What is the Significance of Best Custom Immersion Heater in Industrial Applications

Table of Contents

- The Role of Custom Immersion Heaters in Boosting Industrial Efficiency

- Key Industry Applications for Best Custom Immersion Heaters

- Comparative Analysis: Standard vs. Custom Immersion Heaters

- Energy Efficiency Metrics for Immersion Heating Solutions

- Future Trends in Immersion Heater Technologies for Industry

- Maximizing Efficiency and Performance with Customized Industrial Immersion Heaters

- FAQS

- Related Posts

In the ever-changing world of industrial applications, you can’t really overlook the importance of custom immersion heaters. I mean, with the global industrial heating market expected to hit around $73.3 billion by 2027, it’s clear that folks are really looking for tailored heating solutions more than ever.

One company that's making waves in this space is Jiangsu Weineng Electric Co., Ltd. They’re pretty much at the forefront, specializing in explosion-proof electric heaters and have built a solid reputation when it comes to design, manufacturing, and getting these heaters up and running. As industries put more emphasis on safety and efficiency, custom immersion heaters are becoming absolute essentials—they help keep temperatures just right and perform reliably across all kinds of processes.

In this blog, I’ll be diving into why these specialized heaters matter so much, looking at where they’re used, their benefits, and how innovative companies like Weineng are stepping up to meet the rising demands of industry folks like you and me.

The Role of Custom Immersion Heaters in Boosting Industrial Efficiency

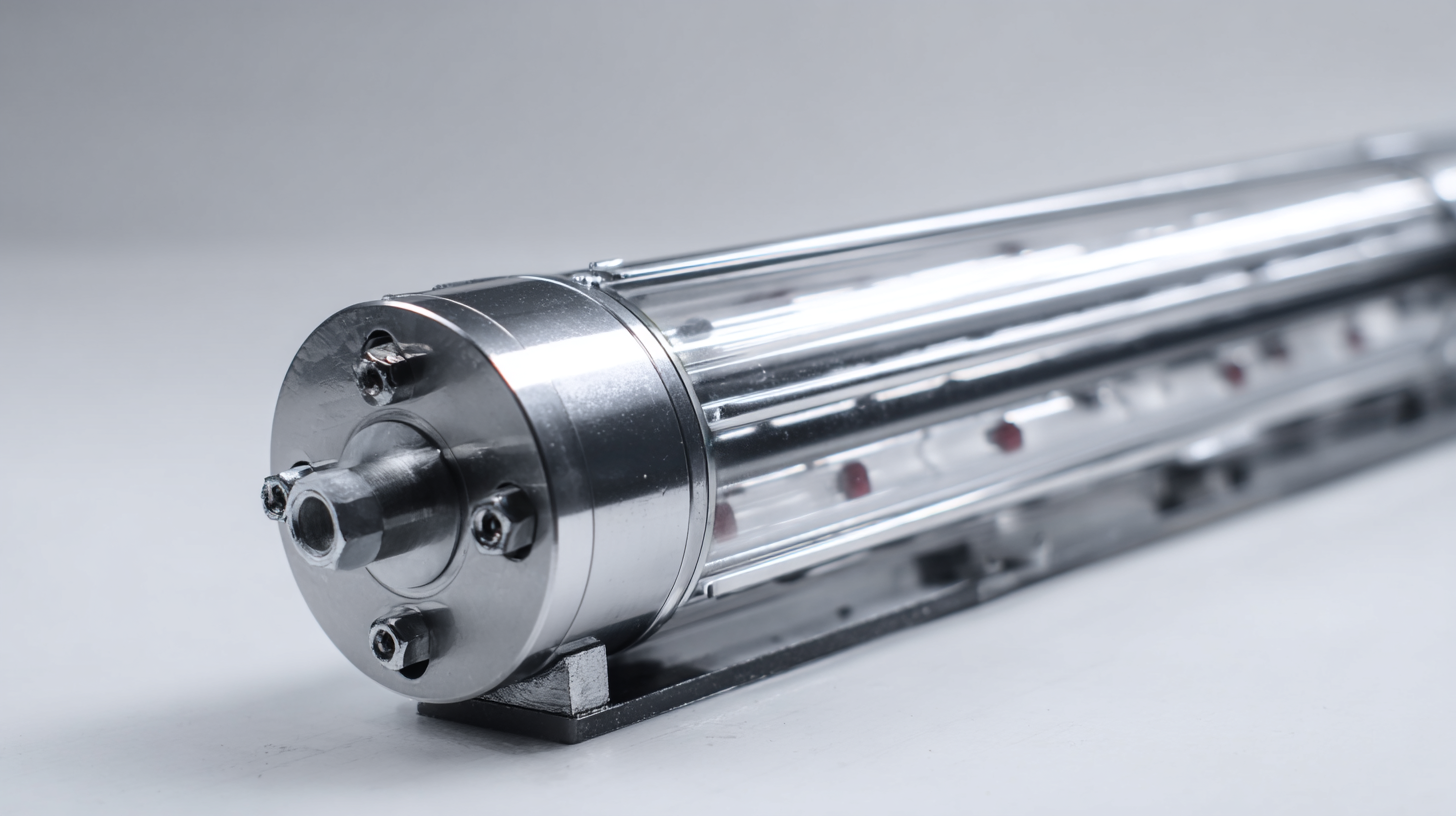

In today's fast-moving industrial world, custom immersion heaters are pretty much essential for boosting efficiency and keeping things running smoothly. These heaters are specially designed to fit specific operational needs, whether it's heating liquids, supporting chemical reactions, or just maintaining a steady temperature. Using the right immersion heater can really help industries cut down on energy bills and avoid costly downtime due to equipment breaking down.

When you're picking out a custom immersion heater, it’s important to look at what material the heating element is made of and how much watt density it has—these details directly impact how well it heats. Here's a little tip: if you're dealing with aggressive fluids, go for corrosion-resistant materials. It might cost a bit more upfront, but it pays off by preventing early failures and lasting longer. Also, making sure the heater is well-insulated can really help minimize heat loss, making everything more efficient and reliable.

On top of that, adding some smart controls and automation can really take things to the next level. Things like temperature sensors and programmable logic controllers (PLCs) help monitor and manage your heating process better. They can respond quickly to temperature changes, keeping everything running smoothly. Not only does this bump up efficiency, but it also helps in maintaining the quality of the final product. It’s all about making sure everything works just right, without too much hassle.

Significance of Best Custom Immersion Heater in Industrial Applications

| Application Area | Heating Capacity (kW) | Material Type | Temperature Range (°C) | Efficiency (%) |

|---|---|---|---|---|

| Chemical Processing | 50 | Stainless Steel | 20 to 150 | 90 |

| Food Processing | 30 | Titanium | 10 to 100 | 92 |

| Plastics & Polymers | 80 | Copper | 30 to 200 | 88 |

| Oil & Gas | 100 | Incoloy | 50 to 250 | 85 |

| Pharmaceuticals | 40 | Aluminum | 15 to 120 | 89 |

Key Industry Applications for Best Custom Immersion Heaters

When it comes to industrial settings, custom immersion heaters really play a crucial role across different sectors. Their flexibility means they can be tailored to meet unique temperature and heating needs, which is why you’ll find them essential in industries like food processing, oil and gas, and even renewable energy. Thanks to advances in technology, the global market for electric industrial heaters is expected to grow pretty significantly — experts estimate it could hit about USD 2.6 billion by 2034. It’s obvious that businesses are increasingly relying on precise, purpose-built heating solutions to keep everything running smoothly and efficiently.

One of the main uses for these custom heaters is in food processing, where keeping temperatures consistent is absolutely critical. They help make drying processes more efficient and help preserve the quality of the food products. On the other hand, in the oil and gas industry, these heaters are used to warm up thick, viscous fluids, making sure they flow properly and that the processing goes on without a hitch. Companies like Jiangsu Weineng Electric Co., Ltd. are really pushing the envelope — they specialize in designing explosion-proof electric heaters, which are super important for safety and reliability in dangerous environments. All in all, the versatility of custom immersion heaters makes them pretty much irreplaceable for meeting the diverse heating needs across different industries.

Comparative Analysis: Standard vs. Custom Immersion Heaters

When you really look into how important custom immersion heaters are in industrial settings, it’s clear that comparing standard and custom designs sheds a lot of light on their efficiency and performance. Standard heaters are pretty common and usually do the job just fine for a lot of applications. But, in some pretty demanding environments—like food processing or pharma where getting the temperature just right is super important—they often fall short. That’s where custom heaters come in clutch. They can be tailored to specific needs, offering different watt densities and thermal responses that make a real difference. For example, a report from the National Renewable Energy Laboratory mentioned that using custom heaters could boost energy efficiency by up to 30% in certain industrial setups.

On top of that, custom immersion heaters are way more versatile because they can be integrated with advanced monitoring systems—something standard models usually can’t handle. Think about biotech stuff—where real-time temperature control is a game-changer during processes like tissue diagnosis. A recent study pointed out that going with custom solutions not only gives you more flexibility but can also save a ton of money in the long run—thanks to lower energy bills and less maintenance. Basically, when industries fine-tune their heating setups to match their exact needs, they end up streamlining their workflow and boosting overall productivity. It’s all about making smarter choices that really fit what you’re trying to do.

This bar chart compares the efficiency ratings of standard immersion heaters versus custom immersion heaters in industrial applications. The data shows that custom immersion heaters provide a higher efficiency rating, making them a more suitable choice for specific industrial needs.

Energy Efficiency Metrics for Immersion Heating Solutions

When it comes to immersion heating solutions, especially in industrial settings, the importance of being energy-efficient really can't be stressed enough. You know, metrics like Power Usage Effectiveness (PUE) are pretty much the go-to for figuring out how well systems—like those in data centers or factories—are using energy. Basically, by checking out how much power is coming into a facility versus what the computing equipment uses, companies can spot chances to do better, save some cash, and cut down on waste. This is super important because the industrial water heater market is expected to grow a lot, thanks to rising energy needs and tighter rules around efficiency.

If you’re looking to boost energy efficiency in these systems, a good starting point is to keep an eye on your PUE metrics regularly. Comparing your numbers to industry standards helps you see where you stand and what you might need to fine-tune. Going a step further, using new tech like hybrid load banks or switching to liquid cooling methods can really help manage heat better while using less energy. And don’t forget about life cycle assessment tools—they can point out greener options that push innovation and keep industrial heating more sustainable. Adopting these strategies doesn’t just help you stay compliant with regulations; it also honestly puts your company ahead in the sustainability game—and that often translates to more efficient operations and a better reputation.

All in all, making these tweaks can really make a difference and help balance performance with environmental responsibility without too much hassle.

Future Trends in Immersion Heater Technologies for Industry

Looking ahead, the future of immersion heaters for industrial use is shaping up to be pretty exciting. Thanks to the booming global market for heating equipment, we're expecting some big changes. The numbers tell it all—demand's projected to jump from around $115.6 billion in 2025 to about $171.8 billion by 2032. As that growth continues, companies are gonna start really focusing on making stuff that's not only efficient but also environmentally friendly. You know, the whole smart tech integration thing is going to make these heaters smarter, more energy-efficient, and a lot greener, which is great news for those trying to cut down on energy waste.

One of the coolest trends right now is folks looking into hydrogen energy systems. As industries try to get serious about tackling climate change, hydrogen could totally change the game, offering a cleaner alternative to traditional heating methods. With new materials, better efficiency, and smaller, sleeker designs, immersion heaters are probably going to evolve in a big way—giving industries powerful tools that are also eco-friendly.

If your company’s thinking about jumping into these new tech waters, a couple of tips: first, make sure the new heaters will work smoothly with what you've already got in place. Also, don’t forget to look at the overall costs over time—not just the sticker price. Lastly, investing in good training and proper maintenance now can really pay off later. Staying in the loop about new tech trends and getting ready for what’s coming will help your business run smoother, be more efficient, and stay on top of those increasing regulations.

Maximizing Efficiency and Performance with Customized Industrial Immersion Heaters

In today's competitive industrial landscape, maximizing efficiency and performance is paramount. Customized industrial immersion heaters from WNH offer a tailored solution designed to optimize your specific processes and applications. Research indicates that properly engineered immersion heaters can enhance overall energy efficiency by as much as 30% compared to generic models. Our dedicated team collaborates closely with clients to understand their unique requirements, ensuring that every heater is meticulously designed around individual operational needs, budget constraints, and environmental factors.

Choosing the right materials and configurations is critical in achieving the desired performance outcomes. For instance, selecting the appropriate wattage and heater type can drastically influence both the heating time and the longevity of the equipment. Industry studies have shown that utilizing custom immersion heaters can lead to an increase in lifespan by over 50%, significantly reducing replacement costs and downtime. By relying on our expertise, clients can confidently navigate these choices, leading to a more effective heating solution that aligns with their operational goals.

In addition, WNH emphasizes the importance of continuous support and adaptation of heater designs to accommodate changing industrial requirements. As organizations face evolving challenges and technological advances, having a customized immersion heater is essential in maintaining consistent performance levels. With WNH's tailored approach, industries can achieve not only immediate efficiency improvements but also long-term sustainability in their heating processes.

FAQS

: Custom immersion heaters are essential in various industries, including food processing, oil and gas, and renewable energy, due to their ability to meet specific temperature and heating requirements.

In food processing, custom immersion heaters ensure consistent temperature control, facilitating efficient drying processes and maintaining the quality of food products.

These heaters are used to heat viscous materials in the oil and gas sector, ensuring smooth flow and efficient processing.

Energy efficiency is crucial in industrial applications to manage high-density demanding workloads, reduce operational costs, and comply with stringent regulations on energy use.

Metrics like Power Usage Effectiveness (PUE) are critical for assessing the energy efficiency of systems in industrial settings and identifying opportunities for optimization.

Strategies include monitoring PUE metrics, implementing advanced technologies like hybrid load banks, adopting liquid cooling methods, and using life cycle assessment tools.

The global electric industrial heater market is projected to grow significantly, reaching USD 2.6 billion by 2034, driven by the increasing reliance on precision heating solutions.

Companies like Jiangsu Weineng Electric Co., Ltd. specialize in manufacturing explosion-proof electric heaters, emphasizing safety and performance in hazardous environments.

Embracing sustainable practices can improve operational efficiency, help with regulatory compliance, and position organizations as leaders in sustainability.

Advancements in technology enhance the performance and adaptability of custom immersion heaters, ensuring they meet diverse heating requirements across various industries.

Related Posts

-

Exploring Innovative Alternatives: The Future of the Best Electric Process Heater for Global Buyers

-

Premium Electric Heater Solutions from China Your Trusted Global Manufacturing Partner

-

Innovative Solutions for Industrial Heating Challenges in Manufacturing Environments

-

Ultimate Guide to Choosing the Best China Flange Immersion Heater for Your Needs

-

Emerging Technologies for Industrial Flange Heater Solutions by 2025

-

Exploring Unique Features of Industrial Heating Bundles and How to Select the Best Supplier

Blog Tags: