Mastering Scr Electric Heat Control: A Comprehensive Guide to Optimize Your Industrial Heating Systems

Table of Contents

- Understanding SCR Electric Heat Control: Features and Benefits

- Comparative Analysis of SCR Control Systems vs. Traditional Heating Methods

- Evaluating Efficiency: SCR Electric Heat Control vs. Other Heating Technologies

- Cost-Benefit Comparison: Long-Term Savings with SCR Electric Heat Control

- Case Studies: Successful Applications of SCR Electric Heat Control in Industries

- Future Trends: Advancements in SCR Electric Heat Control for Industrial Use

- Maximizing Safety and Efficiency: The Role of Industrial Electric Heater Control Cabinets in Safe Areas

- FAQS

- Conclusion

- Related Posts

In today's world of industry, making sure your heating systems run smoothly isn't just about keeping things warm—it's about being efficient and safe, especially when dealing with energy-hungry processes.

One game-changing tech that’s really making waves is SCR Electric Heat Control. It offers precise control over temperature and energy use, which is a total lifesaver in lots of applications.

Jiangsu Weineng Electric Co., Ltd. is a standout here; they’re a high-tech company with tons of experience in making explosion-proof electric heaters, handling everything from design to production to setup.

In this guide, we’ll take a closer look at SCR Electric Heat Control—breaking down how it works, sharing some real-world examples, and showing you how industries can leverage it to boost their heating systems.

Not only can it help keep operations running like clockwork, but it also ensures safety standards are met.

So, join us as we explore how really understanding this tech can lead to big improvements in system performance and energy savings.

One game-changing tech that’s really making waves is SCR Electric Heat Control. It offers precise control over temperature and energy use, which is a total lifesaver in lots of applications.

Jiangsu Weineng Electric Co., Ltd. is a standout here; they’re a high-tech company with tons of experience in making explosion-proof electric heaters, handling everything from design to production to setup.

In this guide, we’ll take a closer look at SCR Electric Heat Control—breaking down how it works, sharing some real-world examples, and showing you how industries can leverage it to boost their heating systems.

Not only can it help keep operations running like clockwork, but it also ensures safety standards are met.

So, join us as we explore how really understanding this tech can lead to big improvements in system performance and energy savings.

Understanding SCR Electric Heat Control: Features and Benefits

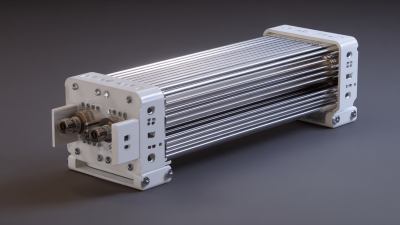

The SCR electric heat control system is pretty impressive tech that's really designed to boost how efficiently and effectively industrial heating setups work. One of the coolest features? Accurate temperature control — it keeps everything running just right, making sure processes stay at peak performance without wasting energy. Plus, thanks to the SCR tech, the system responds quickly when load demands change, which is a big plus in industries where heating needs can vary a lot from one moment to the next.

If your organization’s thinking about jumping into SCR systems, my advice? Take some time to really assess what your heating needs are. Getting that right means you’ll get the most out of the system. And don't forget—regular check-ups and keeping an eye on things can make a huge difference. It’ll keep everything running smoothly and help you save on energy costs in the long run.

But here’s the thing—adopting SCR tech isn’t just about saving energy. It also makes your operation safer by cutting down the chances of overheating, leading to a more stable and reliable environment. It’s a good idea to train your staff on how to operate and maintain these systems properly. That way, you'll get the most bang for your buck and make sure everything integrates smoothly with what you already have going on.

Comparative Analysis of SCR Control Systems vs. Traditional Heating Methods

In the fast-changing world of industrial heating, choosing between SCR (Silicon Controlled Rectifier) control systems and the more traditional methods is pretty important if you want things to run efficiently and safely. You see, old-school methods often rely on direct current or resistive heating, but these can waste energy and often don't keep the temperature as steady as we'd like. On the other hand, SCR control systems offer much more precise temperature control and can actually save energy by tweaking the power input on the fly. This helps cut down on wasted energy and keeps the whole process running smoothly.

At Jiangsu Weineng Electric Co., Ltd., we’ve got years of hands-on experience designing and making explosion-proof electric heaters. So, we're excited to bring our clients some of the latest SCR control solutions. When we incorporate SCR tech into our heating systems, it’s a win-win—industries see big energy savings, and they also stay in line with tough safety standards. The cool thing about SCR systems is how quickly they can respond to changing operational needs, making them way better than traditional methods for keeping everything running just right, across different industrial setups.

