Revolutionizing Heat: How Industrial Oil Heaters Enhance Efficiency in Modern Industries

Table of Contents

- Understanding Industrial Oil Heaters and Their Mechanisms

- The Role of Efficiency in Modern Industrial Processes

- Comparative Analysis: Oil Heaters vs. Alternative Heating Methods

- Benefits of Using Industrial Oil Heaters in Various Industries

- Case Studies: Successful Implementation of Oil Heating Solutions

- Future Trends in Industrial Oil Heating Technology

- Essential Guide to Choosing the Right Industrial Thermal Oil Heater for Optimal Efficiency and Safety

- FAQS

- Conclusion

- Related Posts

These days, with everything in the industrial world changing so fast, staying efficient is pretty much the key to success. One technology really making waves in this space is the Industrial Oil Heater. These modern heating systems don't just boost energy efficiency—they also deliver reliable, consistent heat that's essential for all sorts of industrial processes.

Here at Jiangsu Weineng Electric Co., Ltd., we’re really proud to be a high-tech company that specializes in designing and making explosion-proof electric heaters. With years of hands-on experience in production and startup testing, we're constantly pushing innovation. That’s why our Industrial Oil Heaters are honestly some of the best out there. By using these advanced heating solutions, today’s industries can cut down on operational costs and get more done—really changing the game when it comes to managing heat and hitting new levels of efficiency.

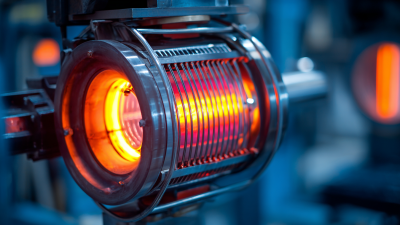

Understanding Industrial Oil Heaters and Their Mechanisms

You know, industrial oil heaters have really become a must-have in today’s industries. They’re super useful because they help improve efficiency by managing heat more effectively. When you really understand how they work, you start to see just how many advantages they bring to the table. Basically, they transfer heat efficiently to various industrial processes — which is a big deal whether you’re making food, producing chemicals, or doing other heavy-duty stuff. And it’s pretty cool to see how new tech, like microwave-assisted heating or new methods for removing heat, can make a big difference — boosting yields and upping the quality of the end products.

Plus, when you look into different pyrolysis methods, it’s clear that oil heaters play a pretty important role in turning biomass into bio-oil. They’re also key when it comes to extracting valuable things like essential oils and biochar more effectively.

Nowadays, as industries push for more sustainable practices, using the latest heating tech becomes more than just a smart move — it’s almost a necessity. It helps make better use of resources and cuts down on waste. By really understanding how these systems work, companies can totally transform how they do things, making their operations more efficient and eco-friendly. It’s pretty exciting to see how this all evolves!

The Role of Efficiency in Modern Industrial Processes

When we talk about Industry 5.0, efficiency really becomes the star of the show. As industrial processes adapt with cutting-edge tech, the focus isn't just on working faster or producing more, but also on doing so in a way that's better for our planet. Think about it—recent studies suggest that adding smart automation and advanced control systems can bump up efficiency by as much as 30%. That means less waste, lower energy bills, and a more sustainable way of getting things done.

Now, to actually achieve these kinds of efficiency levels, you need a solid plan. One important piece of the puzzle is using industrial oil heaters — they play a crucial role in keeping temperatures just right across various manufacturing steps. When used properly, these heaters can even cut energy use by around 20%, which is pretty awesome. It’s a win-win: you meet your production targets and also help make operations greener.

Pro tip: Make sure to stick to regular maintenance routines for your heating equipment. And, if you can, invest in smart monitoring systems. They’ll help you track how everything's performing and spot areas that could use improvement. Basically, data-driven decisions can lead to some serious boosts in productivity and energy savings — it’s worth it!

Comparative Analysis: Oil Heaters vs. Alternative Heating Methods

When you're looking into industrial heating options, oil heaters really tend to stand out — mainly because they’re super efficient and effective, especially when you compare them to stuff like electric or gas heating. A recent report from the Energy Efficiency Analytical Panel pointed out that oil heaters can hit thermal efficiencies of over 90%. That’s a pretty big deal, considering most traditional electric heaters often don’t go above 80%. What does that mean in everyday terms? Well, it’s more fuel saved and cheaper operation costs, which makes oil heaters a smart choice, especially for industries where energy use is a big deal.

Plus, these oil heaters are pretty versatile and adaptable for all kinds of industrial setups. According to a study from the Industrial Heating Association, they can work effectively across a wide range of temperatures — making them suitable for all sorts of manufacturing processes. On the other hand, gas heating systems might not offer the same level of temperature control and consistency, which is kinda crucial for modern industries. As more companies focus on saving energy and cutting down operational costs, the advantages of oil heaters become even more compelling. All in all, they’re shaping up to be a key player in the future of industrial heating solutions.

Benefits of Using Industrial Oil Heaters in Various Industries

You know, industrial oil heaters are really becoming more and more important across different sectors these days. It’s kind of a reflection of how everyone’s now trying to get smarter about saving energy. Companies looking to boost their operations are finding that oil heaters can do quite a bit — like keeping temperatures steady and warming things up quickly. And honestly, that means using less energy overall, which is a big deal with energy costs on the rise and all the talk about being more eco-friendly.

Looking at the market outlook, it’s pretty exciting. Experts say the global market for heating equipment will jump from around $115 billion in 2025 to approximately $172 billion by 2032. That’s a solid growth rate of about 5.8% each year. A big part of this growth comes from new, smarter heating tech — like these oil heaters — which not only work better but also cut down on waste and pollution. That’s especially important for industries like manufacturing, food processing, and chemicals, who are really eager to stay ahead by being more efficient and greener at the same time.

Case Studies: Successful Implementation of Oil Heating Solutions

In today’s industrial world, using advanced oil heating systems has really made a difference when it comes to boosting efficiency and getting more done. Take, for example, a leading food processing company that switched to cutting-edge industrial oil heaters — they saw about a 30% drop in their energy bills! By upgrading to more optimized thermal oil setups, they didn’t just make their heating process smoother; they also kept their product quality intact during thermal treatments. It’s a pretty good example of how innovation in heating tech can actually save a lot of money and improve operations.

And it’s not just in food processing. The petrochemical industry’s got its own success story. One big refinery adopted new oil heating solutions and ended up increasing its overall efficiency by around 25%. The upgrade made it easier for them to control temperatures more precisely and turn things around faster, which is crucial for staying competitive. According to a 2022 report from the International Energy Agency, companies that jump on these advanced heating technologies—like oil heaters—can see energy efficiency improvements of up to 40%. So, overall, it’s clear that these solutions hold some pretty powerful potential for all kinds of industries.

Future Trends in Industrial Oil Heating Technology

Looking ahead, the future of industrial oil heating is definitely heading toward some pretty exciting advancements. As industries push for better energy efficiency and sustainability, we're seeing trends that really highlight the integration of smart tech and automation into these systems. Things like real-time monitoring and control are becoming more common, helping to optimize heating and cut down on energy waste. Thanks to IoT devices, companies can now gather data on things like temperature changes and oil consumption, which means better performance and lower costs all around.

On top of that, there's a noticeable shift towards eco-friendly oil options. More companies are starting to use bio-based oils or synthetic alternatives that aim to reduce carbon footprints without sacrificing heat efficiency. This move isn’t just about being greener — it’s also in line with global sustainability efforts and tougher regulations for cleaner operations. As everything keeps evolving, it seems like the mix of high-tech solutions and greener choices will really change how we look at oil heating. Overall, it’s about making industrial heating more efficient, responsible, and better for the planet.

Essential Guide to Choosing the Right Industrial Thermal Oil Heater for Optimal Efficiency and Safety

When it comes to selecting the right industrial thermal oil heater, efficiency and safety should be at the forefront of your decision-making process. Among the various options available, the industrial electric thermal oil heater stands out due to its ability to provide consistent and reliable heating. Unlike traditional heating methods, electric thermal oil heaters operate with minimal emissions and can achieve high temperatures without the need for combustion. This not only reduces the environmental impact but also minimizes safety hazards associated with gas and oil combustion.

Moreover, electric thermal oil heaters are renowned for their advanced control systems that ensure precise temperature regulation, making them ideal for processes that require exact thermal conditions. Their design allows for quick warm-up times and reduced downtime, which ultimately boosts overall efficiency in industrial operations. Additionally, their compact size and modular design can significantly save space while offering easy installation and maintenance, which is essential in busy industrial settings. By focusing on these aspects, choosing an industrial electric thermal oil heater contributes to both optimal operational efficiency and enhanced safety measures in your facility.

FAQS

: Industrial oil heaters are used to enhance efficiency through effective thermal management, critical for applications ranging from food production to chemical synthesis.

They operate by efficiently transferring heat to industrial processes, optimizing heating processes to improve yield and quality.

Significant advancements include the integration of smart technologies and automation, enabling real-time monitoring and control for optimizing heating processes.

IoT devices allow industries to gather and analyze data on temperature fluctuations and oil usage, leading to enhanced performance and lower operational costs.

Oil heaters facilitate better resource utilization and minimize waste, aligning with the growing focus on sustainability in industrial operations.

Companies are increasingly adopting bio-based oils and synthetic options that minimize carbon footprints while maintaining high thermal efficiency.

The future will see more advancements in energy efficiency, the adoption of environmentally friendly alternatives, and the integration of smart technologies.

Optimizing heating processes can lead to significant improvements in the extraction of valuable components, enhancing both yield and quality in production.

Advanced heating solutions help to reduce energy waste, lower operational costs, and support cleaner, more efficient industrial practices.

This convergence is set to redefine the use of oil heaters, promoting a more efficient and eco-conscious industrial environment.

Conclusion

Industrial oil heaters are pretty important when it comes to boosting efficiency in modern industries, especially by optimizing thermal processes. Once you get how they work — like how they transfer heat effectively — you see why they’re so valuable for all kinds of applications. Nowadays, there’s a lot of focus on making operations more efficient, and that’s led many to compare different heating options. It turns out that oil heaters often have the edge over alternatives like electric or gas heating solutions.

Plus, these heaters come with quite a few perks. They help make better use of energy, cut down on operational costs, and are super versatile — perfect for a bunch of different sectors. We also see many real-world examples through case studies showing just how well they perform in practice. Looking ahead, as technology keeps evolving, the future of industrial oil heating systems looks really promising — we can expect even cooler innovations that match the changing needs of industries.

Here at Jiangsu Weineng Electric Co., Ltd., we’re super dedicated to pushing these solutions forward. We bring our expertise to the table, designing and manufacturing safe, dependable oil heating tech that's suitable for a wide range of uses.

Related Posts

-

The Essential Ultimate Guide to Choosing the Best Explosion Proof Industrial Heater Suppliers

-

Evaluating the Best Customized Industrial Heater Suppliers: A Comprehensive Comparison Guide

-

7 Essential Tips to Choose the Right China Industrial Heating Bundle Suppliers

-

How to Choose the Right China Customized Industrial Heater Manufacturers for Your Business Needs

-

7 Tips to Choose the Right China Explosion Proof Industrial Heater for Your Business

-

7 Essential Tips for Choosing the Right Explosion Proof Industrial Heater Manufacturer

Blog Tags: