Maximize Efficiency with Flange Immersion Heaters for Industrial Applications

Table of Contents

- Understanding Flange Immersion Heaters and Their Benefits

- Key Factors to Consider When Selecting Flange Immersion Heaters

- Installation Best Practices for Flange Immersion Heaters in Industrial Settings

- Optimizing Heater Performance through Proper Maintenance Techniques

- Troubleshooting Common Issues with Flange Immersion Heaters

- Innovative Applications of Flange Immersion Heaters in Various Industries

- Maximizing Efficiency with Flange Immersion Heaters: Insights from the Latest Market Trends and Industry Reports

- FAQS

- Conclusion

- Related Posts

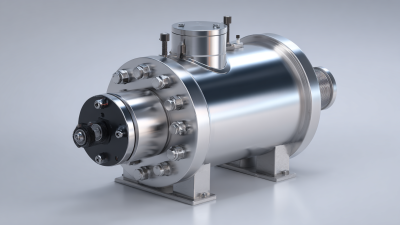

In today’s fast-moving world of industrial stuff, getting things to run smoothly and efficiently is more important than ever. One key player here is the Flange Immersion Heater — it might sound technical, but trust me, it’s pretty essential. Recent industry reports mention that the global market for industrial heaters is expected to hit around USD 6.21 billion by 2026, growing at about 5.2% annually since 2021. That just shows how much folks are craving reliable, energy-efficient heating options.

At Jiangsu Weineng Electric Co., Ltd., a trailblazing high-tech company known for our expertise in explosion-proof electric heaters, we genuinely understand how vital Flange Immersion Heaters are for improving operational performance, safety, and saving costs across different industries. With years of experience in designing, manufacturing, and setting these heaters up, we’re all about crafting smart solutions that fit each client’s unique heating needs — helping them perform at their best, even in the toughest environments.

At Jiangsu Weineng Electric Co., Ltd., a trailblazing high-tech company known for our expertise in explosion-proof electric heaters, we genuinely understand how vital Flange Immersion Heaters are for improving operational performance, safety, and saving costs across different industries. With years of experience in designing, manufacturing, and setting these heaters up, we’re all about crafting smart solutions that fit each client’s unique heating needs — helping them perform at their best, even in the toughest environments.

Understanding Flange Immersion Heaters and Their Benefits

You know, flange immersion heaters are really gaining popularity in industrial settings these days. Why? Well, they’re super effective at improving efficiency and cutting down operational costs. Basically, they’re designed to be immersed directly into liquids, giving you precise control over the heating process. That makes them perfect for a bunch of different industries, from chemical manufacturing to food production. And according to industry reports, switching to electric immersion heaters can boost energy efficiency by up to 30% compared to the old-school steam systems. That’s a big deal when it comes to saving on energy bills!

One of the best parts about flange immersion heaters? They’re pretty easy to install and maintain. Plus, you can customize them to fit your specific needs, so they slide right into your existing setup without a hassle. Their quick heating feature also helps reduce downtime — which, trust me, is a lifesaver in industrial environments. To get the most out of them, I’d recommend setting up a regular maintenance routine and using temperature controls. That way, you can really optimize energy use.

Pro tip: Make sure you size the heater correctly for your particular application — no point in wasting energy. Keep an eye on cleaning and inspecting the components regularly; it’ll help keep things running smoothly and extend the lifespan of your equipment. Lastly, consider investing in programmable controls—they can really level up your efficiency by adjusting to changing process needs on the fly.

Key Factors to Consider When Selecting Flange Immersion Heaters

When you're choosing flange immersion heaters for industrial use, there are quite a few things you'll want to keep in mind to make sure they work efficiently and get the job done right. First off, material compatibility is a big deal. You want to pick a heater that gets along well with the fluid you're heating — whether it's water, oil, or something more corrosive. According to the *2022 Industrial Heating Report*, picking the right material isn’t just about stopping corrosion; it also helps the heat transfer process, which can actually cut energy costs by up to 30%. Usually, stainless steel works great for water and some oils, but if you're dealing with more aggressive fluids, you'll probably need specialized alloys.

Another key thing is to figure out the wattage and heating capacity your process needs. Industrial setups often demand tight temperature control, and using the correct wattage makes a huge difference in how efficiently everything runs. A recent study from the *American Society of Mechanical Engineers (ASME)* mentioned that if wattage is off, you could end up wasting around 15-20% of energy—nothing to sneer at! Plus, features like adjustable thermostats and good insulation can really boost efficiency, saving you money in the long run and keeping your system running smoothly. Get these choices right, and you’ll be set to keep your operations running at their best with these heaters doing their thing.

Maximize Efficiency with Flange Immersion Heaters for Industrial Applications

This chart represents the efficiency levels of various flange immersion heaters across different temperature settings in industrial applications. The data illustrates how efficiency is impacted by temperature, highlighting the optimal performance range for these heaters.

Installation Best Practices for Flange Immersion Heaters in Industrial Settings

Flange immersion heaters are really gaining recognition for how effectively they can heat fluids in industrial setups. But here’s the thing—proper installation makes all the difference when it comes to getting the most out of these heaters and making them last longer. One of the most important steps is making sure you pick the right size heater for your specific application. If you go too big or too small, it’s a recipe for trouble. Trust me, choosing a unit that matches the volume and type of fluid can make a huge difference in performance. Industry folks say that using the wrong size can waste a ton of energy—up to 30% in some cases—which just ramps up your costs unnecessarily.

And then there’s how you actually set up the heater—orientation and mounting are key. You want to position it so that the heated fluid circulates smoothly around it. When you do that, it boosts thermal efficiency and helps keep the temperature even throughout. Oh, and don’t forget about sealing things up tightly and insulate well—heat escapes easily otherwise, and that’s just money down the drain. In fact, proper sealing can save anywhere from 10% to 20% on energy costs. Bottom line: if you pay attention to the little details during installation, you’ll get way more out of your flange immersion heater—more efficiency, less energy waste, and better overall operation.

Maximize Efficiency with Flange Immersion Heaters for Industrial Applications - Installation Best Practices for Flange Immersion Heaters in Industrial Settings

| Dimension | Value/Description |

|---|---|

| Power Rating | 3 kW to 100 kW |

| Material | Stainless Steel, Incoloy |

| Voltage Options | 120V, 240V, 480V |

| Installation Type | Flanged Mount |

| Temperature Range | Up to 300°C (572°F) |

| Applications | Heating Oil, Water, Chemicals |

| Safety Features | Thermal cut-off, Insulation |

| Maintenance Frequency | Every 6 to 12 months |

Optimizing Heater Performance through Proper Maintenance Techniques

Keeping your flange immersion heaters properly maintained is super important if you want them to work their best in industrial settings. Honestly, just doing regular checks and giving them a good clean now and then can make a huge difference. Over time, you'll probably notice mineral buildup and gunk that can slow down heat transfer — nobody wants that! Setting up a simple routine for maintenance not only helps extend the lifespan of your heaters but also keeps downtime to a minimum, which is a total lifesaver.

A couple of handy tips? Make a habit of inspecting the heater’s surface for any signs of wear or damage. It’s also a good idea to keep a log of your maintenance efforts and how your heaters are performing. That way, you can catch potential issues early before they turn into bigger problems. And don’t forget — always double-check that your heater’s running within the recommended temperature and pressure ranges from the manufacturer. Pushing it outside those limits can cause unnecessary strain.

Here at Jiangsu Weineng Electric Co., Ltd., we’re all about designing robust explosion-proof electric heaters that can handle even the toughest environments. Thanks to our cutting-edge technology and industry know-how, our heaters are built to last and actually help cut down operational costs through boosted efficiency. The key is regular maintenance — it's your best shot at keeping everything running smoothly and supporting a steady growth in this growing market, which is expected to hit around $1.151 billion by 2033.

Troubleshooting Common Issues with Flange Immersion Heaters

Flange immersion heaters are pretty essential in industrial settings—they’re a reliable way to get heat where you need it. That said, like any piece of equipment, they’re not foolproof and can run into problems that mess with your operations. One common issue is if they're not installed properly, which can lead to poor heating performance or, worse, equipment breakdown. So, before firing them up, it’s super important to double-check that they’re mounted correctly and all electrical connections are tight and secure.

When you’re troubleshooting these heaters, keep an eye out for overheating. That can happen if there's scaling caused by water impurities or if the fluid flow isn’t happening as it should. Overheating doesn’t just slow things down—it can actually cause damage to the heater and nearby equipment. Regularly monitoring temperature levels and sticking to routine maintenance is definitely the way to go to keep everything running smoothly.

Quick tips:

- Always follow the manufacturer’s instructions for installation and upkeep—cutting corners is never a good idea.

- Make a habit of inspecting the heating element for any signs of scaling or corrosion, and deal with any issues right away to keep things running efficiently.

- Keep a record of your operation data; if you notice trends over time, it might help you catch potential issues early before they turn into major problems.

Innovative Applications of Flange Immersion Heaters in Various Industries

Flange immersion heaters are pretty essential in a bunch of industrial setups. They’re like the go-to solution for heating liquids in tanks and vessels efficiently. Take the food and beverage industry, for example—they're super important for keeping things at the right temperature during processes like pasteurization or mixing. These heaters spread heat evenly, which not only boosts the quality of the final product but also helps save energy and cut down on operating costs.

On the other hand, in chemical manufacturing, flange immersion heaters are crucial for processes where you really need to control the temperature precisely. They’re built tough enough to handle some pretty harsh environments and can resist corrosive stuff, making them perfect for heating reactants, catalysts, or finished products. Their flexibility means you’ll find them in everything from making plastics to refining oil—anywhere maintaining specific temperatures matters for quality and efficiency. Plus, with new tech advancements, a lot of modern heaters now come with smart controls and monitoring features, which makes them even more versatile and reliable across different industries.

Maximizing Efficiency with Flange Immersion Heaters: Insights from the Latest Market Trends and Industry Reports

Flange immersion heaters are becoming increasingly essential in various industries due to their efficiency in heating liquids, oils, and other viscous fluids directly. Installed within tanks, these heaters provide an effective solution for applications requiring precise temperature control. According to market analysis by the Global Industrial Heating Equipment Report, the immersion heater segment is projected to grow by over 8% in the coming years, driven by rising demand across chemical processing, food and beverage, and water treatment sectors.

One of the key advantages of flange immersion heaters is their direct contact with the fluid, which enhances thermal conductivity and minimizes energy loss. This feature allows for rapid heating, improving overall process efficiency. Industry insights indicate that companies adopting advanced immersion heating technology can reduce operational costs by as much as 20%. Moreover, the ability to seamlessly integrate these heaters into existing systems makes them an appealing choice for many manufacturers looking to upgrade their heating methods without significant infrastructure changes.

Additionally, the versatility of flange immersion heaters is notable; they can be installed using various fittings depending on system requirements. Recent trends indicate an increasing shift towards customizable solutions, allowing businesses to tailor their heating systems for maximum efficiency. As reported by the Heating Technology Association, the focus on sustainability is prompting companies to invest in efficient heating solutions, highlighting the pivotal role of flange immersion heaters in modern industrial applications.

FAQS

: Flange immersion heaters are devices designed for direct immersion in liquids, widely used in industrial applications such as chemical processing and food production for precise heating control.

Flange immersion heaters can improve energy efficiency by up to 30% compared to traditional steam heating systems, leading to significant reductions in energy bills.

Flange immersion heaters are known for their ease of installation and maintenance. They can be customized for specific requirements and require minimal downtime during operation.

Proper sizing ensures that the heater matches the volume and type of fluid being heated, preventing energy waste and reducing operational costs, as improperly sized heaters can lead to up to 30% unnecessary energy expenditure.

Heaters should be positioned to allow optimal circulation of the heated fluid, which improves thermal efficiency and ensures a uniform temperature distribution.

Regularly cleaning and inspecting heater components, implementing a maintenance schedule, and using programmable controls can enhance efficiency and prolong the lifespan of the heaters.

Proper sealing and insulation at the installation site can prevent heat loss and lead to energy savings of 10-20%, emphasizing the importance of detail in the installation process.

Sizing the heater correctly, regularly maintaining and inspecting components, and investing in programmable controls that adapt to process changes can greatly enhance heating efficiency.

Rapid heating capabilities minimize downtime during industrial operations, which is crucial for maintaining productivity and efficiency.

By following best practices for installation and maintenance, industries can leverage flange immersion heaters to ensure efficient operations and reduce overall energy costs.

Conclusion

Flange immersion heaters are pretty much essential in loads of industrial setups. They work by directly immersing their heating elements into liquids, which helps transfer heat pretty efficiently. If you ask me, one of the biggest perks is how they give you pretty accurate control over temperature and help heat things evenly — that’s a real game-changer for keeping operations running smoothly. When you're choosing a flange immersion heater, it’s important to think about things like how much power you need, what materials the heater is made of, and where you'll be installing it. All these factors really matter if you want the heater to perform at its best.

Getting the installation right and sticking to regular maintenance is super important if you want these heaters to last longer and work more efficiently. Doing things the right way during setup can help avoid common headaches later on, and if something does go wrong, understanding how the heater works makes troubleshooting way easier. Plus, these heaters aren’t just for one or two uses — they’re pretty versatile and find all sorts of applications across different industries today. Companies like Jiangsu Weineng Electric Co., Ltd. really shine here, especially with their expertise in making explosion-proof electric heaters, making sure you get reliability and efficiency no matter what industrial needs you’re tackling.

Related Posts

-

Emerging Technologies for Industrial Flange Heater Solutions by 2025

-

The Ultimate Guide to Choosing the Best Industrial Flange Heater Suppliers for Your Needs

-

Exploring Flange Heater Bundle Suppliers Opportunities at the 138th China Import and Export Fair 2025

-

Understanding the Efficiency and Applications of Industrial Electric Heaters in Modern Manufacturing

-

Understanding Industrial Duct Heaters: Essential Insights for Optimal Performance and Efficiency

-

How to Choose the Right China Customized Industrial Heater Manufacturers for Your Business Needs

Blog Tags: