Maximize Efficiency and Safety with Advanced Industrial Duct Heaters in Modern Manufacturing

Table of Contents

- Innovative Technologies Driving Efficiency in Industrial Duct Heaters

- Key Safety Features to Consider for Modern Manufacturing Environments

- Comparative Analysis of Traditional vs. Advanced Duct Heating Solutions

- Energy Consumption and Cost Savings with Modern Duct Heating Systems

- Integrating Smart Controls for Enhanced Duct Heater Performance

- Maintenance Best Practices for Long-Lasting Industrial Duct Heaters

- Comprehensive Guide to Choosing the Right Industrial Duct Heaters for Optimal Performance and Efficiency

- FAQS

- Conclusion

- Related Posts

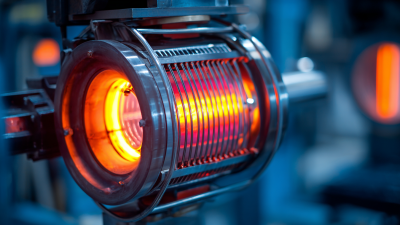

In today’s manufacturing world, making processes efficient and safe is a big deal. One thing that’s really been getting a lot of attention lately is Industrial Duct Heaters. These little guys are pretty crucial—they help keep the right temperatures in factories and industrial spaces. According to a report from the North American Industrial Heating Equipment Association (NAIHEA), using more advanced heating tech can boost energy efficiency by up to 30%. That’s a huge deal because it can lead to some serious savings on costs. And let’s face it, energy costs are a big chunk of what it takes to keep things running smoothly.

Industry expert Dr. Michael Harris from Thermal Innovations puts it simply: “Using better Industrial Duct Heaters doesn’t just make things run smoother; it also makes the workplace safer by keeping temperatures steady.” As manufacturing gets more complicated, having reliable heating systems isn’t just nice to have—it’s essential for avoiding risks related to fluctuating temperatures.

By embracing the latest tech in Industrial Duct Heaters, manufacturers can strike a good balance between top performance and safety. As factories push for higher productivity, understanding the main benefits and best practices for these heating systems is key to handling the challenges of today’s manufacturing scene.

Innovative Technologies Driving Efficiency in Industrial Duct Heaters

You know, these days in manufacturing, everyone’s really pushing to get things more efficient. That’s actually led to some pretty cool advancements in industrial duct heater tech. As industries look for ways to cut down energy costs while still boosting system performance, new and innovative solutions are constantly popping up. In fact, the market for industrial duct heaters is expected to hit over over USD 2.3 billion by 2024 — and it's still on a solid growth path, growing around 5.1% each year up to 2034. A big part of this growth comes from smart heating systems that help optimize energy use and make operations run more smoothly.

Plus, with the whole push towards decarbonization in these industries, there's been a real push to adopt more advanced heating tech. Recent funding initiatives have backed several successful projects aimed at creating zero-carbon heating solutions. Not only do these help save energy, but they also cut down emissions significantly. As these technologies keep improving, they’re really changing the game for industrial heating, paving the way for more sustainable manufacturing practices — which, honestly, are pretty crucial in today’s eco-conscious world.

Key Safety Features to Consider for Modern Manufacturing Environments

When you're choosing advanced industrial duct heaters for today’s manufacturing setup, safety should really be at the top of your list. One thing you definitely want to look for is over-temperature protection. Basically, these systems will automatically shut down the heater if things get too hot—helping to prevent fires and damage to your equipment. And if the heater has flame failure detection, that’s a big plus, because if the flame flickers out for any reason, the system kicks in quickly to keep everything safe.

Also, don’t overlook the importance of good thermal insulation. High-quality insulation not only keeps things safer by reducing the risk of burns or accidental contact with hot surfaces, but it also saves energy. That’s especially important if you’re trying to run a sustainable, efficient operation. Some of the more advanced models even come with automatic shut-off valves and pressure sensors that catch any malfunctions early, giving you peace of mind that everyone and everything stays protected. Focusing on these safety features isn’t just about compliance; it’s about creating a safer, more reliable environment where your team can work confidently and efficiently.