Evaluating Efficiency: SCR Electric Heat Control vs. Other Heating Technologies

When it comes to industrial heating systems, hopping on the efficiency train is pretty much a must if you want to get the best performance without breaking the bank. SCR (that’s Silicon Controlled Rectifier, if you’re wondering) electric heat control tech really shines when you compare it to the usual resistive heaters or combustion-based setups. Based on a report from the U.S. Department of Energy, using SCR can boost energy efficiency by up to 30% in certain cases, mainly because it offers much more precise temperature control and cuts down on wasted energy. This isn’t just good for your bottom line — it also helps cut down environmental impact, which is kind of a big deal these days with everyone talking about sustainability.

Now, Jiangsu Weineng Electric Co., Ltd. is honestly leading the way here with their advanced explosion-proof electric heaters. They’ve got tons of experience in designing, building, and installing these systems, and they’ve really harnessed SCR tech to make their heaters perform better. From what industry studies show, adding SCR control can make heating up to 50% faster—meaning you can get your processes running smoother and quicker. As more manufacturers look for smarter, more efficient ways to heat their operations, jumping on the SCR bandwagon seems like a smart move—it's safe, efficient, and reliable, all rolled into one.

Cost-Benefit Comparison: Long-Term Savings with SCR Electric Heat Control

You know, these days, more and more industries are jumping on the bandwagon with SCR (Silicon Controlled Rectifier) electric heat control systems. Honestly, it's a pretty big deal, especially when folks look at the long-term savings compared to the old-school heating methods. I came across a report from the U.S. Department of Energy that said nearly 30% of all energy used in industries goes into heating stuff—so, no surprise, businesses are looking for smarter, more efficient options. The cool part? SCR tech can boost energy efficiency by anywhere from 10% up to 30%, depending on how it’s set up. Basically, by carefully managing how power gets to the heating elements, these systems cut down waste and give you better control over your processes.

Then I read a study from the Electric Power Research Institute (EPRI), and it really highlights the long-term savings potential. They pointed out that companies swapping over to SCR-controlled heating could see a pretty quick return on their investment—like within 3 to 5 years—mainly because they’ll save on energy bills and spend less on maintenance. Over the life of the equipment, these savings really add up, especially for energy-heavy industries like manufacturing and food processing. As more organizations start focusing on being eco-friendly while also saving money, SCR electric heat control is looking like a smart, future-proof move that benefits both the wallet and the planet.

Case Studies: Successful Applications of SCR Electric Heat Control in Industries

Lately, using SCR electric heat control has really turned things around in heating systems across lots of different industries. For example, there’s this pretty interesting case with a big chemical plant that decided to add SCR tech to get better control over their heat processes. According to the International Energy Agency, companies that switched to SCR are seeing energy savings of up to 30% compared to the old-school methods. That’s a pretty huge deal—not only does it cut down on operating costs, but it also helps the environment a lot, which is a win-win considering all the sustainability targets these days.

And it’s not just chemicals—another good example is in food processing. They brought in SCR electric heating to make pasteurization more efficient. What’s cool is that with more precise temperature control, they managed to boost their production efficiency by around 20%, all while keeping their product quality on point. A study by the American Society of Mechanical Engineers highlights that industries using SCR controls usually see a quick return on their investment thanks to these improvements. Overall, shifting to these advanced electric heating solutions is a smart move—it's like a proactive step toward tackling heating challenges head-on, plus it keeps companies competitive in a market that’s always evolving.

Future Trends: Advancements in SCR Electric Heat Control for Industrial Use

You know, the industrial heating world is really going through some big changes these days, mainly because of cool advancements in SCR (Silicon Controlled Rectifier) electric heat control systems. As everyone is super focused on saving energy these days, manufacturers are increasingly turning to SCR tech to make things more reliable and easier to control. A recent report from MarketsandMarkets even says that the global market for SCR tech could hit around USD 7.29 billion by 2027, growing at roughly 6.9% annually. It’s all driven by the need for better temperature management and lower operating costs—pretty crucial in today’s world.

Looking ahead, it seems like smart tech and IoT (that’s the Internet of Things) are going to totally change how SCR electric heating works in industries. A study published in the Journal of Industrial Technology mentioned that companies who have actually adopted smart SCR systems saw up to 30% less energy use. These systems are pretty nifty—they let you monitor and tweak things in real-time, helping industries optimize their heating needs and cut down on waste. As all these innovations keep rolling out, it’s more important than ever for industries to jump on board with the latest SCR solutions if they want to stay competitive in this energy-conscious landscape.

Mastering SCR Electric Heat Control: A Comprehensive Guide to Optimize Your Industrial Heating Systems - Future Trends: Advancements in SCR Electric Heat Control for Industrial Use

| Dimension | Current Trends | Future Advancements | Expected Benefits |

|---|---|---|---|

| Energy Efficiency | Increasing focus on reducing energy consumption and costs. | Integration of smart technologies for real-time monitoring. | Reduced operational costs and improved sustainability. |

| Temperature Control | Adoption of precision temperature management systems. | Development of predictive algorithms for temperature stability. | Enhanced product quality and reduced material waste. |

| Safety Standards | Regulatory developments promoting safer electrical heating solutions. | Innovations to further increase system safety and reliability. | Lower risk of accidents and compliance with regulations. |

| System Integration | Growth of integrated heating systems with IoT capabilities. | Future systems to allow seamless interoperability between equipment. | Improved overall operational efficiency and control. |

| Sustainability | Emphasis on reducing carbon footprint through energy-efficient designs. | Adopting renewable energy sources for heating applications. | Contributing to corporate sustainability goals and enhanced brand image. |

Maximizing Safety and Efficiency: The Role of Industrial Electric Heater Control Cabinets in Safe Areas

In today's industrial landscape, maximizing safety and efficiency in manufacturing processes is paramount. Industrial electric heater control cabinets play a crucial role in ensuring these objectives are met, especially in designated safe areas. By utilizing advanced electrical control panels, manufacturers can achieve higher-level monitoring and control of production machinery. According to a report by MarketsandMarkets, the global market for industrial control systems is projected to reach $25 billion by 2025, underlining the significant reliance on sophisticated control solutions in various sectors.

These control cabinets not only streamline operations but also enhance safety by providing precise monitoring of temperature and operational parameters. With built-in redundancies and fail-safes, they help prevent overheating and other hazardous conditions. The National Fire Protection Association (NFPA) states that inadequate control measures contribute to a significant percentage of industrial accidents. Therefore, implementing robust control systems is essential for mitigating risks and ensuring compliance with safety standards.

Furthermore, the integration of smart technologies in control cabinets allows for real-time data analysis and predictive maintenance, which contributes to operational efficiency. A study from the International Society of Automation highlights that organizations adopting advanced control systems can reduce downtime by up to 30%. This not only leads to increased productivity but also optimizes resource allocation, allowing manufacturers to meet production goals effectively while maintaining a safe working environment.

FAQS

: SCR (Silicon Controlled Rectifier) electric heat control is an advanced technology designed to enhance the efficiency and performance of industrial heating systems, featuring precise temperature regulation and rapid response to load demand changes.

SCR technology can improve energy efficiency by up to 30% in certain applications through precise temperature control and reduced energy losses, contributing to lower operational costs and minimizing environmental impact.

Benefits include improved energy efficiency, safety through reduced risk of overheating, better temperature regulation, and potential productivity increases in industrial operations.

SCR technology offers advantages over traditional methods like resistive heating and combustion systems, including enhanced efficiency, reduced energy consumption, and faster heating times—up to 50% faster in some applications.

Regular maintenance and monitoring of SCR systems enhance their overall performance and reliability, leading to long-term energy savings and optimized operations.

Yes, facilities using SCR systems have reported energy savings of up to 30%, which translates to lower operational costs and a rapid return on investment due to improved efficiency.

Various sectors, including chemical manufacturing and food processing, can benefit from SCR electric heat control by optimizing processes like thermal control and pasteurization.

Yes, training staff on SCR operations is recommended to fully leverage the technology’s potential and ensure smooth integration into existing industrial systems.

The implementation of SCR technology, as shown in case studies, has resulted in significant increases in production efficiency, with examples reporting improvements of around 20%.

By reducing energy consumption and operational costs, SCR technology contributes to sustainability objectives and minimizes the environmental impact of industrial heating processes.

Conclusion

Looking to make industrial heating systems better? Well, 'SCR Electric Heat Control' is definitely making waves lately. I’ve put together this handy guide to walk you through what makes SCR technology tick and why it’s a step up from the old-school methods. Once you dig into it, you’ll see that it’s not just about cool tech—there are real benefits like improved efficiency, cost savings in the long run, and overall better performance. Trust me, when you compare it to traditional systems, the difference is pretty clear.

Plus, I’ve included some real-world examples from different industries, showing how SCR Electric Heat Control actually works in practice and the tangible perks it offers. As a company that’s always looking ahead, Jiangsu Weineng Electric Co., Ltd. really gets these advancements. They’re positioning themselves as leaders in heating solutions right now, pushing for more efficiency and safer industrial operations. It’s pretty exciting stuff if you ask me!

Related Posts

-

The Ultimate Guide to Scr Control for Electric Heaters: Boosting Efficiency with Industry Insights

-

Exploring Innovative Alternatives: The Future of the Best Electric Process Heater for Global Buyers

-

Innovative Solutions for Industrial Heating Challenges in Manufacturing Environments

-

Advantages of Choosing Customized Industrial Heater Manufacturers for Your Business Needs

-

The Future of Finned Tube Heaters: Innovations Shaping Thermal Technology

-

Ultimate Guide to Choosing the Best China Flange Immersion Heater for Your Needs

Blog Tags: