Revolutionizing Heat Solutions with Industrial Immersive Heater Technology

Table of Contents

- Understanding Industrial Immersive Heater Technology

- Key Benefits of Immersive Heating Solutions

- Applications of Immersive Heater Technology in Various Industries

- Comparative Analysis: Immersive Heaters vs. Traditional Heating Methods

- Future Trends in Industrial Heating Technologies

- FAQS

- Conclusion

- Related Posts

Lately, there’s been a real surge in demand for more advanced heating tech across different industries. It’s all about improving efficiency and safety, you know? I read that, according to MarketsandMarkets, the global market for industrial heating is expected to hit over $300 billion by 2025. That’s pretty huge growth, especially in sectors that need specialized solutions.

At Jiangsu Weineng Electric Co., Ltd., we’re proud to be leading the charge, especially with our Industrial Immersive Heater tech. It’s pretty game-changing — not only does it deliver efficient heat transfer, but it also helps cut down energy use and lowers operational risks. With our deep experience in designing, building, and installing explosion-proof electric heaters, we’re really at the forefront of this shift. We’re committed to meeting the complex heating needs of modern industries while making sure everything stays safe and reliable.

Understanding Industrial Immersive Heater Technology

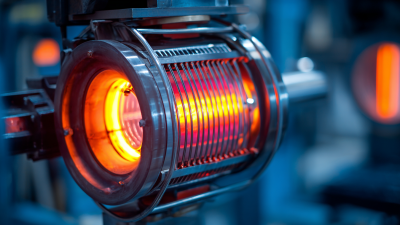

You know, Industrial Immersive Heater Technology is really starting to make waves as a game-changer when it comes to heat solutions—especially in industries that need high efficiency and want to keep things safe. What’s cool about this tech is that it spreads heat evenly and uses energy way more effectively, which can really boost how smooth industrial processes run. Thanks to innovative designs and smart engineering, these immersive heaters help cut down the risk of overheating, giving you a more controlled and safer heating environment.

At Jiangsu Weineng Electric Co., Ltd., we’ve got a solid background in making explosion-proof electric heaters, and we're excited to be adopting this new technology. Our focus on quality and safety means we deliver dependable heating solutions tailored to fit a wide range of client needs. Switching over to industrial immersive heaters isn’t just about keeping up with the times; it’s a move toward safer, more sustainable heating options that can actually boost productivity across different industries.

A quick tip—when you're thinking about upgrading to this kind of heater, take a close look at what your specific heating needs are. Getting the right size and setup can really improve performance and save energy. And don’t forget, regular upkeep and sticking to safety standards are super important to keep your heating systems running reliably for the long haul.

Revolutionizing Heat Solutions with Industrial Immersive Heater Technology

Key Benefits of Immersive Heating Solutions

Industrial Immersive Heater Technology is really changing the game when it comes to heating solutions across different industries. One of the coolest things about immersive heating is how efficient it is. Instead of just warming the air around your material, it heats the material directly — which means you end up using way less energy. Plus, this direct heat transfer makes things go faster, so production lines get moving quicker and you save some serious cash in the long run.

If you’re thinking about jumping into immersive heating, a good tip is to really get a handle on what your materials need in terms of heat. Knowing their thermal properties can help you pick the perfect system for your specific situation.

And here's another thing — precision. These systems heat things evenly, so you don’t get those annoying hot or cold spots that can ruin products. That kind of consistency is a big deal, especially if you’re in manufacturing or food processing where quality really counts.

One more tip — keeping your immersive heaters well-maintained is key. Regular cleaning and check-ups ensure they keep working smoothly, which not only helps them last longer but also keeps your product quality top-notch.

Revolutionizing Heat Solutions with Industrial Immersive Heater Technology - Key Benefits of Immersive Heating Solutions

| Feature | Description | Key Benefit | Application Areas |

|---|---|---|---|

| Energy Efficiency | Utilizes advanced technology to minimize energy consumption compared to traditional heating methods. | Reduces operational costs and carbon footprint. | Manufacturing, Warehousing |

| Rapid Heating | Provides quick heating capabilities, minimizing downtime in production processes. | Increases productivity and efficiency. | Food Processing, Chemical Production |

| Uniformity of Heating | Ensures even distribution of heat across surfaces and materials. | Enhances product quality and consistency. | Textile, Electronics |

| Modular Design | Offers flexibility in installation and scaling operations based on production needs. | Adapts to changing demand and reduces the need for extensive modifications. | Plastics, Aerospace |

| Safety Features | Includes built-in safety mechanisms for overheating and equipment malfunction. | Reduces risk of accidents and ensures compliance with safety regulations. | Manufacturing, Construction |

Applications of Immersive Heater Technology in Various Industries

Industrial Immersive Heater Technology is really set to shake things up across a bunch of different industries with its flexible uses. In manufacturing, for example, these high-tech heaters boost efficiency by spreading heat out evenly, which helps cut down on energy use and speeds up production. Industries like metalworking see a lot of benefits because having precise and controlled heating is so important—think forging and casting. Being able to heat materials quickly and uniformly not only speeds up the whole process but also boosts the quality of the final product.

When it comes to the food and beverage world, immersive heater tech really shines by keeping the temperature just right during cooking and processing. It makes sure the food heats evenly, so you don’t end up with hotspots that mess up the cooking process. Plus, these heaters are pretty energy-efficient, which is a big plus for companies trying to go greener and lower their carbon footprint. As industries look for smarter, more innovative ways to stay competitive, I wouldn't be surprised if using immersive heaters becomes the new norm—that could really push forward both productivity and sustainability efforts.

Comparative Analysis: Immersive Heaters vs. Traditional Heating Methods

Lately, there's been a real buzz around finding more efficient ways to heat things up in industrial settings. You know, we've traditionally relied on methods like convection or radiant heating — those have been the standard go-tos for ages. But now, immersive heater tech is starting to shake things up and is seen as a pretty exciting, if not revolutionary, alternative. I came across a recent report from Global Industry Analysts that predicts the market for these immersive solutions will grow at about 8.5% annually over the next five years. A big part of why they’re gaining popularity is because they’re more energy-efficient and help cut down on operational costs — who doesn’t love that?

Lately, there's been a real buzz around finding more efficient ways to heat things up in industrial settings. You know, we've traditionally relied on methods like convection or radiant heating — those have been the standard go-tos for ages. But now, immersive heater tech is starting to shake things up and is seen as a pretty exciting, if not revolutionary, alternative. I came across a recent report from Global Industry Analysts that predicts the market for these immersive solutions will grow at about 8.5% annually over the next five years. A big part of why they’re gaining popularity is because they’re more energy-efficient and help cut down on operational costs — who doesn’t love that?

So, how do immersive heaters work? Well, instead of just warming the air around a piece, they actually transfer heat directly to the material you're working with. That means less heat waste and a more even temperature across whatever you’re heating up. The International Journal of Thermal Sciences even reports that using immersive heating can cut energy use by up to 30% compared to traditional methods. That’s a pretty significant savings on your energy bill, which adds up pretty quickly for big operations.

Pro tip: If you're thinking about switching over to immersive heating, it’s a smart move to do a detailed cost-benefit analysis first. Look into your current energy and maintenance costs, as well as any potential downtime — these are key to making a solid decision.

And don’t forget, it’s a good idea to test out different models — sizes and wattages — to see which one fits your specific needs best. Touch base with manufacturers and maybe run some pilot programs. That way, you'll get a better idea of the actual performance gains before making a full-on investment.

Future Trends in Industrial Heating Technologies

The landscape of industrial heating technology around the world is changing pretty quickly these days. Companies are always coming up with new solutions to boost efficiency and move toward more sustainable practices. It’s kind of mind-blowing – experts say the market for heating equipment might hit a whopping $553 billion by 2024, and then jump even more to about $748 billion by 2032. This really shows how there's a growing buzz around advanced heating tech that not only handles industrial needs but also helps save energy.

More and more industries are jumping on the bandwagon with immersive heater tech, and it looks like there’ll be a big push toward integrating renewable energy sources too. The renewable energy sector itself is expected to grow to around $1,574 billion by 2032, which is pretty huge. All these developments mean industries have the chance to ditch old-school heating methods in favor of more eco-friendly options, which can cut down their carbon footprint while still keeping operations running smoothly.

My advice? Think about investing in smart heating systems that let you monitor and control things in real time. It’s a simple way to boost efficiency and cut energy bills at the same time. Jumping on these new tech trends isn’t just smart; it can really give your business a leg up in a competitive market and set the stage for more sustainable industrial practices.

FAQS

: Industrial Immersive Heater Technology is an advanced heating solution that enables uniform heat distribution and improved energy efficiency, minimizing the risk of overheating in industrial processes.

The primary benefits include enhanced energy efficiency, reduced energy consumption by directly heating materials, quicker production cycles, cost savings, and improved precision with uniform heating that minimizes hot or cold spots.

By providing uniform and efficient heating, immersive heater technology reduces production times and defects, leading to higher productivity in manufacturing and other industries.

Safety is critical as it minimizes the risks associated with overheating and potential hazards, ensuring reliable operation and protecting personnel and equipment.

Companies should evaluate the specific heating requirements of their operations, including the thermal properties of materials and proper sizing and configuration, to enhance performance and energy savings.

Regular maintenance, including keeping components clean and ensuring efficient functioning, is essential for optimal performance and longevity of heating systems.

Jiangsu Weineng Electric Co., Ltd. leverages its experience in manufacturing explosion-proof electric heaters to provide reliable, quality heating solutions that embrace industrial immersive heater technology.

Immersive heating technology is especially beneficial in manufacturing and food processing industries, where consistent quality and efficiency are critical to operations.

Conclusion

Hey, I came across this really interesting article called "Revolutionizing Heat Solutions with Industrial Immersive Heater Technology." It dives into some of the latest advances in heating stuff, especially focusing on this cool thing called Industrial Immersive Heater tech. The article explains the basics in a way that really highlights why immersive heating is such a game-changer — stuff like how it’s more efficient and uses less energy. It’s pretty impressive, especially when you see how these heaters are being used across different industries. Honestly, they seem way more effective and versatile compared to the old-school methods we’re used to.

Plus, they talk a lot about what’s coming next for industrial heating, like the trends that’ll keep pushing the sector forward. Jiangsu Weineng Electric Co., Ltd., is mentioned as a high-tech company that makes explosion-proof electric heaters. With their expertise in design and installation, they’re gearing up to make the most of these new techs and keep improving heating solutions for all kinds of industrial needs. Overall, it’s a pretty exciting look at where things are headed in this field.

Related Posts

-

Exploring Innovative Alternatives: The Future of the Best Electric Process Heater for Global Buyers

-

Evaluating the Best Customized Industrial Heater Suppliers: A Comprehensive Comparison Guide

-

Challenges Faced by Industrial Heating Bundle Factories in Modern Manufacturing

-

How to Choose the Right China Customized Industrial Heater Manufacturers for Your Business Needs

-

How to Identify the Best Industrial Immersive Heater Supplier for Your Needs

-

How to Choose the Right Industrial Heater Bundle for Your Business Needs

Blog Tags: