The Ultimate Guide to Flange Industrial Heaters: Maximizing Efficiency and Safety in Your Operations

Table of Contents

- Understanding Flange Industrial Heaters: Principles and Applications

- Key Benefits of Flange Heaters in Industrial Processes

- Industry-Specific Data: Efficiency Metrics for Flange Heaters

- Safety Standards and Compliance in Flange Heating Operations

- Maintenance Best Practices for Maximizing Heater Lifespan

- Comparative Analysis: Flange Heaters vs. Other Heating Solutions

- Understanding the Benefits and Applications of Industrial Flange Heaters in Various Industries

- FAQS

- Conclusion

- Related Posts

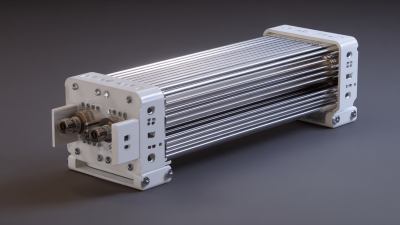

In today’s fast-moving industrial world, you really can’t overlook how important Flange Industrial Heaters are. These stuff aren’t just small parts—they’re crucial for a bunch of different applications, making sure heat is transferred efficiently while still keeping safety front and center. I’ve seen reports that suggest the global market for industrial heaters could hit around USD 3.5 billion by 2025 — and the demand is only growing, especially for explosion-proof options in risky environments. Companies like Jiangsu Weineng Electric Co., Ltd., are really leading the way. They’re a top-tier high-tech firm specializing in explosion-proof electric heaters, and they bring tons of experience to the table when it comes to designing, manufacturing, and setting up these systems. This guide’s all about helping you understand common issues with Flange Industrial Heaters and offering some practical tips on how to improve their performance in your own operations, with safety and efficiency in mind.

Understanding Flange Industrial Heaters: Principles and Applications

You know, flange industrial heaters are pretty much essential in a bunch of industries—think oil and gas, chemical processing, and even HVAC systems. They work by directly heating the equipment, which helps keep the temperature just right. What's pretty cool is that these heaters are based on electromagnetic principles—they generate heat through electromagnetic coupling, which means they’re pretty efficient and waste less energy. Getting a good handle on how they work can really help you make the most out of them in your operations.

When you're picking out flange industrial heaters, a few things to keep in mind: consider where you're going to use them and what your specific needs are. Make sure they’re rated to handle the pressure and temperature of your environment, especially if you’re dealing with explosive or corrosive conditions. You might also want to look into pipeline-style electromagnetic heaters that run on power frequency—they use transformer principles to give you steady, controlled heat, which is great for more complex setups.

A quick tip—safety first! When working in high-risk environments, opt for explosion-proof heaters to keep everyone safe. Regular maintenance is also super important—checking for any signs of wear and making sure the insulation’s in good shape can save you from potential problems down the line. And finally, tailoring the heater design to fit your specific application can really boost performance and help the equipment last longer.

Key Benefits of Flange Heaters in Industrial Processes

Flange heaters are pretty much essential when it comes to making industrial processes more efficient. They do a great job of delivering heat exactly where it’s needed—no wasting energy on areas that don’t need it. I recently read a report from the Thermal Equipment Manufacturers Association (TEMA), and it mentioned that using flange heaters can cut down energy use by up to 30% compared to old-school heating methods. That’s mainly because they focus the heat right on the surface of the fluid or material, which helps reduce heat loss and boosts overall efficiency.

But it’s not just about saving energy—flange heaters also make operations safer. A study by the Industrial Heating Association (IHA) found that systems equipped with flange heaters saw about a 25% drop in equipment failures caused by overheating. That’s largely thanks to their ability to keep temperatures steady and the fact that they can be hooked up to smart control systems that monitor conditions all the time. Better reliability means fewer expensive repairs and also less chance of accidents from thermal overload. All in all, flange heaters really are a game-changer in modern industry settings.

The Ultimate Guide to Flange Industrial Heaters: Maximizing Efficiency and Safety in Your Operations - Key Benefits of Flange Heaters in Industrial Processes

| Dimension | Description | Benefit |

|---|---|---|

| Heat Transfer Efficiency | Effective transfer of heat to fluids and solids. | Reduces energy consumption and increases output. |

| Installation Flexibility | Can be mounted in various orientations and locations. | Adaptable to custom configurations for different operations. |

| Safety Features | Includes thermal protection and overheat sensors. | Enhances operational safety and minimizes risks. |

| Durability | Constructed with robust materials resistant to corrosion. | Longer lifespan leading to lower replacement costs. |

| Energy Savings | Optimized designs for maximum energy utilization. | Lower overall energy bills for companies. |

| Maintenance | User-friendly maintenance protocols and accessibility. | Reduced downtime and operational disruptions. |

Industry-Specific Data: Efficiency Metrics for Flange Heaters

Flange industrial heaters really play a vital role across so many industries—think oil and gas, renewable energy, you name it. When it comes to figuring out how well these heaters perform, there are a few key metrics you want to keep an eye on. For example, looking at how effectively they transfer heat and how much energy they use can give you a pretty good idea of whether they’re doing their job in your specific setup. Keep tabs on these scores, and you can tweak things to make your heating systems run smoother. Not only does this help cut down on those pesky operational costs, but it also keeps safety levels high, which is super important.

If you're serious about getting the most out of your flange heaters, some simple tips can go a long way. Regular maintenance checks are a must—catch problems early before they turn into bigger issues. Also, wrapping those heating elements with insulation is a clever move to prevent heat from slipping away. And don’t forget about smart controls—they let you monitor what’s happening in real time and make quick adjustments when needed, boosting both efficiency and safety.

Choosing the right flange heater isn’t just about picking any model—it’s about matching it to your specific needs. Things like the environment you’re working in, what you’re actually heating, and the temperature ranges you need should all influence your choice. When you align your heater selection with your actual operational demands, you set yourself up for better performance and a safer, more efficient process.

The Ultimate Guide to Flange Industrial Heaters: Maximizing Efficiency and Safety

This bar chart illustrates the efficiency metrics of various flange heater models used in industrial applications. As shown, Model A leads with a 92% efficiency, demonstrating the importance of selecting the right equipment for operational effectiveness.

Safety Standards and Compliance in Flange Heating Operations

When it comes to flange industrial heaters, safety should always come first. Making sure your heating equipment complies with industry standards isn’t just about ticking boxes — it’s about protecting your team and keeping things running smoothly. Regular check-ups and maintenance are a must; they help catch problems before they turn into bigger, more dangerous issues. Adding safety features like overheat protection or automatic shut-off can really make a difference and reduce the risks involved with flange heating processes.

**A quick tip**: it’s super important to have a qualified professional install your system and be familiar with the safety standards involved. Also, running regular safety training for your staff helps build a culture where everyone’s aware of how to operate everything safely.

Plus, choosing the right materials is a big part of staying compliant. Go for heaters designed specifically for your applications and materials — that way, you boost both safety and performance. Knowing the thermal limits of your materials is key, too; overheating or damaging them can lead to costly failures down the line.

**Another tip**: keep an up-to-date safety standards checklist, and don’t forget to perform regular audits. Being proactive and catching issues early can save you a lot of headache later on.

Maintenance Best Practices for Maximizing Heater Lifespan

Taking good care of your flange industrial heaters really matters if you wanna keep them running smoothly and last a long time. It’s a smart move to do regular check-ups—look out for any signs of wear, like rust or electrical glitches.

And don’t forget to keep them free of dust and grime. Not only does that help them work better, but it also cuts down the chances of overheating. Setting up a cleaning routine and periodically checking those electrical connections and insulation can make a big difference—you might be surprised how much longer your heater lasts that way.

Another key thing is keeping an eye on the temperature. Running the heater at the right temp helps prevent unnecessary wear and tear, and stops it from overheating, which can cause it to break down early. Installing a monitoring system for temperature and overall performance can alert you to issues before they turn into big problems. Also, following the manufacturer’s tips for usage and maintenance is a smart idea—these guidelines often include simple tricks specific to your heater model that can save you a lot of hassle. Bottom line? By staying on top of these maintenance habits, you’ll keep your flange industrial heaters safe, efficient, and in great shape for years to come.

Comparative Analysis: Flange Heaters vs. Other Heating Solutions

When you're looking into industrial heating options, flange heaters really stand out—they're known for being both efficient and versatile. Unlike the more common cartridge or band heaters, flange heaters are built specifically to be mounted on flat surfaces. That makes them perfect for heating up fluids in tanks or big vessels. Because they make direct contact, they transfer heat more effectively and waste less energy, which means your process runs smoother and costs less in the long run.

If you compare flange heaters to other choices, you'll notice they have a few clear advantages. For one, they heat evenly across the whole surface, so you don’t have to worry about hot spots that could damage equipment or mess up your product quality. Plus, they’re usually easier to install and keep up with—so less downtime and fewer headaches for your team. And on the safety side of things? They help control temperatures better and offer good insulation, lowering the risks that come with overheating. All these factors make flange heaters not just a smart, efficient pick, but also a safer one—especially when dealing with the demanding nature of industrial work.

Understanding the Benefits and Applications of Industrial Flange Heaters in Various Industries

Industrial flange heaters have become essential in various sectors due to their efficiency and adaptability. These heaters excel in providing consistent and reliable heat in applications ranging from chemical processing to food production. Designed to optimize performance, flange heaters are located at the point of heat delivery, ensuring rapid and uniform temperature distribution. This makes them ideal for maintaining the desired viscosity of materials or enhancing the efficiency of processes that require precise thermal management.

WNH specializes in custom-manufactured immersion heaters tailored to meet the specific requirements of your industrial processes. Our team collaborates closely with clients to develop heaters that fit within budget constraints while addressing unique operational needs. By selecting appropriate materials, wattages, and configurations, we enhance the longevity and effectiveness of our products. This ensures that industries can achieve maximum efficiency, whether it is heating liquids in tanks or maintaining temperatures in pipelines. With a keen focus on application suitability, WNH helps businesses save energy and improve productivity through innovative heating solutions.

FAQS

: Flange industrial heaters are essential in applications such as oil and gas, chemical processing, and HVAC systems, providing efficient temperature control by applying heat directly to the equipment.

These heaters operate based on electromagnetic principles, generating heat through electromagnetic coupling, which enhances efficiency and minimizes energy waste.

When selecting heaters, consider the application environment, operational pressures, temperatures, and specific requirements, especially in explosive or corrosive settings.

Safety standards are crucial as they protect employees and enhance operational efficiency; ensuring compliance helps avoid malfunctions and potential hazards.

Incorporating safety features like overheat protection and automatic shut-off functions can significantly reduce risks associated with flange heating operations.

Regular maintenance helps prevent wear, inefficiencies, and hazards, ensuring the heating system operates safely and effectively.

Aligning heater design with specific application needs and choosing the right materials can significantly enhance operational performance and longevity.

Regular training sessions on safe operating procedures are essential to instill a culture of safety in the workplace.

Keep an updated checklist of applicable safety standards and conduct regular audits to identify potential safety issues before they escalate.

Understanding the thermal characteristics and limitations of the materials used in operations is essential for avoiding overheating or material degradation, which can lead to failures.

Conclusion

You know, Flange Industrial Heaters are pretty much essential when it comes to boosting both efficiency and safety in all sorts of industrial processes. They work on basic principles that make heat transfer really effective, which is why they're a go-to for applications that need precise temperature control. In this blog, we dive into some pretty important stuff — like the main benefits of these heaters, such as how they can improve thermal performance, plus some industry-specific data that shows just how well they perform.

But hey, it's not just about choosing the right heater. Following safety standards and keeping up with good maintenance habits are crucial to making sure these heaters last long and keep everyone safe. And speaking of experts, Jiangsu Weineng Electric Co., Ltd. has got you covered—specializing in building explosion-proof electric heaters. They provide custom solutions that help your operation run smoothly while ticking all the safety boxes. We also take a quick look at how flange heaters stand up against other heating options out there, and honestly, they just seem to have a lot of advantages in the industrial world.

Related Posts

-

Emerging Technologies for Industrial Flange Heater Solutions by 2025

-

Ultimate Guide to Choosing the Best China Flange Immersion Heater for Your Needs

-

Exploring Innovative Alternatives: The Future of the Best Electric Process Heater for Global Buyers

-

The Future of Finned Tube Heaters: Innovations Shaping Thermal Technology

-

What is the Significance of Best Custom Immersion Heater in Industrial Applications

-

Essential Checklist for Obtaining the Best Industrial Heater Bundle Quotes

Blog Tags: