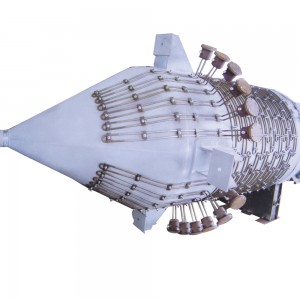

Reactor heater

The reactor is widely used in petroleum, chemical, rubber, pesticide, fuel, medicine, food, and is used to complete the pressure vessel of vulcanization, nitration, hydrogenation, alkylation, polymerization, condensation and other processes, such as reactors, reactors, decomposition pots , Polymerizer, etc.; materials generally include carbon steel, stainless steel and other materials

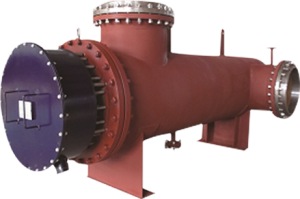

Equipped with a heating and cooling integrated container, the heat exchange area is large, the heating and cooling rate is very fast, and the demand for heat transfer oil is relatively small. It can realize continuous heating and cooling. The refrigeration heat exchanger adopts high-power plate heat exchanger, which has high heat exchange efficiency and small floor space. The whole cycle is airtight. There is no oil mist volatilization at high temperatures, and the heat transfer oil will not be oxidized and browned; at low temperatures, it will not absorb water vapor in the air; it extends the life of the heat transfer oil.

Temperature adaptive control, adaptive control system in the process of controlling the process (such as chemical reaction process), continuously adjust the PID parameters to give the process the most hao control temperature and response time, this process is through effective multi-directional measurement Temperature, temperature change and the rate of temperature change are achieved. It has the function of correcting the temperature probe PT100 of outer and inner circulation.

With self-diagnosis function, refrigerating machine overload protection, high-pressure pressure switch, overload relay, thermal protection device and other security functions, fully ensure the safety of use;

Adopt no CFC and HCFE refrigerant.

Precisely control the speed of chemical reactions.

Program function series. Non-linear and linear temperature jump function. Each step option of all programs, including controlling the outer loop program, is controlled by the PLC controller computer.

Automatic diagnosis and system monitoring function series. Through the PLC touch screen controller, the computer monitors and displays detailed system information.