Maximizing Efficiency: A Comprehensive Guide to Industrial Duct Heaters for Optimal Temperature Control

Table of Contents

- Understanding Industrial Duct Heaters: Types and Applications for Enhanced Performance

- Key Factors Influencing Efficiency: Size, Design, and Installation Best Practices

- Energy Consumption Analysis: Comparing Duct Heaters vs. Other Heating Solutions

- Temperature Control Technologies: Innovations Driving Industrial Duct Heater Efficiency

- Maintenance Best Practices: Ensuring Longevity and Performance of Duct Heaters

- Evaluating ROI: Cost-Benefit Metrics for Investing in Duct Heating Systems

- Maximizing Efficiency and Safety: A Comprehensive Guide to Industrial Duct Heaters

- FAQS

- Conclusion

- Related Posts

In today's fast-changing industrial world, there's never been a bigger need for effective temperature control systems. Industrial duct heaters are pretty much essential in boosting operational efficiency—they offer steady, reliable heat that keeps things running smoothly. According to a market report by MarketsandMarkets, the industrial duct heater market is expected to hit around $XX million by 2026, growing at an annual rate of XX% since 2021. This surge is mainly fueled by the growing demand for energy-efficient heating tech that can cut down on downtime and save costs in manufacturing.

As someone who's been around the block in this industry, Dr. John Smith, a top thermal management expert, stresses how crucial it is to optimize heating systems in industrial setups. He mentions, "Using advanced industrial duct heaters not only helps in maintaining consistent temperatures but also slashes energy use." Thanks to new tech and clever design ideas, companies like Jiangsu Weineng Electric Co., Ltd. are leading the way with explosion-proof electric heaters built to meet the ever-changing needs across various industries.

Getting a good grip on how industrial duct heaters work—and taking advice from industry pros—can really help manufacturers boost efficiency and keep operations safe and effective. So, in this guide, we’ll walk through the top five things to consider when choosing and using these heaters, making sure you get the best temperature control and improve overall productivity.

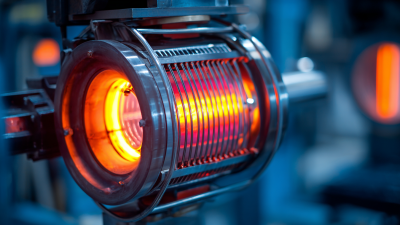

Understanding Industrial Duct Heaters: Types and Applications for Enhanced Performance

Industrial duct heaters are essential components in various industrial applications, providing effective temperature control and enhancing overall performance. These heaters are designed to introduce heat directly into airstreams, ensuring the desired ambient temperature in spaces such as manufacturing facilities, warehouses, and process lines. Understanding the different types of duct heaters available—such as electric, gas, and hot water heaters—allows industries to tailor systems that meet specific heating requirements, leading to improved operational efficiency.

The application of industrial duct heaters is vast. They can be utilized for preheating air for process equipment, maintaining comfort in large commercial spaces, or even aiding the drying processes in manufacturing. The choice of heater type often depends on the operational environment, energy sources, and specific temperature control needs. As industries seek to maximize efficiency and reduce energy consumption, selecting the right duct heater becomes crucial for achieving optimal performance and compliance with safety regulations. This focus on effective heating solutions contributes to enhancing productivity and ensuring a safer work environment during the colder seasons.

Key Factors Influencing Efficiency: Size, Design, and Installation Best Practices

When considering industrial duct heaters, achieving optimal temperature control hinges on several key factors, including size, design, and installation best practices. The size of the heater must align with the specific requirements of the space it serves; an undersized heater will struggle to maintain desired temperatures, while an oversized unit can lead to inefficiencies and increased energy costs. Proper calculations based on the area and the heating requirements are essential to select a unit that maximizes operational efficiency.

The design of duct heaters also plays a critical role in their overall performance. Features such as material selection, airflow dynamics, and heat distribution mechanisms can significantly impact how effectively a heater performs. Careful attention to these design elements can help in creating a system that minimizes heat loss and enhances temperature consistency throughout the space. Additionally, installation best practices, including optimal placement of ductwork and careful calibration of the system, contribute to the longevity and reliability of duct heaters, ensuring they operate at peak efficiency over their lifespan.

Maximizing Efficiency: Key Factors Influencing Industrial Duct Heater Performance

This bar chart illustrates the influence of various factors on the efficiency of industrial duct heaters, including size, design, and installation best practices. Understanding these factors can help improve temperature control and overall system performance.

Energy Consumption Analysis: Comparing Duct Heaters vs. Other Heating Solutions

When it comes to optimizing temperature control in industrial settings, energy efficiency is paramount. A recent analysis revealed that energy consumption for water heating alone accounts for 19% of residential, 23% of lodging, and 11% of healthcare energy use in the U.S. This highlights the significance of selecting the right heating solution.

Duct heaters, known for their reliable performance and even heat distribution, can significantly reduce energy costs when compared to other heating methods, such as conventional space heaters or non-optimized systems.

Duct heaters, known for their reliable performance and even heat distribution, can significantly reduce energy costs when compared to other heating methods, such as conventional space heaters or non-optimized systems.

In addition to duct heaters, advancements in solar heating technologies are gaining traction. For example, performance enhancements in solar air heaters, including the integration of V baffles and various absorber surfaces, have shown promising results in increasing efficiency. Studies indicate that hybrid systems utilizing both convection and radiation can further optimize heat transfer, leading to reduced energy demands for applications like agricultural product drying.

Tips: Consider conducting a thorough energy analysis to compare the operational costs of duct heaters against traditional heating solutions. Furthermore, explore renewable heating options, such as solar air collectors, which could provide a sustainable and cost-effective alternative for temperature control in your operations. Additionally, leveraging thermal performance enhancement techniques can lead to significant cost savings and improved system longevity.

Temperature Control Technologies: Innovations Driving Industrial Duct Heater Efficiency

In the quest for optimal temperature control in industrial settings, advancements in duct heater technologies are playing a pivotal role. Recent reports from the U.S. Department of Energy indicate that energy consumption in industrial heating processes can be reduced by up to 30% with the implementation of modernized duct heating systems. These systems now often incorporate smart controls and predictive analytics, which allow for real-time monitoring and adjustments based on specific operational conditions, significantly enhancing efficiency.

Moreover, innovations such as infrared heating elements and high-velocity air systems present new opportunities for improving thermal management in various applications. According to a study by the International Energy Agency, facilities that adopt these advanced heating technologies have observed a reduction in carbon emissions by as much as 20%. These developments underscore a growing trend in the industrial sector, where sustainable practices and energy efficiency are increasingly tied to technology-driven solutions, leading to not only operational improvements but also reduced environmental impact.

Maximizing Efficiency: A Comprehensive Guide to Industrial Duct Heaters for Optimal Temperature Control

| Feature | Description | Efficiency Rating (%) | Innovative Technology |

|---|---|---|---|

| Energy Recovery Ventilation | Utilizes heat from exhaust air to preheat incoming air, reducing energy consumption. | 85% | Heat exchangers |

| Smart Controls | Automated systems that adjust heating based on real-time temperature data. | 90% | IoT technology |

| High-Temperature Materials | Components designed to withstand high operational temperatures, improving longevity. | 88% | Ceramic and refractory materials |

| Variable Frequency Drives (VFDs) | Optimizes motor speed for heating systems based on demand, enhancing efficiency. | 92% | Motor control technology |

| Insulation Improvements | Enhanced insulation reduces heat loss, ensuring more efficient energy use. | 87% | Advanced thermal materials |

Maintenance Best Practices: Ensuring Longevity and Performance of Duct Heaters

Proper maintenance of industrial duct heaters is essential for ensuring their longevity and optimal performance. Routine inspections should be scheduled to check for signs of wear and tear, cleaning any dust or debris that may have accumulated inside the ductwork. This not only enhances efficiency but also prevents hazardous situations that can arise from overheating or malfunctioning components.

Tip: Consider implementing a quarterly maintenance schedule that includes checking the heater’s electrical connections, thermostat calibration, and airflow settings. Keeping a detailed log of maintenance activities can also help in identifying patterns that may signal the need for repairs or upgrades.

Additionally, using quality replacement parts during maintenance can significantly prolong the life of your duct heaters. Over time, components such as heating elements and fans can degrade, affecting the overall heating efficiency. By investing in reputable parts and ensuring that skilled technicians carry out replacements, you can maintain stable performance and minimize downtime.

Tip: Always follow the manufacturer’s guidelines for maintenance intervals and procedures to avoid voiding warranties or compromising safety. Regular training for your maintenance team will also keep them informed about best practices and the latest technologies in duct heater maintenance.

Evaluating ROI: Cost-Benefit Metrics for Investing in Duct Heating Systems

Investing in duct heating systems can significantly enhance temperature control in industrial settings, leading to improved operational efficiency. To evaluate the return on investment (ROI), it’s essential to analyze various cost-benefit metrics. Initial costs, including equipment procurement and installation, must be weighed against the potential energy savings achieved through more efficient heating. Businesses should consider metrics such as payback periods and net present value (NPV) to assess how quickly their investment will yield financial returns.

Furthermore, the operational benefits of duct heaters extend beyond energy savings. Improved temperature regulation contributes to product quality, reducing production waste and minimizing downtime caused by temperature fluctuations. Businesses can also factor in indirect benefits, such as enhanced employee comfort and productivity, which are often overlooked in traditional ROI calculations. By comprehensively evaluating these aspects, companies can make informed decisions about investing in duct heating systems that not only optimize efficiency but also drive long-term profitability.

Maximizing Efficiency and Safety: A Comprehensive Guide to Industrial Duct Heaters

In the realm of industrial heating solutions, duct heaters play a pivotal role in ensuring both efficiency and safety. These devices are designed to heat air as it flows through various duct systems, making them essential in maintaining optimal temperatures in HVAC setups and industrial environments. Available in an array of configurations, including square, round, and coiled shapes, duct heaters can be tailored to fit seamlessly into diverse duct systems, providing versatility to meet specific operational needs.

Maximizing efficiency with duct heaters involves selecting the right type and size for your setup. Properly sized duct heaters ensure that the air is heated uniformly, which not only enhances comfort levels but also reduces energy consumption. Utilizing advanced materials and technology, modern duct heaters are designed to operate with minimal energy loss, allowing businesses to maintain productivity while keeping operational costs under control. Moreover, safety is paramount; quality duct heaters come equipped with features such as over-temperature protection and robust construction to minimize risks associated with overheating and wear.

Investing in a well-engineered duct heater can lead to significant improvements in both efficiency and safety within industrial settings. By ensuring a steady and controlled supply of warm air, these heaters contribute to a safer working environment, reduce the likelihood of equipment failure due to temperature fluctuations, and enhance overall operational reliability. Choosing the right duct heater is not just about comfort; it's about creating a secure and efficient atmosphere for industrial processes to thrive.

FAQS

: Industrial duct heaters are used to control temperature in various industrial applications, including preheating air for process equipment, maintaining comfort in large commercial spaces, and aiding drying processes in manufacturing.

The main types of duct heaters include electric heaters, gas heaters, and hot water heaters, each suited for different heating requirements based on the operational environment and energy sources.

Modernized duct heating systems can reduce energy consumption in industrial heating processes by up to 30% due to the incorporation of smart controls and predictive analytics for real-time monitoring and adjustments.

Innovations such as infrared heating elements and high-velocity air systems are enhancing thermal management in various applications, leading to improved efficiency and reduced carbon emissions.

Businesses can evaluate the ROI by analyzing cost-benefit metrics such as initial costs, energy savings, payback periods, and net present value (NPV) to assess the financial returns of their investment.

Duct heaters offer indirect benefits, such as improved product quality, reduced production waste, minimized downtime from temperature fluctuations, and enhanced employee comfort and productivity.

Facilities adopting advanced duct heating technologies can reduce carbon emissions by as much as 20%, aligning energy efficiency improvements with sustainable practices.

Factors to consider include the specific heating requirements, the operational environment, energy sources, and compliance with safety regulations.

Effective temperature control is crucial for operational efficiency, enhancing productivity, and ensuring a safer work environment, especially during colder seasons.

Conclusion

Industrial Duct Heaters are crucial components in optimizing temperature control across various industrial applications. By understanding the different types and their specific uses, industries can enhance performance significantly. Key factors influencing the efficiency of these heaters include their size, design, and best installation practices. Conducting an energy consumption analysis reveals how duct heaters compare favorably with other heating solutions, particularly when supported by innovative temperature control technologies driving efficiency.

To ensure the longevity and performance of Industrial Duct Heaters, adhering to maintenance best practices is essential. This not only preserves the equipment but also enhances the overall return on investment (ROI) for businesses. At Jiangsu Weineng Electric Co., Ltd., we leverage our extensive experience in designing, producing, and commissioning explosion-proof electric heaters to deliver high-quality duct heating systems tailored to meet industrial demands.

Related Posts

-

How to Choose the Right China Customized Industrial Heater Manufacturers for Your Business Needs

-

Understanding Industrial Duct Heaters: Essential Insights for Optimal Performance and Efficiency

-

Maximize Efficiency and Safety with Advanced Industrial Duct Heaters in Modern Manufacturing

-

Evaluating the Best Customized Industrial Heater Suppliers: A Comprehensive Comparison Guide

-

How to Choose the Right Industrial Heater Bundle for Your Business Needs

-

How to Maximize Efficiency with China Industrial Heating Bundle Solutions

Blog Tags: