Top 10 Tips for Choosing the Best Industrial Heater Bundle in China

Table of Contents

- Understanding Industrial Heater Bundles and Their Importance

- Key Factors to Consider When Choosing an Industrial Heater

- Evaluating Heater Types: Electric vs. Gas vs. Infrared

- Assessing Heating Capacity and Efficiency Requirements

- Reviewing Safety Standards and Compliance in China

- Analyzing Cost vs. Value: Budgeting for Your Heater Bundle

- Looking into Manufacturer Reputation and After-Sales Support

- Enhancing Energy Efficiency: The Impact of 440V 90KW Industrial Heater Bundles on Operational Costs and Sustainability in Manufacturing

- FAQS

- Conclusion

- Related Posts

When you're looking to find the perfect heating solutions for industrial setups, the China Industrial Heater Bundle really stands out as a go-to choice for many businesses wanting to boost their efficiency. With China’s manufacturing scene exploding and so many different heating options out there, it can get pretty overwhelming trying to pick the right one. That’s exactly why I put together this quick guide with the top ten tips—so you can confidently choose an industrial heater bundle in China that fits your needs and budget without all the stress.

Understanding what makes these industrial heaters tick is pretty important whether you’re in procurement or managing a facility. The right bundle isn’t just about heating; it should also help save energy and keep maintenance costs in check. Each tip I’ve shared will help you evaluate stuff like how well it heats, whether it plays nice with your existing setup, and how reliable it is overall. Whether you’re running a tiny workshop or a huge manufacturing plant, making a smart choice can really make a difference in your efficiency and sustainability down the line. Arm yourself with some good info, and you’ll be navigating China’s competitive industrial heating market like a pro.

Understanding Industrial Heater Bundles and Their Importance

Industrial heater bundles are essential for various manufacturing and processing applications in China, where maintaining optimal temperature conditions is crucial for efficiency and product quality. These bundles typically consist of multiple components designed to work together seamlessly, including heating elements, controls, and safety devices. Understanding their importance is key to selecting the best option for your specific needs.

First, industrial heater bundles provide a comprehensive solution that can significantly reduce installation time and complexity. By incorporating all necessary components into a single package, they minimize compatibility issues and installation delays. Furthermore, these bundles are often designed with energy efficiency in mind, helping businesses reduce operational costs while maintaining high performance. Adopting the right heater bundle can enhance productivity, minimize downtime, and ensure safe operation within various environments, underscoring their significance in industrial applications.

Key Factors to Consider When Choosing an Industrial Heater

When choosing an industrial heater in China, several key factors should be meticulously considered to ensure optimal performance and suitability for your specific application. First and foremost, the heater's type and design play a crucial role. Options may include electric, gas, or oil heaters, each having distinct advantages and disadvantages depending on the environment and requirements. Understanding the heat output and efficiency ratings is essential; these specifications determine the heater's effectiveness in maintaining temperature stability across various industrial processes.

Another critical aspect is the heater's operating environment. Factors such as ambient temperature, humidity levels, and space constraints must be evaluated, as they can significantly impact the heater’s performance and longevity. Additionally, the material quality and construction of the heater directly relate to its durability and resistance to wear, especially in demanding conditions. It is also advisable to assess the availability of spare parts and technical support, which can greatly affect maintenance and operational continuity. Whether integrating new heaters into existing systems or starting from scratch, carefully analyzing these factors will lead to a well-informed decision that meets operational needs.

Evaluating Heater Types: Electric vs. Gas vs. Infrared

When selecting an industrial heater bundle, one of the most critical decisions is choosing the appropriate type of heater, with electric, gas, and infrared options being the most common.

Electric heaters are often favored for their ease of installation and operation. They require minimal maintenance and offer precise temperature control. Additionally, electric heaters are considered environmentally friendly since they do not produce emissions during operation. However, they may have higher operational costs depending on local electricity rates.

Gas heaters, on the other hand, typically provide higher heating output and can be more cost-effective in areas where natural gas is readily available. They are ideal for large spaces where rapid heating is necessary. However, gas heaters require proper ventilation to prevent the accumulation of harmful gases, and their installation may involve more complexity compared to electric options.

Infrared heaters are gaining popularity for their ability to heat objects and people directly rather than warming the air around them. This makes them especially effective in large warehouses or open areas where immediate warmth is desired without the need to heat the entire space. Each type of heater has its advantages and disadvantages, making it crucial for businesses to evaluate their specific heating needs and conditions before making a decision.

Assessing Heating Capacity and Efficiency Requirements

When choosing an industrial heater bundle in China, understanding heating capacity and efficiency requirements is crucial. The heating capacity should match the specific needs of your workspace, taking into account factors such as the size of the area, insulation quality, and the nature of the processes involved. Ensure that the heater can maintain optimal temperatures across varying load demands. It’s advisable to calculate the required BTUs or watts based on these factors to avoid under- or over-sizing, which can lead to inefficiencies and increased operational costs.

Efficiency is another vital aspect that directly impacts energy consumption and costs. Look for heaters with high annual fuel utilization efficiency (AFUE) ratings. A more efficient heater not only saves money but also contributes to reducing environmental impact by lowering emissions. Additionally, consider features such as adjustable thermostats and multi-stage heating settings, which can enhance energy efficiency by allowing the heater to adapt to real-time requirements rather than operating at full capacity continuously.

Lastly, don’t overlook the importance of flexibility in design and installation. Selecting a heater that can be easily integrated into your existing systems or that can be modified in response to changing demands can offer long-term benefits. Regulating the temperature efficiently with the right heater bundle will ultimately support productivity and comfort within your industrial space.

Reviewing Safety Standards and Compliance in China

When selecting an industrial heater bundle in China, understanding safety standards and compliance is crucial for ensuring both worker safety and equipment efficiency.

The Chinese government has established rigorous standards that govern the production, operation, and maintenance of industrial heating equipment.

Compliance with these standards not only minimizes the risk of workplace accidents but also ensures that the heater operates safely and efficiently, reducing the potential for equipment failure and associated costs.

Additionally, it is essential for manufacturers to adhere to internationally recognized safety protocols, such as those outlined by organizations like ISO or IEC.

This can add an extra layer of assurance regarding product quality and operational safety.

Buyers should take the initiative to verify the certifications and compliance documentation of the industrial heater bundles they are considering, ensuring that all safety regulations related to

electrical safety, thermal performance, and

material durability are met.

By prioritizing safety and compliance, businesses can protect their workforce while enhancing the longevity and reliability of their heating solutions.

Analyzing Cost vs. Value: Budgeting for Your Heater Bundle

When analyzing cost versus value in selecting an industrial heater bundle, it's essential to approach budgeting with a clear understanding of your specific needs and potential return on investment. According to a recent market analysis by the International Energy Agency, industrial heating costs account for up to 30% of total energy expenditures in manufacturing sectors. This statistic highlights the importance of investing in a heater bundle that not only fits within your budget but also maximizes energy efficiency to reduce long-term operational costs.

Choosing the right industrial heater is not merely about the upfront price; it involves evaluating the overall value it brings to your operations. A report by the Energy Research Institute suggests that high-efficiency heater bundles can lower energy consumption by approximately 20-30%, translating to significant savings over time. Moreover, investing in advanced control systems can further enhance operational efficiency, minimizing maintenance costs and decreasing downtime. Balancing initial costs with potential energy savings, therefore, should be central to your budgeting strategy, ensuring that the heater bundle you choose delivers optimal performance while remaining financially viable in the long run.

Looking into Manufacturer Reputation and After-Sales Support

When choosing the best industrial heater bundles in China, assessing the manufacturer's reputation is crucial. A strong reputation often reflects a company’s commitment to quality and reliability. Look for manufacturers with a proven track record in the industry. This can be gauged through customer reviews, case studies, and testimonials. Engaging with previous clients and understanding their experiences can provide insights into the manufacturer's reliability and performance standards. A reputable manufacturer is more likely to invest in research and development, ensuring that their products meet the latest industry standards.

In addition to reputation, after-sales support is a vital consideration. A manufacturer should offer robust support services, including installation guidance, maintenance, and troubleshooting assistance. A long-term partnership with suppliers who prioritize after-sales service can prevent production downtimes and enable efficient operation. Evaluate the support options available, such as warranty terms, response times for service requests, and accessibility of spare parts. A reliable after-sales support system not only enhances the longevity of the industrial heaters but also fosters a trusting relationship between the manufacturer and the buyer, ultimately leading to a more satisfying purchasing experience.

Enhancing Energy Efficiency: The Impact of 440V 90KW Industrial Heater Bundles on Operational Costs and Sustainability in Manufacturing

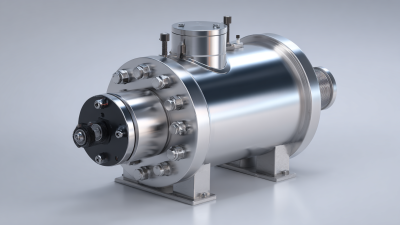

The manufacturing sector continually seeks ways to enhance energy efficiency while managing operational costs. One effective solution is the use of 440V 90KW industrial heater bundles. These advanced heating systems provide significant advantages in terms of energy savings and sustainability. By optimizing heat transfer, these heaters ensure that energy is utilized effectively, minimizing waste and reducing overall operational costs.

Flanged immersion elements play a crucial role in the effectiveness of these heater bundles. Designed for heating oils, liquids, and gases in large quantities, these process heaters can be tailored to meet a wide range of applications. Their flexibility in size and output allows manufacturers to select the ideal unit for their specific needs, ensuring optimal performance and efficiency. By implementing these heating solutions, facilities can not only lower their energy consumption but also contribute to a more sustainable production process.

Incorporating 440V 90KW industrial heater bundles into manufacturing operations aligns with the industry's increasing commitment to reducing environmental impact. By leveraging efficient heating methods, manufacturers can enhance their productivity while fostering a sustainable approach to energy use. The integration of advanced heating technology is vital for those striving to maintain competitiveness and sustainability in an ever-evolving market landscape.

FAQS

: Industrial heater bundles are comprehensive solutions that consist of multiple components, including heating elements, controls, and safety devices, designed to work together for various manufacturing and processing applications.

They are important because they reduce installation time and complexity, minimize compatibility issues, and are often designed for energy efficiency, which helps lower operational costs while maintaining high performance.

Key factors include the type and design of the heater, heat output and efficiency ratings, the operating environment (such as ambient temperature and humidity levels), material quality, construction durability, and the availability of spare parts and technical support.

Common types of heaters for industrial use include electric, gas, and oil heaters, each offering distinct advantages and disadvantages depending on specific environment and application requirements.

The operating environment, including factors like ambient temperature, humidity, and space constraints, can significantly impact a heater's performance and longevity.

High material quality and durable construction are crucial for a heater's resistance to wear and its overall durability, especially in demanding industrial conditions.

Adopting the right heater bundle can enhance productivity by minimizing downtime, ensuring safe operation, and maintaining temperature stability across various industrial processes.

Heat output and efficiency ratings are essential as they determine a heater's effectiveness in maintaining the required temperature stability for different industrial applications.

Conclusion

When selecting a China Industrial Heater Bundle, it is crucial to understand the significance of these products in various industrial applications. Key factors to consider include the type of heater—whether electric, gas, or infrared—which directly impacts efficiency and heating capacity. Assessing safety standards and compliance within China is essential to ensure reliability and avoidance of hazards.

Additionally, it’s important to analyze the cost versus value of the heater bundle, keeping your budget in mind while not compromising on quality or performance. Manufacturer reputation and after-sales support should also be evaluated to ensure you are making a well-informed decision that meets your industrial heating needs effectively.

Related Posts

-

How to Optimize Your Industrial Heater Bundle Pricing for Maximum Efficiency and Cost Savings

-

How to Choose the Best Customized Industrial Heater for Your Needs

-

The Ultimate Guide to Choosing the Best Industrial Flange Heater Suppliers for Your Needs

-

Top Industrial Heating Bundle Solutions for Efficient Manufacturing Processes

-

How to Choose the Right Industrial Heater Bundle Suppliers for Your Business Needs

-

How to Choose the Right Industrial Heater Bundle for Your Business Needs

Blog Tags: