Innovative Solutions for Industrial Heating Challenges in Manufacturing Environments

Table of Contents

- Emerging Trends in Industrial Heating Technologies for Manufacturing

- The Role of Quality Control in Industrial Heating Systems

- Energy Efficiency Solutions for Sustainable Manufacturing Heating

- Case Studies: Innovative Heating Applications in Chinese Manufacturing

- Future Outlook: The Evolution of Industrial Heating in Global Markets

- Top Considerations When Choosing the Right Immersion Heater Manufacturer for Your Needs

- FAQS

- Related Posts

You know, in the hustle and bustle of the manufacturing world, tackling those industrial heating issues is super important for keeping everything running smoothly and safely. Recent reports are saying that the global market for industrial heating could hit a whopping $25 billion by 2026, and that's mainly because everyone’s craving energy-efficient and high-tech heating solutions these days.

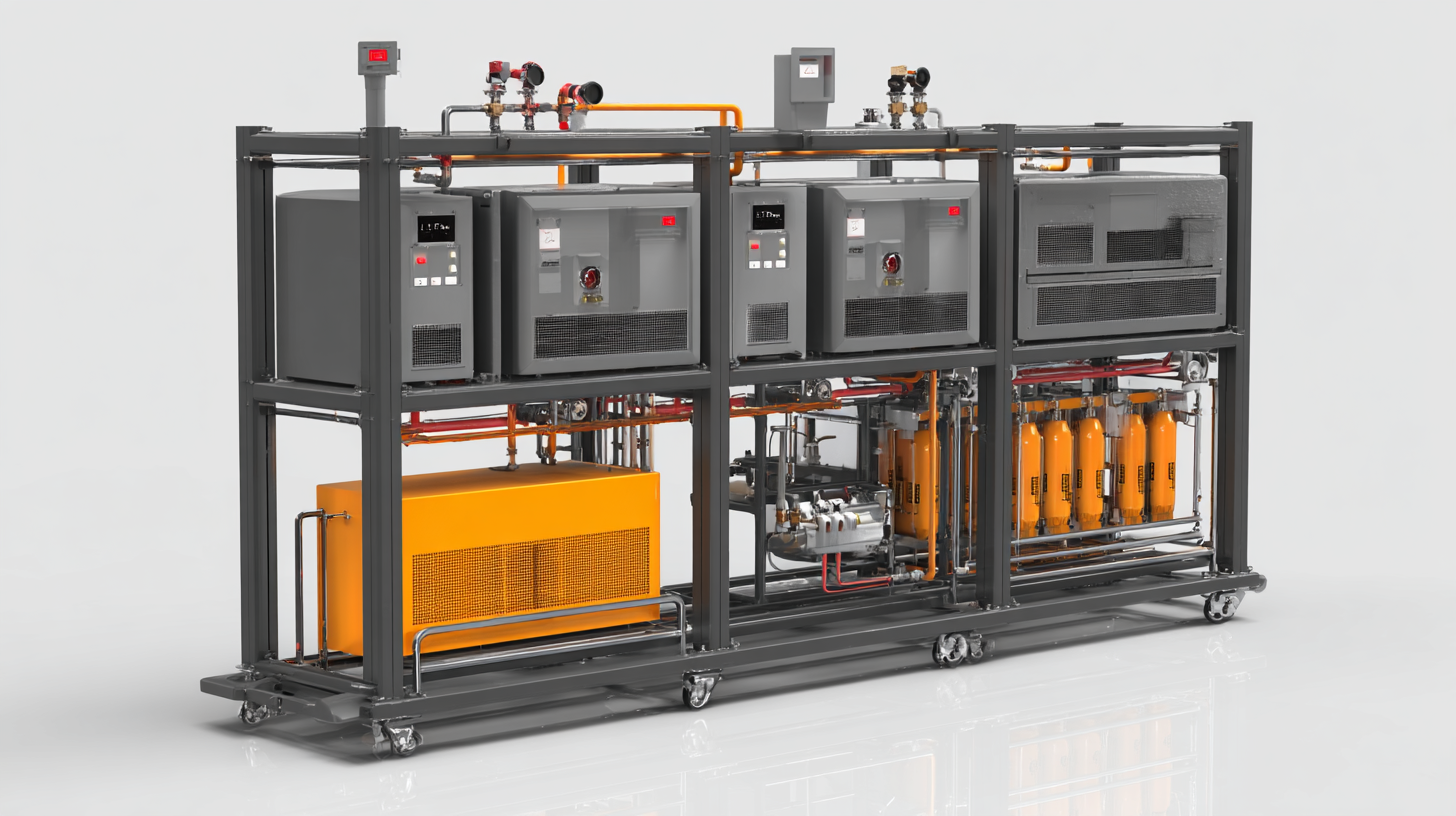

One company really standing out in this space is Jiangsu Weineng Electric Co., Ltd., a top-notch manufacturer of electric heaters based in China. They really know their stuff when it comes to designing and producing explosion-proof electric heaters, which is crucial for handling these heating challenges. With their innovative designs, they not only boost productivity but also stick to those strict safety standards, making them a go-to partner for manufacturers eager to enhance their heating systems.

Having spent years fine-tuning their approach and offering tailored heating solutions, Weineng is all geared up to meet the unique needs of different manufacturing settings, ensuring that efficiency and safety are always front and center in industrial processes.

Emerging Trends in Industrial Heating Technologies for Manufacturing

You know, the latest trends in industrial heating tech are really shaking things up in manufacturing. They're totally changing the game when it comes to energy efficiency and optimizing those processes. A recent report by the U.S. Department of Energy pointed out that about 30% of the energy used in manufacturing goes straight to heating. That's a big deal! It highlights how crucial it is for businesses to come up with innovative solutions that not only boost performance but also cut down on energy use. With new technologies like induction and infrared heating making waves, manufacturers can actually speed up processing times while trimming energy waste.

One exciting trend is the rise of smart heating systems that tap into IoT and AI for real-time monitoring and control. These smart systems can ramp up heating efficiency quite a bit—some studies show they can slash energy use in industrial heating by up to 25%! So, for manufacturers who hop on this train, it's not just about saving money; they’re also playing their part in sustainability efforts.

**Here are a few tips for getting started**:

1. Think about retrofitting your existing heating systems with smart controls to boost efficiency.

2. Look into whether switching to induction heating methods makes sense for your specific needs since they heat up super quickly and waste less energy.

3. Don't forget to perform regular energy audits to find potential areas for improvement in your heating processes—keeping systems at their best is key!

The Role of Quality Control in Industrial Heating Systems

You know, when it comes to industrial heating systems, quality control really makes a huge difference in how well things run and the reliability of the products. A report by the American Society of Mechanical Engineers (ASME) even points out that around 30% of energy costs in manufacturing come from heating processes. Isn’t that just wild? It really highlights why having solid quality control in place is so crucial. By sticking to some thorough testing protocols and performance checks, manufacturers can cut down on energy use and waste like it’s nobody’s business.

But it’s not just about saving energy—quality control also has a big impact on the actual quality of the products and how consistent they are. The International Organization for Standardization (ISO) has found that when systems don’t have proper quality checks, defect rates can shoot up by as much as 15%. That’s a lot! Using advanced monitoring like thermographic inspections and automated data collection helps keep everything running smoothly and can spot problems right away. By bringing in this tech, we not only boost the reliability of those heating systems but also help manufacturers move towards predictive maintenance. This means less downtime and better overall productivity. Pretty cool, right?

Energy Efficiency Solutions for Sustainable Manufacturing Heating

You know, in today’s manufacturing world, energy efficiency has really become a big deal. It’s not just about cutting down costs; it’s also about doing our part for the planet. We’re seeing some really cool innovations in heating solutions that tackle the tough challenges of industrial heating, helping to slash energy consumption by quite a bit. A lot of these new advancements use smart tech that keeps an eye on heating processes in real-time, making sure we’re using energy wisely without any waste.

One of the trends I find particularly exciting is the use of advanced insulation materials and systems. They’re great because they help to cut down on heat loss, which means manufacturers can have better control over temperatures while also reducing how much energy they need. Plus, there are heat recovery systems that let companies capture and reuse heat that gets generated during production, which is a fantastic way to boost energy efficiency. As manufacturers get more focused on being sustainable, these innovative solutions are not only helping them meet environmental regulations but also building a positive culture around sustainability that really clicks with consumers and stakeholders.

Energy Efficiency Solutions for Sustainable Manufacturing Heating

This chart illustrates the energy efficiency improvements achieved through various innovative heating solutions in manufacturing environments. The data reflects the average percentage reduction in energy consumption across different heating technologies used in industrial settings.

Case Studies: Innovative Heating Applications in Chinese Manufacturing

You know, over the last few years, China’s manufacturing sector has really stepped up its game, especially when it comes to industrial heating solutions—thanks to some pretty cool new tech. Take carbon nanotube technology, for instance. It’s expected to make quite an impact, with the global market jumping from $7.75 billion in 2025 to a whopping $18.98 billion by 2032. That’s a compound annual growth rate of 13.6%! It’s amazing how much these high-performance materials are becoming essential for boosting energy efficiency and cutting down costs in manufacturing.

A standout project that really shows off this innovation is a new boiler system that uses flue gas-based molten salt energy storage. How cool is that? This groundbreaking approach tackles the big issue of energy management in factories, making energy use way more efficient while also slashing carbon emissions. The success of this technology is really part of a bigger shift—industries are aligning more with government goals focused on sustainability and innovation.

In fact, the government's 2025 work report is all about blending scientific advances with industrial growth, pushing for not just new industries to rise but also transforming old-school sectors into more modern and efficient production lines.

Future Outlook: The Evolution of Industrial Heating in Global Markets

When we look ahead, the future of industrial heating in global markets seems pretty bright! It's clear we're in for some significant growth and change, mostly thanks to new technologies and a big push towards energy efficiency. Take the global combined heat and power (CHP) market, for example—it's projected to jump from $19.06 billion in 2025 to around $30.38 billion by 2032. That’s a solid annual growth rate of about 6.89%! This surge really highlights how companies are investing more and more in sustainable energy solutions. Manufacturers, in particular, are keen to cut their carbon footprints while still keeping their operations running smoothly.

On a similar note, the pipeline industrial heater market is expected to cross the $2.3 billion mark in 2024, with a compound annual growth rate (CAGR) of 5.1% forecasted from 2025 to 2034. This growth is really being driven by smart heating technologies and a greater emphasis on sustainability. And let’s not forget about the industrial heat pump market; it’s set to become quite significant too, with projections estimating its size at around $290 billion by 2032. That’s a CAGR of 6.37% starting in 2024! All these numbers tell us one thing: as industries around the globe adjust to this new energy landscape, we can expect innovative heating solutions to be key players in building more efficient and sustainable manufacturing environments.

Top Considerations When Choosing the Right Immersion Heater Manufacturer for Your Needs

Choosing the right immersion heater manufacturer is crucial for optimizing efficiency and ensuring the longevity of your heating solutions. Immersion heaters, which directly heat liquids, oils, or other viscous fluids, are essential in various industrial applications. According to a recent industry report, the global immersion heater market is projected to reach approximately $2 billion by 2026, highlighting the growing demand for efficient heating solutions.

When selecting a manufacturer, consider their expertise in producing immersion heaters tailored to your specific needs. Look for companies that provide customizable options for immersion heaters, as these can be installed in a variety of configurations in heating tanks. It's essential to evaluate their product range, focusing on materials, power ratings, and the types of fluids they can effectively heat. Research indicates that manufacturers with a proven track record in supplying tailored solutions often yield better energy efficiency and lower operational costs.

Another critical factor is compliance with safety standards and regulations. A reputable manufacturer will ensure that their immersion heaters are built to meet industry guidelines, reducing the risk of malfunctions and potential hazards. Reports show that organizations prioritizing safety and reliability in their heater selection process often experience fewer downtime incidents and improved overall operational efficiency. Be sure to assess the manufacturer’s commitment to quality assurance and customer support to guarantee a successful partnership.

FAQS

: Approximately 30% of energy used in manufacturing processes is attributed to heating.

Smart heating systems that leverage IoT and AI for real-time monitoring and control can significantly improve heating efficiency, potentially reducing energy use by up to 25%.

Retrofitting existing heating systems with smart controls can enhance efficiency, lower operational costs, and contribute to sustainability goals.

Innovative heating solutions include the adoption of advanced insulation materials, smart technologies for real-time monitoring, and heat recovery systems for reusing generated heat.

The global combined heat and power (CHP) market is forecasted to expand with a robust annual growth rate of 6.89%, from $19.06 billion in 2025 to $30.38 billion by 2032.

The pipeline industrial heater market is expected to exceed $2.3 billion in 2024, with a compound annual growth rate (CAGR) of 5.1% projected from 2025 to 2034.

Energy efficiency is crucial for reducing operational costs and minimizing environmental impact, helping manufacturers comply with regulations and foster a culture of sustainability.

Advanced insulation materials help minimize heat loss, allowing for greater temperature control and lowering energy requirements in manufacturing processes.

The industrial heat pump market is expected to reach $290 billion by 2032, reflecting a compound annual growth rate (CAGR) of 6.37% from 2024 onwards.

Blog Tags: