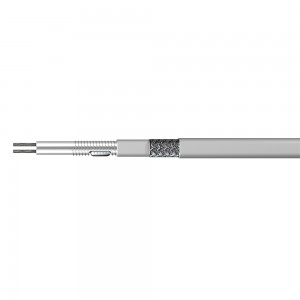

Constant wattage trace heater for industry

The heating value per unit length of the constant power heating belt is constant. The longer the heating belt used, the greater the output power. The heating tape can be cut to length according to actual needs on site, and is flexible, and can be laid close to the surface of the pipeline. The braided layer of the outer layer of the heating belt can play a role in heat transfer and heat dissipation, improve the overall strength of the heating belt, and also be used as a safety grounding wire.

In addition to the characteristics of a single-phase heating cable, the three-phase heating cable also has the following characteristics:

1. The maximum allowable length of a three-phase heating belt with the same power is three times that of a single heating belt

2. The three-phase belt has a large cross section and a large heat transfer area, which can improve the transmission efficiency.

Generally used for heat tracing and insulation of small pipelines or short pipelines in pipe network systems.

The three-phase parallel tape is generally suitable for heat tracing and insulation of large pipe diameters, pipe network system pipelines and tanks.

1.Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2.Will heat tape thaw frozen pipes?

Every few minutes check on the pipe to see if it is unfrozen. Once that portion has thawed, move the heater to the new section of the frozen pipe. Another way to thaw pipes is to buy and use electric heat tape on the frozen pipes. Place the electric tape on the affected pipe and wait for it to thaw out slowly.

3.When installing heating cable fasten the cable to the pipes using fiberglass tape or?

Fasten the heating cable to the pipe at 1 foot intervals using fiberglass tape or nylon cable ties. Do not use vinyl electrical tape, duct tape, metal bands or wire. If there is excess cable at the end of the pipe, double remaining cable back along the pipe.

4.How much resistance should heat trace have?

Minimum readings of 20 M Ohms for each circuit is an acceptable level to test for. A record should be kept of the reading after the cable has been installed. This reading can be used as a reference point when taking future readings during regular maintenance.

5.Can heat trace be repaired?

Having to repair your trace cable is an extremely rare occurrence. ... The SKDG Cable Repair Kit is intended to be used to repair dual and single conductor construction EasyHeat Snow Melting mats and cable kits, thermal storage and radiant heating mats damaged either during installation or subsequent operation.