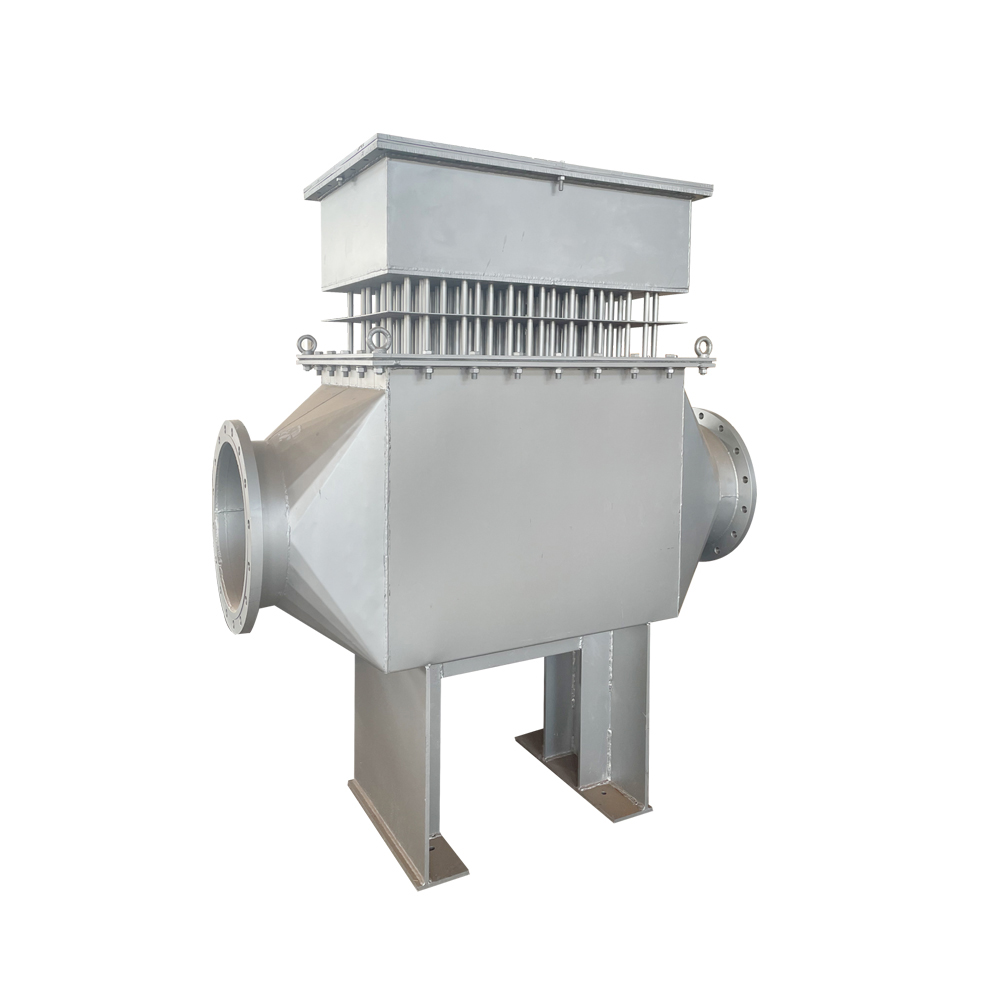

The heated medium (cold state) enters the shunt chamber through the inlet tube, so that the medium flows into the heating chamber along the inner wall of the device, through the gap of each layer of electric heating element, so that the medium is heated and heated, and then confluent into the mixed flow chamber, and then flows out of the outlet tube at a uniform temperature after mixing. A temperature sensor is installed in the mixed-flow chamber of the electric heater to collect temperature signals and transmit them to the electrical control system, and the primary circuit electrical components are controlled by the temperature regulator to achieve automatic temperature control.

When the heating element exceeds the temperature of the electric heater, the protection device automatically cuts off the power supply, and the control cabinet sends an audible and visual alarm signal (see the operation manual of the RK series electric heating control cabinet of the factory for details). When the vertical heater is used in the wellhead, when the medium changes from crude oil flow to associated air flow, the power supply will be automatically cut off due to gaseous protection, and the crude oil flow will re-enter the electric heater and immediately resume normal heating.

RXYZ type electric heater belongs to RXY series. According to some environments such as offshore platforms that do not have lifting capacity and cannot be repaired as a whole, a heater core electric heating element is divided into 3 to 15 small heating cores and combined into an integral heater. The weight of each small heater core is not more than 200 kg, the fastening bolt is not larger than M20, and it can be replaced and repaired with a simple bracket and tension hoist. The on-site maintenance height F required for each type of point heater is shown in the following table. Pay attention to leaving enough space above the electric heater when installing and designing.

Post time: Sep-07-2023