Comparative Analysis of Traditional vs. Advanced Duct Heating Solutions

When it comes to modern manufacturing, choosing the right heating solutions is a pretty big deal. You see, old-school duct heaters still used in some places can be a real pain — they often don’t heat evenly, end up costing more in energy bills, and even pose safety risks. On the flip side, newer industrial duct heaters are packed with clever designs and better materials that boost performance. These modern systems give you much more precise temperature control, which means heating stays consistent throughout the whole process. Plus, they come with improved safety features that meet today’s standards, helping to keep everyone safe and reduce accidents.

At Jiangsu Weineng Electric Co., Ltd., we’re quite proud of what we do—specializing in making explosion-proof electric heaters customized for industrial needs. We’ve got tons of experience in designing, manufacturing, and commissioning these units, so we’re confident we can deliver solutions that not only meet but often beat industry expectations. By using cutting-edge duct heating tech, we help factories and manufacturing plants run smoother, safer, and more efficiently. Honestly, putting your money into these advanced solutions isn’t just smart — it’s a must for companies looking to stay ahead, innovate, and improve their production game.

Energy Consumption and Cost Savings with Modern Duct Heating Systems

Hey, in today’s manufacturing world, cutting down energy use and saving costs are kind of big deals. That’s where these new industrial duct heating systems really come in handy—they've been a total game-changer. According to a 2022 report from the Department of Energy, these modern heaters can be up to 30% more efficient than the older versions. And honestly, that’s huge—less money on energy bills, plus you’re doing your part for the environment by lowering your carbon footprint. It’s a win-win, helping manufacturers hit their sustainability targets without sacrificing performance.

If you really want to get the most out of these systems, it’s a good idea to stay on top of regular maintenance. Keep them running smoothly so they’re working at their best. Also, investing in programmable thermostats can make a big difference—you can tweak the temperature just right and avoid wasting energy. While you're at it, it’s worth checking how well your ductwork is insulated. Good insulation means less heat escapes, keeping everything cozy and making the system more effective.

And here’s a cool tip—adding some smart sensors or IoT tech can give you real-time data on energy use. That way, you can see what's going on and make quick adjustments if needed. A study by the Industrial Heating Equipment Association found that companies using these smart systems saw about a 15% drop in energy costs on average. It’s all about being smarter with your setup. Embracing these new tech tricks doesn’t just boost your bottom line; it also helps keep manufacturing safer and more efficient overall.

Integrating Smart Controls for Enhanced Duct Heater Performance

Bringing smart controls into the mix with industrial duct heaters really changes the game when it comes to how these systems perform in modern factories. You see, with these tech upgrades, facilities can fine-tune temperature settings on the fly, adjusting in real-time as things change around them. Thanks to data analytics and IoT tech, manufacturers can now keep an eye on their duct heaters remotely and tweak their settings without even being on-site. This means energy is used more efficiently, matching what’s actually needed pretty closely. It’s a win-win — better heating, less wasted energy, and a step toward more sustainable manufacturing processes.

Plus, these smart controls aren’t just about efficiency; they also come with predictive maintenance features. That’s a fancy way of saying the system can spot potential issues before they turn into big problems. It analyzes performance data to catch stuff that might go wrong, so repairs can be done proactively—saving downtime and improving safety. This approach helps keep things running smoothly and makes the environment safer for everyone. As industries keep evolving, it honestly feels like integrating smart controls with duct heaters is becoming a must-have for smarter, safer, and more efficient manufacturing.

Maintenance Best Practices for Long-Lasting Industrial Duct Heaters

When you're dealing with industrial duct heaters, keeping up with good maintenance habits is really key to making sure they last longer and work efficiently. Doing regular inspections is a must—think of it like catching problems early before they turn into bigger headaches, which can save you quite a bit of downtime. Things like checking for signs of wear, loose fittings, or rust can really pay off in the long run, saving time and money.

**Pro tip:** Try to do a thorough cleaning of your ductwork about twice a year. This simple step helps prevent dust and debris buildup, which can block airflow and slow things down.

Another thing to keep an eye on is how the heaters are running. Monitoring their temperature settings and how much power they're using can really help you tweak things for better performance. If you notice weird temperature spikes or anything out of the ordinary, it's best to jump on it quickly so you avoid costly repairs later on.

**Another tip:** Look into more advanced monitoring systems that give you real-time updates on how your heater's doing. This way, you can make quick adjustments and keep everything running smoothly.

If you stick to these best practices regularly, you'll likely extend the life of your duct heaters significantly. Plus, it helps keep your production line running safely and efficiently. Basically, making preventive maintenance a routine thing not only boosts performance but also creates a safer work environment overall.

Comprehensive Guide to Choosing the Right Industrial Duct Heaters for Optimal Performance and Efficiency

When it comes to optimizing performance and efficiency in various industrial settings, selecting the right duct heater is essential. A duct heater serves a critical role in heating the air that flows through air ducts, ensuring that the environment remains conducive for operations. With various shapes available—such as square, round, and coiled—these heaters are designed to seamlessly integrate into an array of HVAC and industrial duct systems. This versatility means that businesses can choose duct heaters tailored specifically to their needs, contributing to both energy savings and enhanced operational efficiency.

In order to make an informed decision, it's vital to consider the specific requirements of your system. Factors such as the size of the ducts, the volume of air to be heated, and the desired temperature rise will all influence the selection process. Square duct heaters, for instance, may be ideal for standard rectangular duct systems, while round or coiled options can be more effective in tight spaces or specialized applications. Understanding these elements will not only improve performance but also boost energy efficiency, reducing operational costs in the long run. With the right duct heater, industries can ensure optimal air temperatures are maintained, leading to improved productivity and workplace comfort.

FAQS

: The main advancements include the integration of smart heating systems that optimize energy consumption and improve operational efficiencies, along with a focus on decarbonization.

The duct industrial heater market is projected to surpass USD 2.3 billion by 2024, with a compound annual growth rate of 5.1% through 2034.

Modern duct heating systems can achieve up to 30% greater efficiency compared to older models, resulting in lower operational costs and a reduced carbon footprint.

Manufacturers can maximize benefits by performing regular maintenance, investing in programmable thermostats, and ensuring proper insulation of ductwork.

Advanced sensors and IoT technology provide real-time data that enable manufacturers to monitor energy use and adjust operations, leading to an average energy cost reduction of 15%.

Smart controls optimize temperature regulation by adapting to operational demands in real time, allow for remote monitoring and adjustments, and help minimize energy waste.

Predictive maintenance features allow for proactive repairs by identifying potential issues before they escalate, thus reducing downtime and enhancing safety in the manufacturing environment.

Energy efficiency is crucial for reducing costs, minimizing carbon footprints, and meeting sustainability goals, which are essential in today’s environmentally conscious market.

Integrating smart heating systems enhances profitability by improving energy efficiency and aligns energy consumption with actual operational needs, contributing to sustainable manufacturing practices.

Advanced technologies, such as predictive maintenance through smart controls, help prevent hazardous situations by ensuring operational integrity and safety in manufacturing processes.

Conclusion

In today's manufacturing world, getting the balance right between efficiency and safety is more important than ever. That’s where these advanced Industrial Duct Heaters really come into play—they’re crucial for hitting those goals. Thanks to some pretty innovative tech, duct heating is transforming quite a bit. These new systems not only deliver better performance but also pack important safety features, which are a must in modern industrial settings. When you compare them to the older, traditional options, it’s clear they stand out—saving energy, cutting costs, and just overall working smarter.

And here’s the cool part: by including smart controls, these heaters aren’t just more efficient—they let you monitor how they’re doing in real-time. That means you can keep an eye on things and make sure they stay in top shape longer. Plus, sticking to good maintenance routines really helps extend their lifespan and keeps everything running smoothly. Take Jiangsu Weineng Electric Co., Ltd., for example; they’re experts in explosion-proof electric heaters. By using the latest tech in designing and building these systems, they’re making industrial environments safer and more reliable overall. It just goes to show—innovating in heating solutions isn’t just about tech, it’s about making workplaces better and safer for everyone.

Related Posts

-

Understanding Industrial Duct Heaters: Essential Insights for Optimal Performance and Efficiency

-

Evaluating the Best Customized Industrial Heater Suppliers: A Comprehensive Comparison Guide

-

How to Choose the Right China Customized Industrial Heater Manufacturers for Your Business Needs

-

How to Choose the Right Industrial Heater Bundle for Your Business Needs

-

How to Maximize Efficiency with China Industrial Heating Bundle Solutions

-

Revolutionizing Heat: How Industrial Oil Heaters Enhance Efficiency in Modern Industries

Blog Tags: