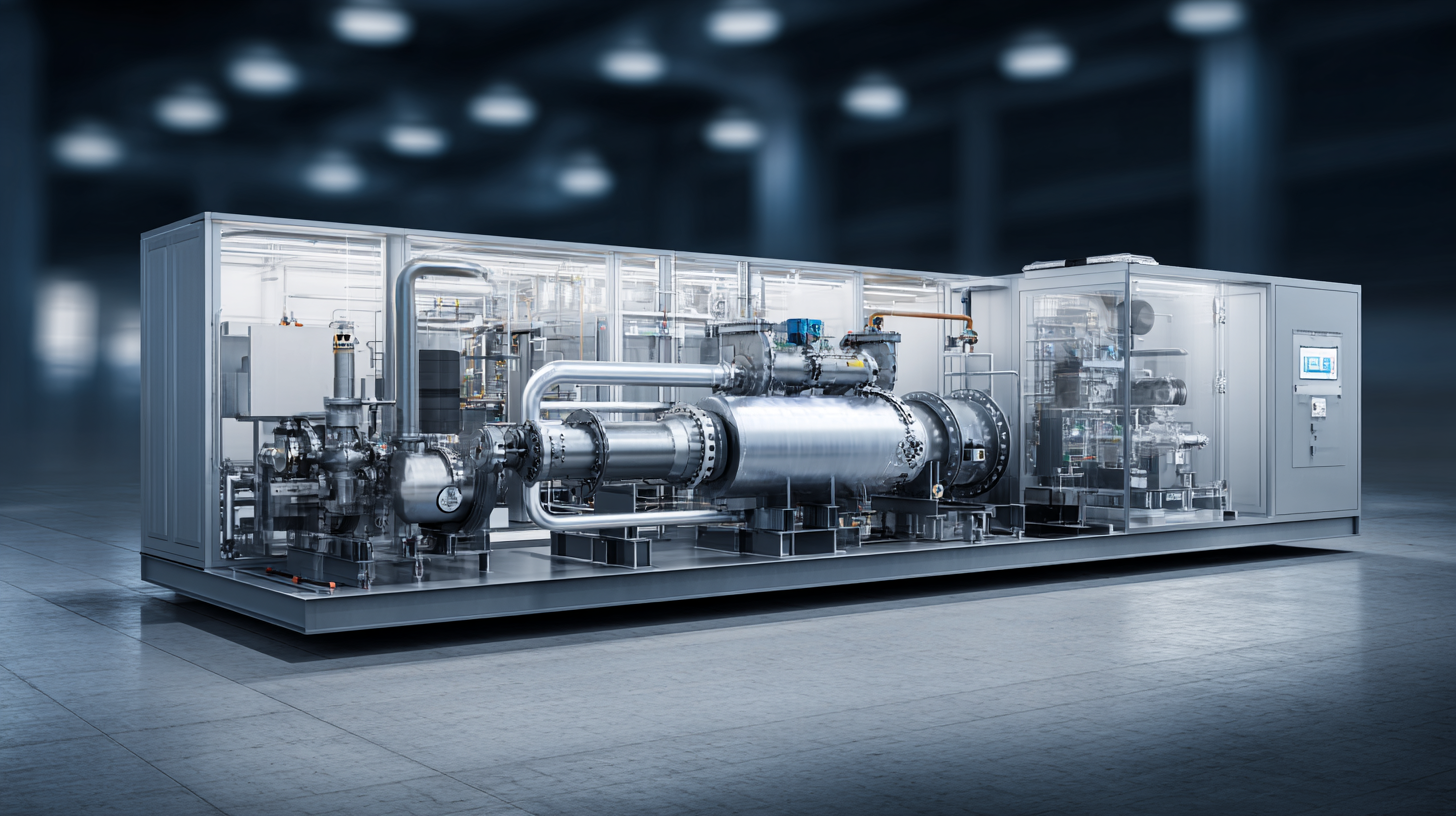

Maximizing efficiency in thermal processes is crucial for industries relying on precise heating solutions. Industrial flow heaters have emerged as a game-changer in this realm, especially for thermal process applications where consistent temperature control is essential. According to a report by Markets and Markets, the industrial heating equipment market is projected to reach $55.66 billion by 2025, driven by the increasing demand for energy-efficient solutions. These heaters are designed to provide rapid heating capabilities while minimizing heat loss, thereby enhancing overall process efficiency.

Utilizing industrial flow heaters can significantly impact production times and product quality. For instance, studies indicate that using flow heaters can reduce heating time by up to 30%, enabling faster turnaround and improved productivity. Moreover, the technology employed in these heaters allows for accurate temperature regulation, ensuring that processes remain within optimal thermal ranges. This precision not only reduces energy consumption but also lowers operational costs, thereby providing a competitive edge in industries such as food processing, chemical manufacturing, and metalworking.

In thermal applications, the integration of industrial flow heaters can also lead to substantial sustainability benefits. According to the International Energy Agency (IEA), industrial processes account for about 36% of global energy consumption. By transitioning to flow heaters that utilize advanced control systems and energy recapture methods, companies can lower their carbon footprints while meeting strict regulatory standards. Investing in such efficient heating solutions is not just a cost-effective strategy; it also aligns with global efforts to promote sustainable industrial practices.

FAQS

: The global heating equipment market is expected to reach $171.75 billion by 2032.

The demand is increasing due to the need for innovative solutions that meet efficiency standards and align with global sustainability goals.

Jiangsu Weineng Electric Co., Ltd. is key in shaping the future of electric process heating by manufacturing explosion-proof electric heaters and designing advanced heating systems for various industries.

Traditional electric heaters are reliable but often lack energy efficiency and flexibility, whereas innovative heaters incorporate advanced technologies that enhance efficiency and performance.

They often feature smart controls, efficient heat transfer mechanisms, and sustainable materials, allowing for better integration with renewable energy.

The shift is influenced by the increasing focus on sustainability and cost-effectiveness within industries, as well as the need for energy-efficient options.

Yes, innovative systems can better integrate with renewable energy sources, helping to reduce the carbon footprint of industrial operations.

Customization and flexibility are essential to optimize performance in varying operational settings and to meet specific industrial needs effectively.

Modern solutions offer long-term benefits such as improved efficiency, sustainable practices, and better alignment with environmental goals compared to traditional options.

Emerging technologies are driving innovation that enhances efficiency, sustainability, and productivity, making electric process heating a crucial part of the energy transition.

Blog Tags: