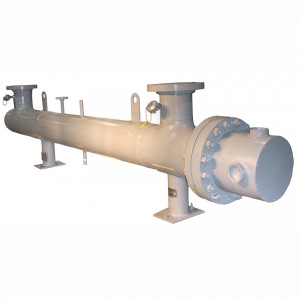

Industrial electric heater with control panel

The power can be customized

The medium is heated by electric energy through the energy conversion form of "transfer to + convection", with a thermal efficiency of 99%

The explosion-proof structure can work normally in the explosive gas dangerous places of Zone II

The structure is safe and reliable, and can be designed according to process requirements

Green and environmental protection, in line with national policies

Interlocking control of temperature, pressure, flow, etc. can be realized through the automatic control system

High temperature tracking response progress, fast response, significant energy saving

With electric heating element overheating protection function to prevent the electric heating element from being damaged due to flow interruption and accidents

The internal structure of the heater is designed according to the thermodynamic structure, without heating dead angle

| Material | Stainless steel or as required |

| Flange | DN100 |

| Vessel | Q345R/20II |

| Size | As required |

| Processing Temperature | As required |

| Design Pressure | As required |

| Operation Pressure | As required |

| Heating medium | Various of oil, water, air. etc |

| Resistance Wire | Ni80Cr20 |

Oil heating (lube oil, fuel oil, thermal oil)

Water heating (industrial heating systems)

Natural gas, seal gas, fuel gas heating

Heating of process gases and industrial gases)

Air heating (pressurized air, burner air, drying technology)

Environmental technology (exhaust air cleaning, catalytic after burning)

Steam generator, steam super heater (industrial process technology)

1.Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2.What are the available product certifications?

We have certifications such as: ATEX, CE, CNEX. IS014001, OHSAS18001,SIRA, DCI. Etc

3.How to Choose an Industrial Heater?

It is important to consider the specifics of your application prior to selecting the heater to use. Of primary concern is the type of medium being heated and the amount of heating power required. Some industrial heaters have been specially designed to function in oils, viscous, or corrosive solutions.

However, not all heaters can be used with any material. It is important to confirm the desired heater will not be damaged by the process. In addition, it is necessary to select an electric heater that is appropriately sized. Be sure to determine and verify the voltage and wattage for the heater.

One important metric to consider is Watt Density. Watt density refers to the heat flow rate per square inch of surface heating. This metric shows how densely the heat is being transferred.

4.What are the available heater fange type, sizes and materials

WNH industrial electric heater, flange size between 6"(150mm)~50"(1400mm)

Flange standard: ANSI B16.5, ANSI B16.47, DIN, JIS (Also accept customer requirements)

Flange material: Carbon steel, Stainless steel, Nickel-chromium alloy, or other required material

5.What are the available heater pressure ratings?

WNH process flange heaters are available in pressure ratings from 150 psig (10 atm)

to 3000 psig (200 atm).