Emerging Technologies for Industrial Flange Heater Solutions by 2025

Table of Contents

- Key Features to Look for in Flange Heater Technology by 2025

- Innovative Materials in Industrial Flange Heater Manufacturing

- Energy Efficiency: Enhancing Performance in Flange Heating Solutions

- Smart Technology Integration in Flange Heater Systems

- Safety Standards and Compliance for Modern Flange Heaters

- Future Trends Shaping the Industrial Heating Sector

- Choosing the Right Immersion Heater: What to Look for in a Manufacturer

- FAQS

- Related Posts

As the industrial world keeps leaning more and more on advanced tech solutions, it’s pretty clear that the demand for top-notch industrial flange heaters is about to skyrocket by 2025. A recent market report from Grand View Research predicts that the global market for industrial heating equipment will hit around USD 22.65 billion by then. A big part of this growth is really driven by a focus on safety and efficiency — no surprises there, right? Now, companies like Jiangsu Weineng Electric Co., Ltd. are really showing what’s possible. They’re seasoned pros when it comes to designing, making, and setting up explosion-proof electric heaters. Not only are they looking to be a big player in this rapidly growing market, but they’re also eager to expand beyond China and go global. With a strong commitment to quality and the latest tech, Weineng is definitely on track to win over customers everywhere, proving they’re serious about delivering excellent industrial heating solutions.

Key Features to Look for in Flange Heater Technology by 2025

As industries keep evolving, the need for more efficient flange heater technology is really becoming a top priority. By 2025, we’re actually expecting some pretty exciting advancements in this area, mainly driven by the push for better energy efficiency and smoother operations. According to a recent report from MarketsandMarkets, the global market for heating equipment is forecasted to jump from around $30 billion in 2022 to over $40 billion by 2025. That really shows how much emphasis there’s now on innovative solutions that can deliver higher efficiency without breaking the bank.

Innovative Materials in Industrial Flange Heater Manufacturing

The world of industrial flange heater manufacturing is changing pretty fast these days. Thanks to some really innovative new materials, performance and efficiency are getting a serious upgrade. By around 2025, we’re probably gonna see a big move toward using advanced composites and smart materials that not only boost thermal conductivity but also last longer and resist corrosion better. That means manufacturers can make flange heaters that stand up to extreme conditions, which cuts down on failures and helps keep maintenance costs in check.

On top of that, tiny tech like nanotechnology is making waves in material science. It’s opening doors to creating lighter, yet super durable parts. The result? More energy-efficient designs that transfer heat effectively but use less power — pretty cool, right? These cutting-edge materials will help industries meet tougher regulatory standards while also streamlining their operations. As more companies start adopting these new techs, we’ll probably see flange heaters popping up in all sorts of fields — from oil and gas to aerospace and even food processing. Honestly, it’s shaping up to change the game when it comes to industrial heating solutions.

Energy Efficiency: Enhancing Performance in Flange Heating Solutions

As industries keep evolving, it’s more important than ever to adopt energy-efficient solutions for flange heating. Looking ahead to 2025, we’re seeing new tech that’s really set to boost performance — think lower costs, less environmental impact. By bringing in smart materials and cutting-edge thermal management systems, companies can push their heating solutions to levels we haven't seen before in terms of energy efficiency.

Here’s a quick tip: consider retrofitting your current flange heating setups with modern insulation. It’s a pretty simple upgrade, but trust me, it can seriously cut down heat loss and save a bunch of energy, all while making your heater work better.

And don’t forget about the power of IoT sensors! These gadgets can give you real-time data, so you’re always in the know about what's happening. With this info, you can do predictive maintenance, optimize your heating cycles, and basically become smarter about your energy use. That means better efficiency and less waste.

Another tip — make sure your team gets trained on these new technologies and best practices. The more they understand, the better they can help you unlock the full potential of these upgrades. It’s really about making small changes that add up to big savings and a more eco-friendly operation.

Emerging Technologies for Industrial Flange Heater Solutions by 2025

This chart illustrates the projected energy efficiency improvements in flange heating solutions from 2023 to 2025. The data highlights the increasing performance due to emerging technologies.

Smart Technology Integration in Flange Heater Systems

You know, as smart technology keeps making its way into industrial flange heater systems, companies are really starting to get creative with new solutions to boost efficiency and performance. It’s kind of exciting — recently, we’ve seen some pretty cool advancements that aren’t just about getting the job done faster but also making things more comfortable for the folks on the receiving end. Take electric vehicles, for example.

Using high-tech radiant heaters to control cabin temperature really shows how better temperature management can make the ride more pleasant, and that can even help stretch the driving range and boost overall satisfaction.

According to industry reports, adopting smart heating setups in factories and industrial settings can cut energy use by as much as 30%. That’s pretty impressive, right? These systems use real-time data and machine learning to fine-tune heating patterns so that energy is only used when and where it’s really needed. It’s all part of this bigger trend towards automation and smarter systems — a shift we’re probably gonna see a lot more of by 2025.

Quick tip: When choosing flange heater systems, look for ones with smart tech built in — it can really help cut down on energy waste. Also, don’t forget that regular maintenance and software updates keep everything running smoothly. And if you pick a system with a simple, user-friendly interface, it’s way easier to keep an eye on things and adjust settings whenever you want.

Safety Standards and Compliance for Modern Flange Heaters

In today's world of industrial heating solutions, safety standards and compliance really matter when it comes to designing and deploying modern flange heaters. As industries move towards more automated and connected systems, the importance of strict safety protocols only grows. Organizations like the IEC and UL set regulations that help make sure the equipment can handle tough conditions without overheating or breaking down—that’s super important. Manufacturers now need to get their products certified to meet these standards, which is all about making sure things work reliably and safely.

But honestly, following safety standards isn’t just about ticking boxes; it also shows the manufacturer cares about quality and trustworthiness. Plus, lately, advanced flange heaters come with smart tech — stuff like intelligent temperature controls that can spot weird heating patterns as they happen. This real-time monitoring keeps things running smoothly and helps prevent accidents caused by faulty equipment. Looking ahead to 2025, it’s pretty clear that manufacturers will need to keep up with evolving safety rules and Blend these standards into their design process. That way, we can all look forward to safer, more reliable industrial setups.

Future Trends Shaping the Industrial Heating Sector

The industrial heating world is really starting to change fast, especially with new tech making big strides as we head into 2025. Just recently, a study pointed out that the heating hose market is actually looking pretty promising—demand’s expected to pick up and push things forward. It's a sign of bigger shifts happening, mainly because everyone’s putting more focus on being efficient and eco-friendly. Things like high-temperature heat pumps are becoming pretty much essential now, especially as industries push toward greener energy options. From what I’ve heard, the market for industrial heat pumps is set to grow quite a bit, and this just mirrors how more companies are looking for energy-efficient ways to manufacture.

If you’re thinking about jumping on these trends, a good move would be investing in innovative heating tech. It can boost your production and help you hit your sustainability targets at the same time.

On top of that, the rise of 3D printing is also going to shake things up big time in the industrial heating scene. Industry insiders have shared some interesting insights on how 3D printing impacts energy use and material choices in manufacturing. These advancements show that fine-tuning energy consumption with smarter heating solutions will be key, especially if companies want to stay compliant with regulations and keep up with what consumers are asking for.

Bottom line? Keeping up with these tech trends can really give your business a leg up. It’s worth thinking about strategic partnerships or investing in training so you can make the most of these new heating technologies without missing a beat.

Emerging Technologies for Industrial Flange Heater Solutions by 2025 - Future Trends Shaping the Industrial Heating Sector

| Technology | Expected Impact | Adoption Rate by 2025 | Key Benefits |

|---|---|---|---|

| Advanced Thermal Management Systems | Improved energy efficiency and reduced operational costs | 70% | Enhanced performance and lower emissions |

| Smart Sensors and IoT Integration | Real-time monitoring and predictive maintenance | 65% | Increased reliability and decreased downtime |

| Electrical Heat Tracing | Enhanced temperature control for process stability | 60% | Greater efficiency in heating components |

| Sustainable and Renewable Heating Solutions | Reduction of carbon footprint in industrial processes | 50% | Environmental compliance and energy savings |

| Automated Control Systems | Enhanced operational efficiency and safety | 75% | Reduced human error and increased production |

Choosing the Right Immersion Heater: What to Look for in a Manufacturer

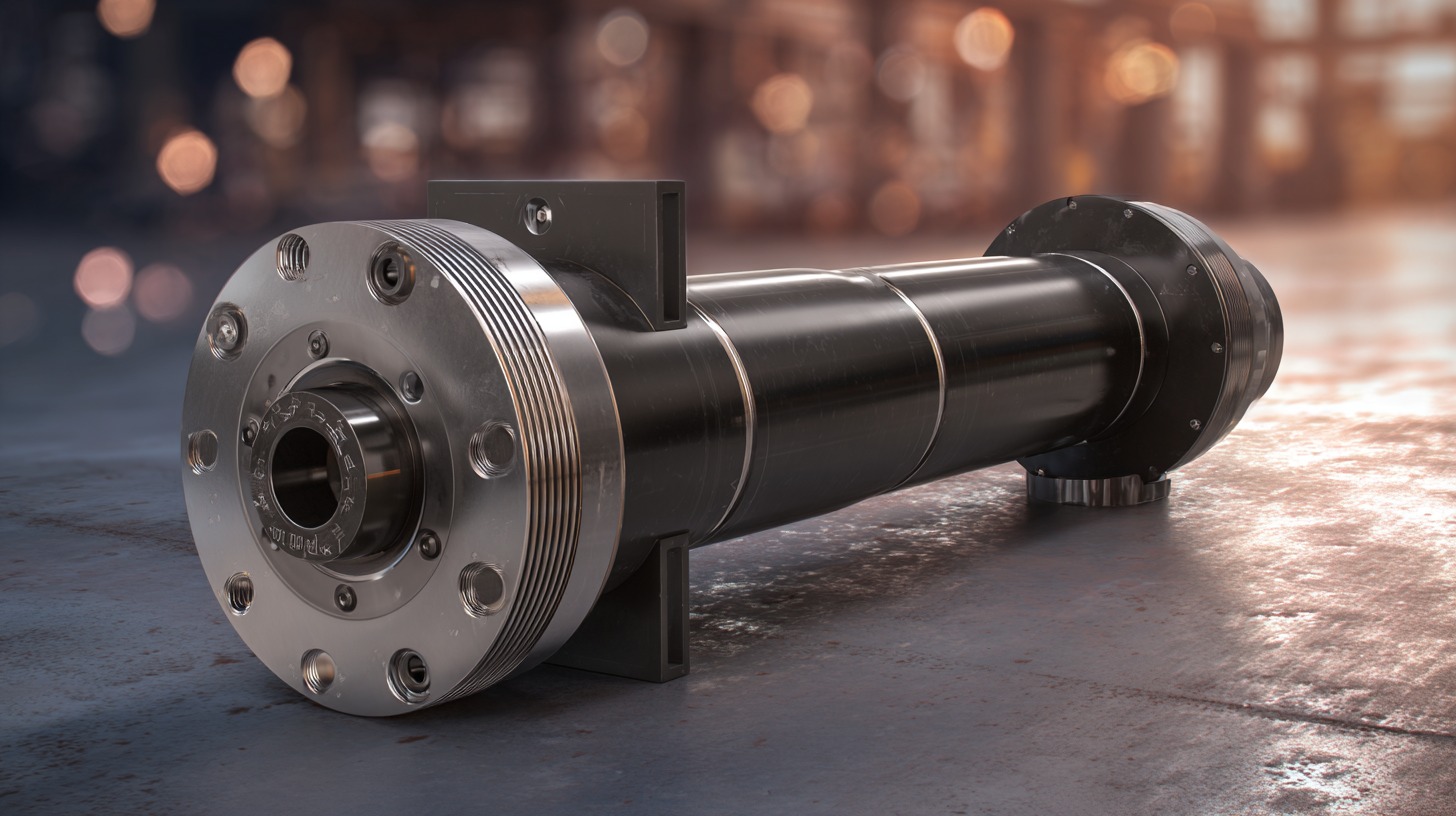

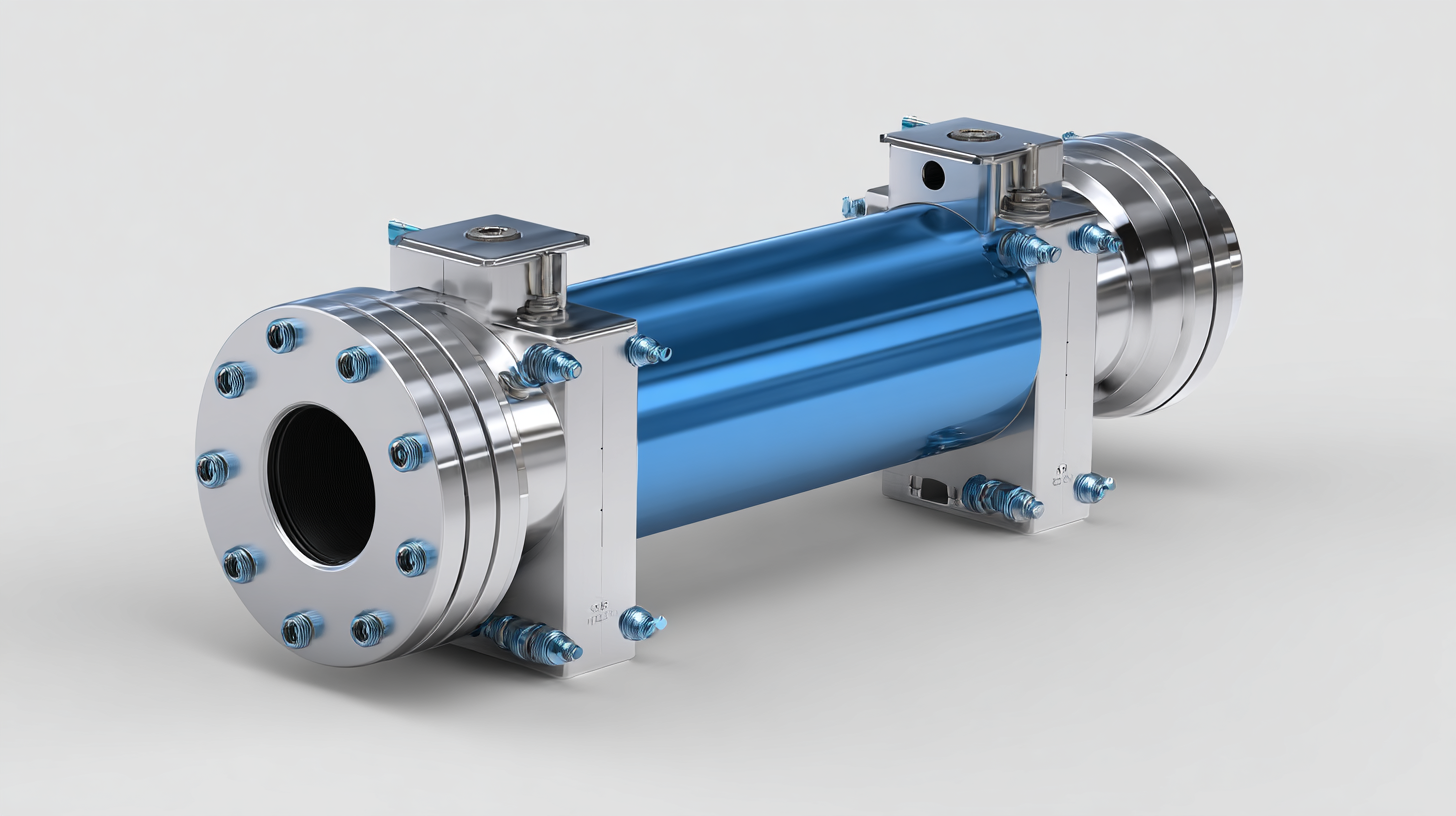

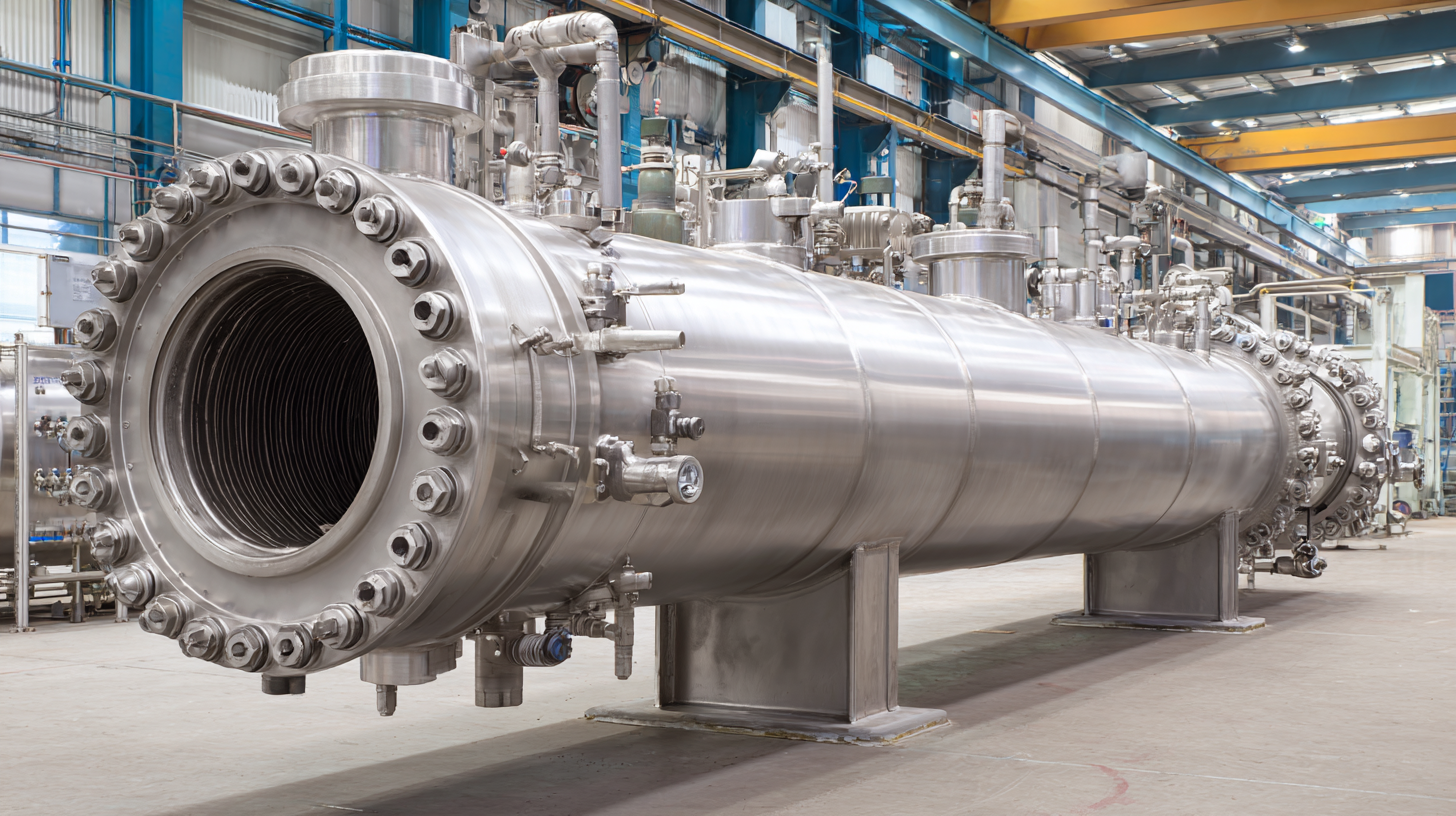

When selecting the right immersion heater, it is crucial to consider various factors that contribute to its efficiency and reliability, especially the manufacturer. Immersion heaters are designed to heat liquids, oils, or other viscous fluids by being installed directly in the tank that holds the fluid. This direct contact with the liquid allows for rapid and efficient heating, making immersion heaters a favored choice in various industrial applications.

Looking for a reputable manufacturer is vital, as it assures quality and durability. A good manufacturer will provide detailed specifications and robust customer support. It’s essential to evaluate the materials used in the heater's construction; high-quality materials are more resistant to corrosion and wear, which can significantly enhance lifespan and performance. Additionally, consider the heater’s compatibility with your specific application. Manufacturers that offer customizable options can ensure that the immersion heater meets your precise heating needs, whether for high-temperature liquids or specific tank sizes.

Moreover, the installation options provided by the manufacturer can significantly impact usability. A versatile manufacturer will offer a range of mounting solutions to accommodate various tank designs, thus improving the ease of installation and maintenance. By focusing on these key aspects when choosing an immersion heater manufacturer, you can ensure optimal performance and longevity for your heating systems, leading to better operational efficiency.

FAQS

: Innovative materials such as advanced composites and smart materials are being used, which enhance thermal conductivity, durability, and corrosion resistance.

Nanotechnology allows for the creation of lightweight yet robust components, leading to more energy-efficient designs and improved heat transfer with reduced energy consumption.

Industries such as oil and gas, aerospace, and food processing are expected to see broader applications of flange heaters due to advancements in materials and technologies.

The industrial heat pump market is anticipated to experience notable growth, reflecting a trend towards energy-efficient manufacturing and green energy initiatives.

Companies should invest in innovative heating solutions that enhance production efficiency while also focusing on sustainability to meet regulatory standards.

3D printing is expected to influence energy consumption and material strategies, prompting a need for optimizing energy use through modern heating solutions for regulatory compliance.

Staying ahead of trends can provide competitive advantages, allowing businesses to enhance production efficiency and adapt to consumer demands.

There is an increasing emphasis on efficiency and sustainability, driving the adoption of technologies like high-temperature heat pumps and innovative heating solutions.

The use of advanced materials in flange heater manufacturing significantly reduces the risk of failure and minimizes maintenance costs, leading to improved operational efficiency.

Strategic partnerships and investments in training can help businesses leverage new industrial heating technologies effectively, staying competitive in a rapidly evolving market.

Related Posts

-

Innovative Solutions for Industrial Heating Challenges in Manufacturing Environments

-

Exploring Unique Features of Industrial Heating Bundles and How to Select the Best Supplier

-

Premium Electric Heater Solutions from China Your Trusted Global Manufacturing Partner

-

Exploring Innovative Alternatives: The Future of the Best Electric Process Heater for Global Buyers

Blog Tags: