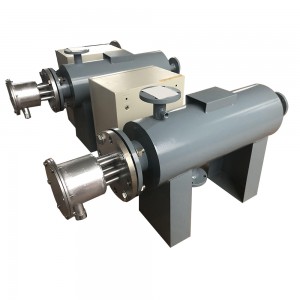

Electric Nitrogen Heater

Nitrogen heaters are designed to address the specific needs that come with heating nitrogen. They help keep processes safe, efficient, and cost-effective.

Nitrogen heaters are used in a variety of industries. Some of the notable applications include:

Polysilicon manufacturing

Solar photovoltaic manufacturing

Rocket facilities

Chemical Industrial

1.Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2.What are the available product certifications?

We have certifications such as: ATEX, CE, CNEX. IS014001, OHSAS18001,SIRA, DCI. Etc

It is important to consider the specifics of your application prior to selecting the heater to use. Of primary concern is the type of medium being heated and the amount of heating power required. Some industrial heaters have been specially designed to function in oils, viscous, or corrosive solutions.

However, not all heaters can be used with any material. It is important to confirm the desired heater will not be damaged by the process. In addition, it is necessary to select an electric heater that is appropriately sized. Be sure to determine and verify the voltage and wattage for the heater.

One important metric to consider is Watt Density. Watt density refers to the heat flow rate per square inch of surface heating. This metric shows how densely the heat is being transferred.

4.What are electrical controls?

An electrical control system is a physical interconnection of devices that influences the behaviour of other devices or systems. ... Input devices such as sensors gather and respond to information and control a physical process by using electrical energy in the form of an output action.

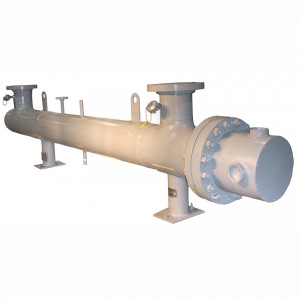

5.What type of temperature sensors are provided with the heater?

Each heater is provided with temperature sensors at the following locations:

1) on the heater element sheath to measure maximum sheath operating temperatures,

2) on the heater fange face to measure maximum exposed surface temperatures, and

3) An Exit temperature measurement is placed on the outlet pipe to measure the temperature of the medium at the outlet. The temperature sensor is a thermocouple or PT100 thermal resistance, according to customer requirements.