One of Hottest for Explosion Proof Process Heater - Constant Power / Constant Wattage trace heater – Weineng

One of Hottest for Explosion Proof Process Heater - Constant Power / Constant Wattage trace heater – Weineng Detail:

Feature

The heating value per unit length of the constant power heating belt is constant. The longer the heating belt used, the greater the output power. The heating tape can be cut to length according to actual needs on site, and is flexible, and can be laid close to the surface of the pipeline. The braided layer of the outer layer of the heating belt can play a role in heat transfer and heat dissipation, improve the overall strength of the heating belt, and also be used as a safety grounding wire.

Application

Generally used for heat tracing and insulation of small pipelines or short pipelines in pipe network systems

FAQ

1. Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2. What is difference between self regulating and constant wattage heat trace?

Pipe trace constant wattage has a higher temperature output and tolerance. It consumes more power so it requires a controller or thermostat and some types can be cut-to-length. Self-regulating cables have a lower temperature output and tolerance. They consume less power, but require larger breakers.

3. How many watts is heat trace?

The amount of primary heat required is proportional to the time required to achieve the final temperature. If one hour heat up requires 10 watts, then a two hour heat up requires 5 watts per hour for two hours. Conversely, a half hour heat up requires 20 watts to heat the system.

4. What is trace heating used for ?

Trace heating can be used to protect pipes and vessels from freezing by maintaining the temperature at a certain level above freezing point. This is done by supplying heat energy to balance the amount of heat lost through conduction.

Production Process

Markets & Applications

Packing

QC & Aftersales Service

Certification

Contact information

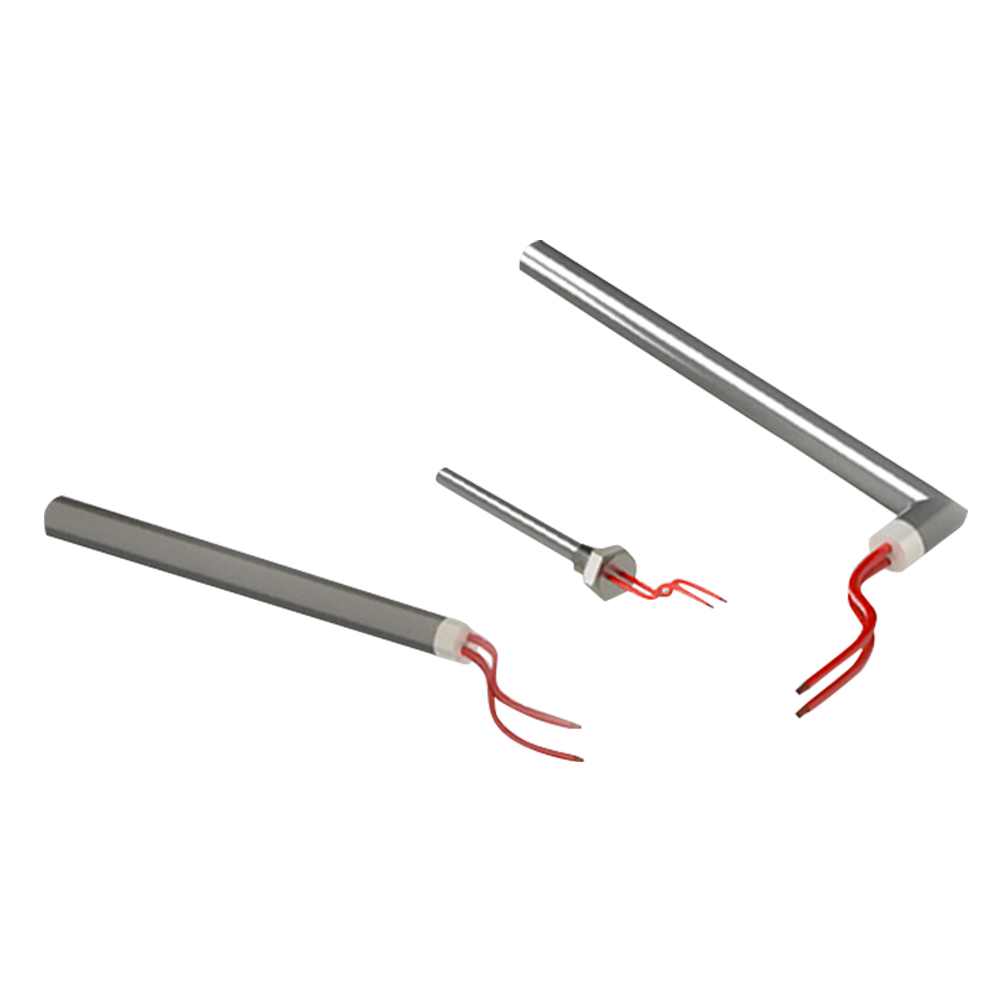

Product detail pictures:

Related Product Guide:

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for One of Hottest for Explosion Proof Process Heater - Constant Power / Constant Wattage trace heater – Weineng , The product will supply to all over the world, such as: Mauritius, belarus, Mali, We've established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we've been looking forward to even greater cooperation with overseas customers based on mutual benefits. You should feel free to contact us for more details.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!