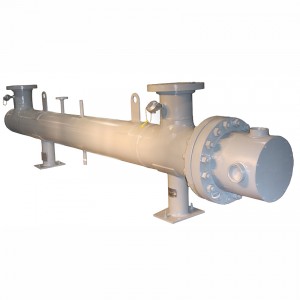

industrial thermal oil heater

The electric thermal oil heater is a new type, energy-saving, special industrial furnace that can provide high-temperature heat. The heat is generated and transmitted by electric heating elements immersed in the heat-conducting oil, and the heat-conducting oil is the heat carrier. Use the heat transfer oil as the medium, use the circulating pump to force the heat transfer oil to circulate in the liquid phase, and transfer the heat to one or more heat-using equipment. After the heat-used equipment is unloaded, it passes through the circulating pump again to the heater and absorbs The heat is transferred to the heat-using equipment, so that the continuous transfer of heat is realized, and the temperature of the heated object is increased to meet the heating process requirements.

The heat conduction oil heater is mainly used for the heating of crude oil, natural gas and the processing, storage and transportation of mineral oil in the industry. The oil refinery utilizes the waste heat of heat transfer oil to cool the material, and it has been successfully used to heat the solvent and extractant evaporation device in the lubricant manufacturing process.

In the chemical industry, it is mainly used for distillation, evaporation, polymerization, condensation/demulsification, fatification, drying, melting, dehydrogenation, forced moisture retention, and heating of synthetic equipment such as pesticides, intermediates, antioxidants, surfactants, and fragrances.

1.Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2.What are the available product certifications?

We have certifications such as: ATEX, CE, CNEX. IS014001, OHSAS18001,SIRA, DCI. Etc

3.What are the available heater pressure ratings?

WNH process flange heaters are available in pressure ratings from 150 psig (10 atm) to 3000 psig (200 atm).

4.What is the maximum design temperature?

Design temperatures up to 650 °C (1200 °F) are available based on customer specifcations.

5.What type of temperature sensors are provided with the heater?

Each heater is provided with temperature sensors at the following locations:

1) on the heater element sheath to measure maximum sheath operating temperatures,

2) on the heater fange face to measure maximum exposed surface temperatures, and

3) An Exit temperature measurement is placed on the outlet pipe to measure the temperature of the medium at the outlet. The temperature sensor is a thermocouple or PT100 thermal resistance, according to customer requirements.