Industrial Electric Heater

-

Industrial Flue Gas Heater

Industrial flue gas heater

-

Industrial Skid Heater

Combine this with the extreme energy efficiency of electric heaters to maximize the cost-effectiveness of a skid system.

Applicable Industry or Industries: Oil & Gas, Mining, Chemical Processing. Benefit of Using this Skid: Heater/pump skids are able to maintain a constant temperature throughout the storage tank, preventing freezing, fallout, or stratification.

-

ATEX Certificated Process Heater

Process heaters are used to maintain heat within a liquid medium like water, oil and different chemicals along with stabilizing the gas. This process is carried out in a very careful way as a single glitch might result in drastic outcome. Another name of these types of heaters is fired heaters.

-

Over the side heater

Over the Side Heaters are a popular industrial heating product for economic and practical uses. Using a water-resistant terminal housing, these industrial heaters come in many shapes and sizes to fit within your tank dimensions and specifications.

-

Over the side heater for industry

Over-the-side heaters are ideal for heating water, oils, solvents, salts and acids. Over-the-side heater application versatility is enhanced with optional sheath materials, kilowatt ratings, terminal enclosures and mounting methods.

-

CE certificated over the side heater

Over-the-side immersion heaters are designed for installing in the top of a tank with the heated portion directly immersed along the side or at the bottom. This provides easy removal of the heater and ample working space inside the tank.

-

ATEX certificated over the side heater

Over the side immersion heaters are specifically designed such that they can be installed in the upper portion of tanks. The substance to be heated is either below the industrial tank heater or onto one side, hence the name. The main advantages of this approach are that ample space is left in the tank for other operations to take place and the heater can easily be removed when the required temperature is achieved within the substance. The heating element of an over the side process heater is usually made from steel, copper, cast alloy and titanium. A coating of fluoropolymer or quartz can be provided for protection.

-

IEC Ex certificated over the side heater

Over-the-side immersion heaters are designed for installation in the top of the tank with the heated portion directly immersed along the side or at the bottom. They take up little space, eliminate the need for tank penetrations, are easily removed for service, and provide ample working space inside the tank. Custom configured elements evenly distribute heat by direct contact in numerous applications, including acid and alkali solutions.

-

Explosion proof over the side heater

Over-the-side heaters are ideal for heating water, oils, solvents, salts and acids. Over-the-side heater application versatility is enhanced with optional sheath materials, kilowatt ratings, terminal enclosures and mounting methods.

-

Over the side heater for chemical

Over-the-side immersion heaters are designed for installation in the top of the tank with the heated portion directly immersed along the side or at the bottom. They take up little space, eliminate the need for tank penetrations, are easily removed for service, and provide ample working space inside the tank. Custom configured elements evenly distribute heat by direct contact in numerous applications, including acid and alkali solutions.

-

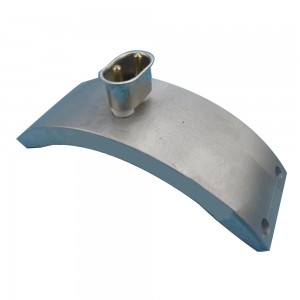

Cast in heater Cast aluminum heater

Cast Aluminum Heaters offer a high quality and efficient method of heating and controlling Extruders, Compression Molding Platens, Heat Sealers, Vacuum Forming …

-

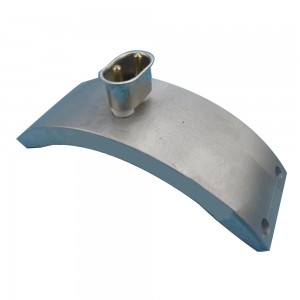

Aluminum casted heater

Aluminum casted Heaters offer a high quality and efficient method of heating and controlling Extruders, Compression Molding Platens, Heat Sealers, Vacuum Forming …