The Ultimate Guide to Scr Control for Electric Heaters: Boosting Efficiency with Industry Insights

Table of Contents

- Understanding SCR Technology in Electric Heating Systems

- Key Benefits of Scr Control for Improved Heating Efficiency

- Common SCR Control Configurations in Electric Heaters

- Industry Case Studies: Successful SCR Implementations

- Future Trends in SCR Technology for Enhanced Energy Performance

- Enhance Efficiency and Safety: The Role of Electric Air Heaters in Dust Removal for Power Stations

- FAQS

- Conclusion

- Related Posts

When it comes to electric heating tech, everyone — whether you're a manufacturer or just someone interested — wants to squeeze out as much efficiency as possible. Over here at Jiangsu Weineng Electric Co., Ltd., we’re a high-tech startup that specializes in making explosion-proof electric heaters. We totally get how crucial it is to use advanced control methods to boost performance.

One really cool technique we're into is SCR control for electric heaters. It’s a game-changer because it not only helps save energy but also keeps the heat steady and reliable. In this guide, we’ll walk you through how SCR control works, what benefits it offers, and share some industry insights to help you make the most of it.

With our hands-on experience in design, production, and system setup, our goal is to give you the know-how to improve the efficiency of your electric heating systems — so, let’s dive in!

Understanding SCR Technology in Electric Heating Systems

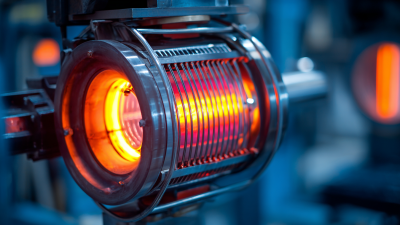

You know, Silicon Controlled Rectifier (SCR) tech has really reinvented the game when it comes to electric heating systems. These devices are pretty amazing because they give you much finer control over the electrical current, which means heating becomes more efficient and easier to manage. Interestingly, recent industry reports suggest that using SCRs can bump up energy efficiency by as much as 30%. That’s a big deal because it helps cut down on energy waste and lowers operational costs—pretty solid, right?

Plus, adding SCRs to electric heaters makes it a lot easier to keep the temperature just right, which is super important in settings where precision is a must. The International Energy Agency even pointed out that systems with smart SCR control can cut down temperature swings by about 20%, leading to more consistent product quality. And with everyone pushing for greener energy solutions these days, adopting SCR technology isn’t just a trend anymore—it’s almost becoming a must for businesses that want to lower their carbon footprint while staying productive. It’s like, staying ahead of the curve, you know?

The Ultimate Guide to Scr Control for Electric Heaters

| Parameter | Description | Typical Value | Impact on Efficiency |

|---|---|---|---|

| SCR Voltage Rating | Maximum voltage SCR can handle | 600V | Higher voltage rating improves reliability |

| Triggering Current | Current needed to turn on the SCR | 10mA | Lower triggering current enhances efficiency |

| Thermal Resistance | Resistance to heat flow from SCR to heat sink | 0.5°C/W | Lower thermal resistance improves heat dissipation |

| Switching Frequency | Frequency of on/off switching | 60Hz | Higher frequency typically boosts efficiency |

| Control Method | Method of SCR operation control | Phase Control | Improves temperature regulation and efficiency |

Key Benefits of Scr Control for Improved Heating Efficiency

You know, SCR (Silicon Controlled Rectifier) control tech has really changed the game when it comes to electric heaters. It's pretty cool because it offers a bunch of perks that help save energy and improve how well the heaters perform. One of the biggest wins with SCR control is how accurately it keeps the temperature just right. Instead of running at full blast all the time, it adjusts the power based on what’s needed. So, the heater stays at your preferred temp with hardly any fluctuations, which helps cut down on energy waste — basically, it only uses what’s necessary. Not to mention, it can help slash energy bills quite a bit.

Plus, these systems don’t just keep the temperature steady—they also make your equipment last longer. Traditional heaters tend to go through a lot because of guys subjecting their parts to huge temperature swings, which leads to faster wear and tear. SCR tech, on the other hand, runs smoothly and gently, reducing that thermal stress. That means your heating units stick around longer, and you won’t have to worry about constant repairs or maintenance costs. And, with everyone pushing for greener and more energy-efficient solutions, using SCR control can help businesses not only meet regulations but also go easy on the environment. All in all, it’s a pretty smart move toward more effective and responsible heating management.

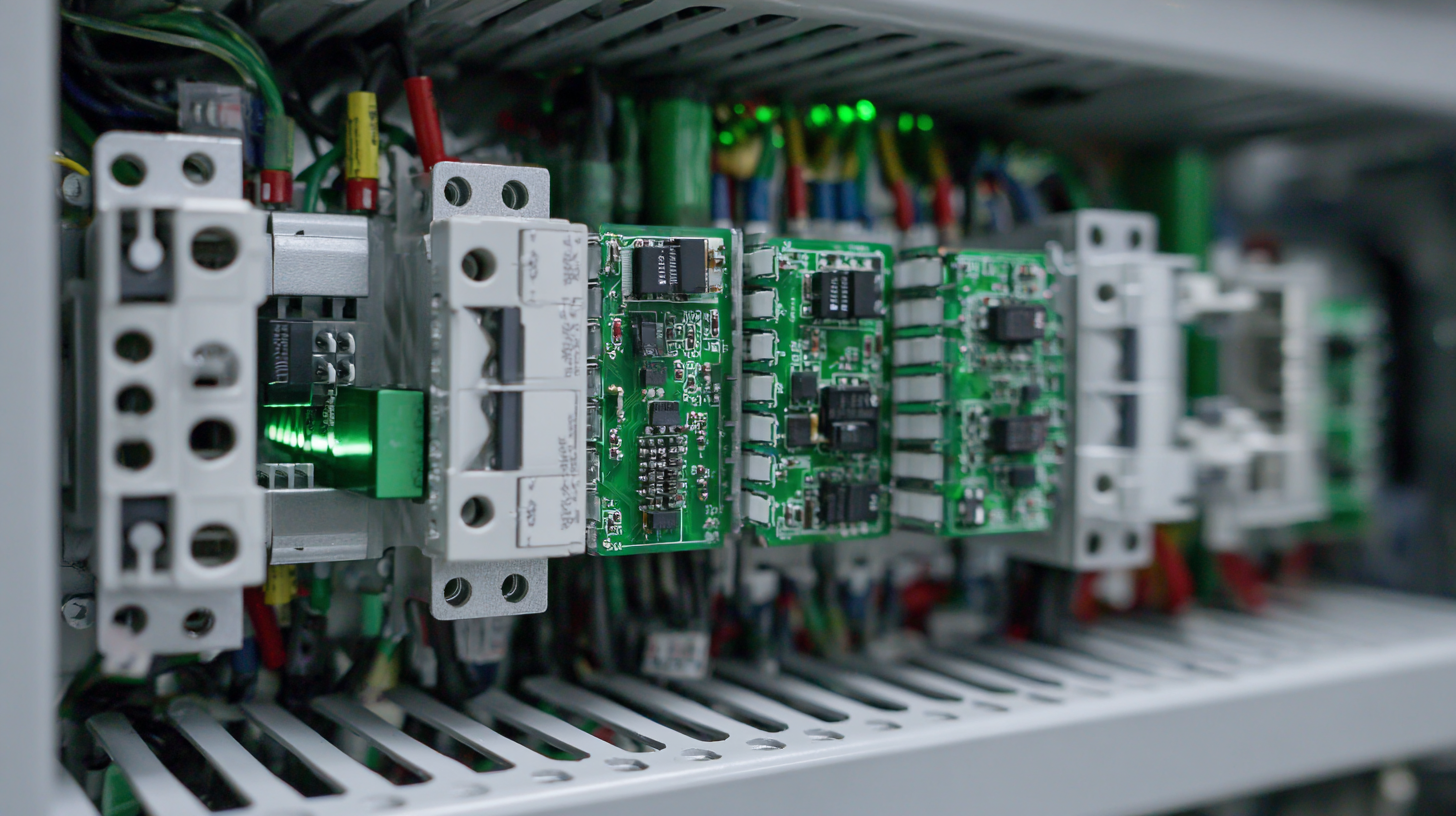

Common SCR Control Configurations in Electric Heaters

When it comes to electric heating, Silicon Controlled Rectifiers (or SCRs for short) have really become a game-changer for boosting efficiency. You see, most electric heaters use certain SCR control setups that allow for pretty precise control over temperature and power, which helps save energy and makes everything run smoother. These setups usually fall into a couple of categories—like phase control and burst-firing control. Each one has its own perks, depending on what kind of heating job you're dealing with. Basically, by using these controls, manufacturers can fine-tune how much power is delivered, fitting it exactly to the heating needs, which cuts down on wasted energy and keeps things running at their best.

At Jiangsu Weineng Electric Co., Ltd., we’ve got a solid background in designing and making explosion-proof electric heaters, and our experience with SCR control systems really sets us apart. We totally get how important it is to pick the right SCR setup to make sure your heater doesn’t just perform well but also stays safe—especially in tricky, hazardous environments. We’re dedicated to staying ahead with the latest SCR technology because it not only makes our products more reliable but also helps us deliver innovative solutions that match the changing needs of our industrial clients. By blending these ideas into our work, we help businesses run more efficiently and save money on their heating needs.

Industry Case Studies: Successful SCR Implementations

When it comes to making electric heaters more efficient, Silicon Controlled Rectifiers (or SCRs for short) have really become a game-changer. I’ve seen several real-world examples from top industries showing how switching to SCRs has led to big improvements—not just in performance, but also in saving energy. One example that sticks out is a large commercial building that decided to upgrade its heating system with SCRs. Instead of relying on old-school control methods, they used SCRs, and guess what? They cut their energy bills by about 30%, all while keeping the temperature just right in different zones. That kind of flexibility not only saved them money but also made the space way more comfortable for everyone inside. It’s a pretty cool proof of how SCR tech can really make a difference in everyday applications.

Then there’s another story from a manufacturing plant that used to struggle with temperature swings during busy hours. Once they added SCRs into the mix, they could tweak heating instantly in real-time, keeping everything at a steady, ideal temperature. This change meant less downtime and more output, which is a huge win. It really shows that SCRs are a smart investment for industries that depend on consistent heating. Overall, these examples highlight just how important SCR tech has become in modern electric heating systems—it’s definitely paving the way for smarter, more energy-efficient solutions across different sectors.

Future Trends in SCR Technology for Enhanced Energy Performance

As the world really starts to focus more on energy efficiency, Silicon Controlled Rectifiers—SCRs for short—are becoming pretty crucial in electric heating systems these days. If you look at recent industry chatter, the global SCR market is expected to grow at about 6.5% annually over the next five years. This growth is mainly fueled by ongoing improvements in semiconductor tech and how these devices are being used in sectors like HVAC and industrial heating. It’s exciting because this shift hints at a move towards smarter, more energy-friendly solutions that not only save money but also help cut down on environmental impact.

Looking ahead, SCR tech is getting better all the time to improve energy performance even more. For example, new innovations like advanced thermal management and better gate control are predicted to bump up heater efficiency by around 20%. And with the rise of IoT, these systems are now smarter—offering real-time monitoring and adaptive control, so users can fine-tune their energy use on the fly. According to a report from MarketsandMarkets, these kinds of energy-efficient tech could cut down energy wastage in industrial settings by about 30% by 2025. So, it’s clear SCRs aren’t just about saving costs—they’re playing a key role in building a greener, more sustainable future too.

Enhance Efficiency and Safety: The Role of Electric Air Heaters in Dust Removal for Power Stations

In recent years, the power generation industry has increasingly turned its attention toward enhancing operational efficiency and safety measures, particularly concerning dust removal processes. Electric air heaters have emerged as a pivotal solution in this realm, significantly improving the effectiveness of dust control systems in power stations. According to a report from the International Energy Agency (IEA), the effective management of particulate matter is crucial, as exposure to high levels of dust can lead to respiratory issues and machinery wear, costing the industry billions annually in maintenance and health-related expenses.

Electric air heaters play a vital role in dust removal by generating high-velocity warm air that effectively dislodges accumulated dust and particulates from surfaces and equipment. A study published in the Journal of Clean Energy Technologies noted that facilities equipped with electric air heating systems reported a 30% reduction in dust-related issues, leading to improved worker safety and decreased downtime. Furthermore, the integration of these heaters enables power stations to operate more sustainably, as they utilize less energy and produce lower emissions compared to traditional fossil fuel-based heating systems.

The benefits extend beyond mere dust removal; electric air heaters contribute to maintaining the overall functionality of equipment by preventing dust build-up, which can lead to operational inefficiencies. The U.S. Environmental Protection Agency (EPA) highlights that effective air heating systems can enhance air quality within power stations, thereby promoting a healthier work environment and compliance with environmental regulations. As power stations continue to prioritize safety and efficiency, the adoption of electric air heaters will likely become increasingly prevalent in their dust management strategies.

FAQS

: SCRs are used to enhance efficiency in electric heaters by enabling precise temperature management and power regulation, contributing to energy savings and improved performance.

The common SCR control configurations include phase control and burst-firing control methods, each tailored for different heating applications.

By utilizing SCR configurations, manufacturers can adjust power output to match specific heating demands, minimizing energy waste and ensuring optimal operation.

SCRs allow for more accurate temperature regulation and energy efficiency, leading to significant reductions in energy consumption and operational costs compared to traditional control methods.

Yes, the use of SCRs can enhance occupant comfort by ensuring precise temperature regulation across different zones in buildings.

SCR technology provides real-time adjustments to heating output, maintaining optimal temperatures which leads to increased productivity, reduced downtime, and overall better operational efficiency.

In a case study, the integration of SCRs resulted in a 30% reduction in energy consumption while improving temperature regulation across various zones.

SCRs address challenges related to heating fluctuations during peak operational hours, allowing for consistent heating and improved production efficiency.

The company leverages advanced SCR technology in their explosion-proof electric heaters to maximize efficiency and maintain safety standards in hazardous environments.

SCR technology is viewed as a valuable investment because it enhances efficiency, reduces costs, and improves the reliability and performance of heating systems across various industries.

Conclusion

In our guide, 'The Ultimate Guide to SCR Control for Electric Heaters,' we take a closer look at the pretty amazing technology behind SCR (that's Silicon Controlled Rectifier) control — and how it really boosts the efficiency of electric heating systems. If you’re into understanding how things work, we break down SCR technology and chat about the big perks, like using less energy and having much better control over the temperature. We also cover the usual setups of SCR control in electric heaters and share some eye-opening industry case studies that show how this tech is being successfully used in real-world scenarios.

On the industry side, Jiangsu Weineng Electric Co., Ltd. is a true standout. They’re leading the way with innovative, explosion-proof heating solutions that showcase the real potential of SCR technology. Looking ahead, we’re also excited to discuss some upcoming trends in SCR tech — things that will likely push energy efficiency even further and keep companies like Weineng right at the cutting edge of electric heater innovation.

Related Posts

-

Premium Electric Heater Solutions from China Your Trusted Global Manufacturing Partner

-

Exploring Innovative Alternatives: The Future of the Best Electric Process Heater for Global Buyers

-

Evaluating the Best Customized Industrial Heater Suppliers: A Comprehensive Comparison Guide

-

What is the Significance of Best Custom Immersion Heater in Industrial Applications

-

Exploring Unique Features of Industrial Heating Bundles and How to Select the Best Supplier

-

Essential Checklist for Obtaining the Best Industrial Heater Bundle Quotes

Blog Tags: